A device for generating high-speed intercepting jets by using a rotating disc with holes

A technology of rotating belts and discs, used in safety devices, blade support elements, engine elements, etc., can solve problems such as affecting the safe operation of the unit, affecting the overall efficiency of the steam turbine unit, and breaking the turbine blades and shrouds, achieving flexible design. , time saving, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, structure of the present invention and working process are further described:

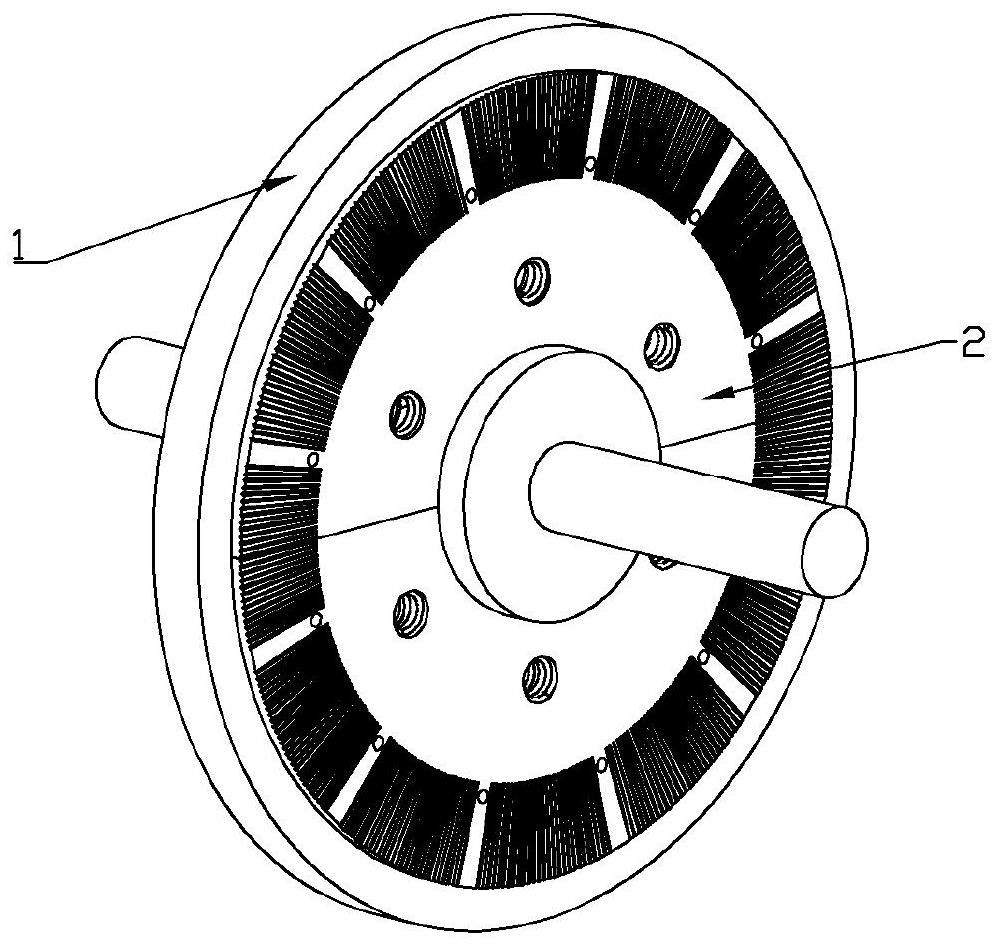

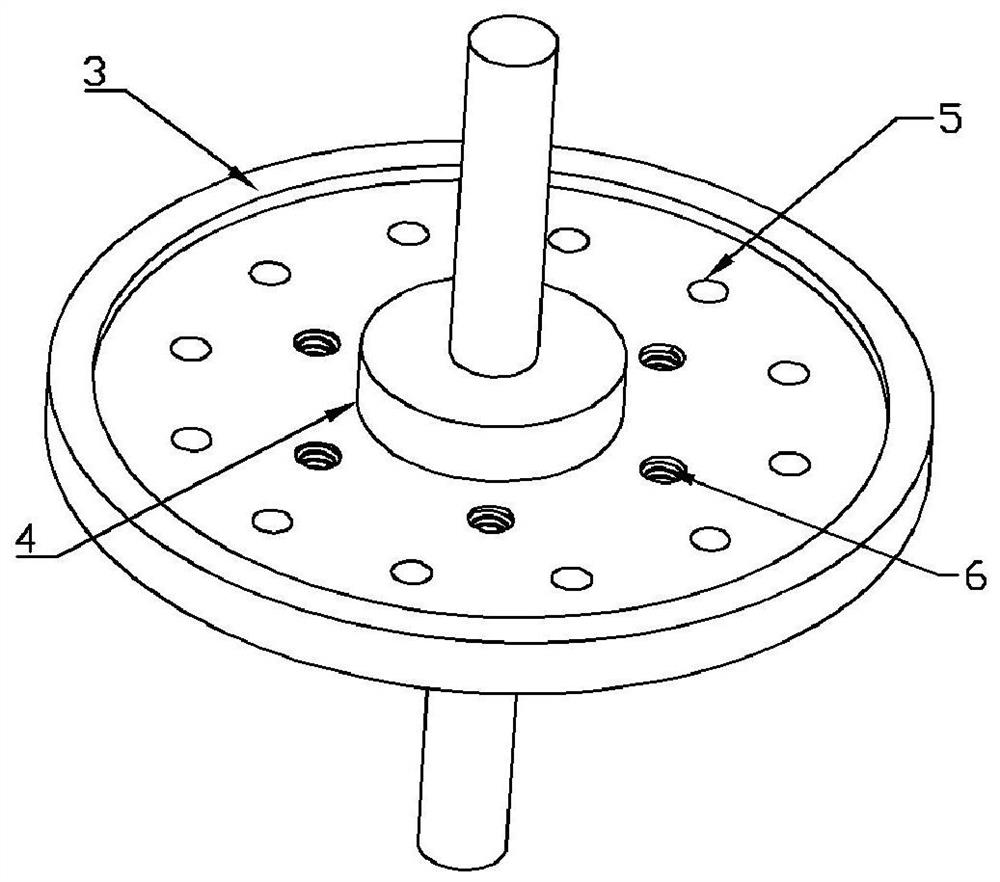

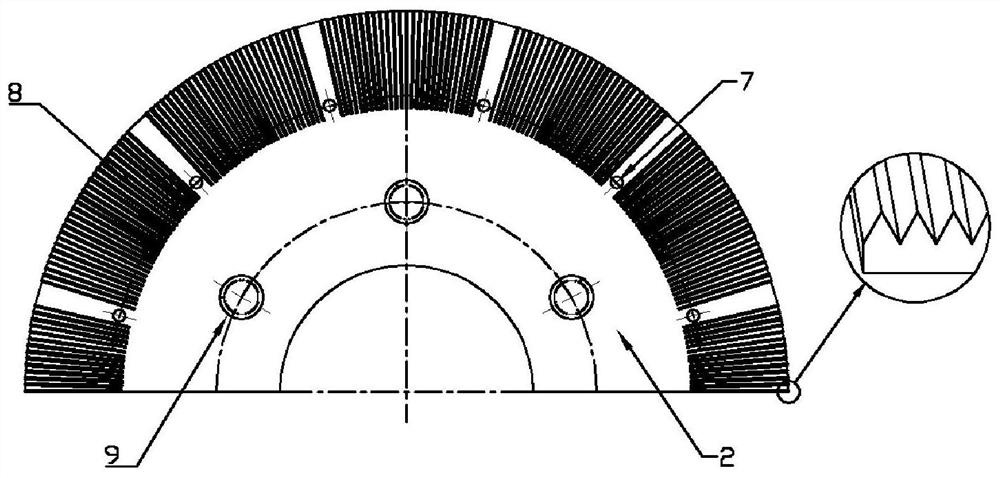

[0029] refer to Figure 1 to Figure 4 The present invention provides a device for generating high-speed intercepting jets by using a rotating disc with holes, including a main shaft 15, a fixed wheel 1 processed integrally with the main shaft 15, and two symmetrically arranged and detachable mounted on the fixed wheel 1 The perforated half disc 2 on the same end face, wherein the end face of the fixed disc 1 on which the perforated half disc 2 is installed includes a center boss for positioning the perforated half disc 2 sequentially from the center along the radial direction outward 4. The groove plane for the installation of the perforated semi-disc 2 and the 6 roulette threaded holes 6 evenly opened on it, and the 12 roulette circles set up to ensure the smooth passage of the cut-off jet and act on the material sample 13 Hole 5, and the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com