Paper pulp generating device for producing recycled paper

A generation device and recycled paper technology, which is applied in papermaking, paper recycling, textiles and papermaking, etc., can solve problems such as uneven soaking, and achieve the effects of saving soaking time, saving time, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

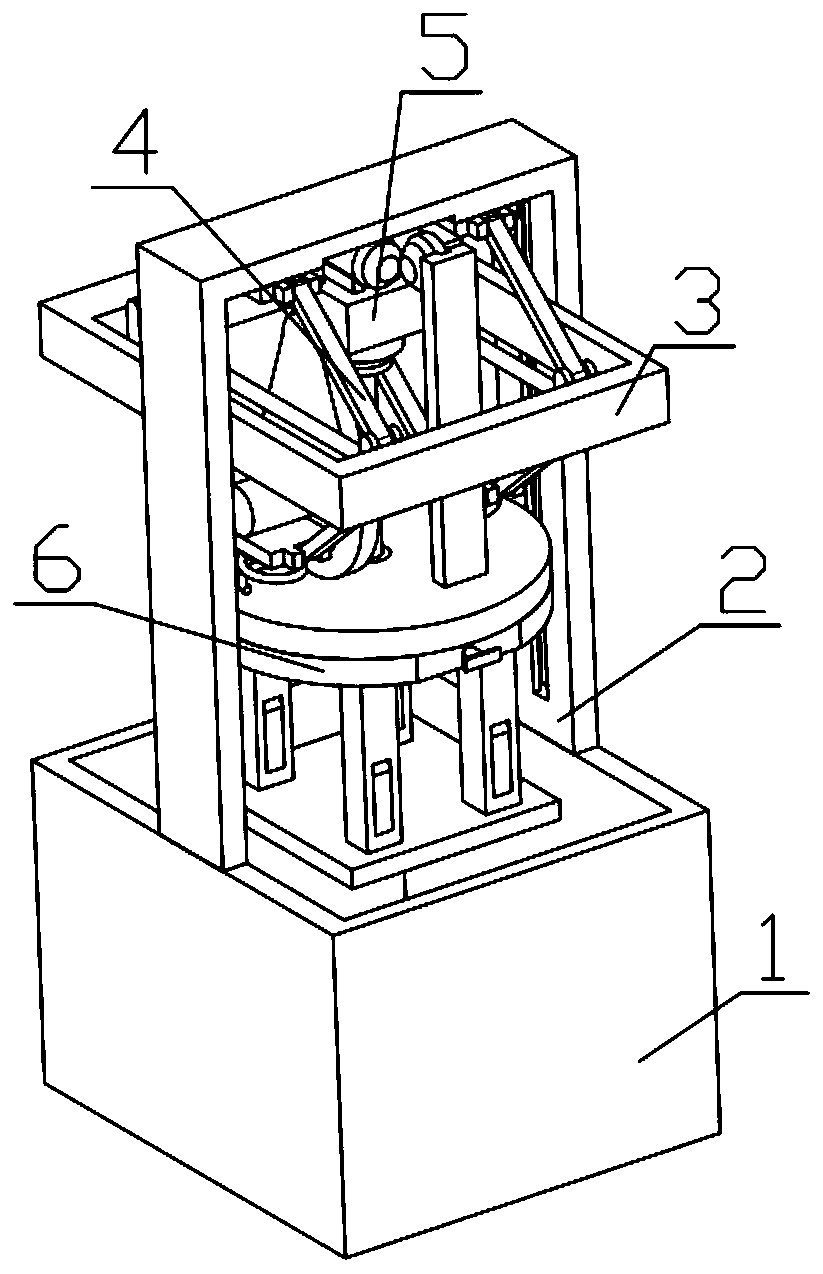

[0030] Combine below Figure 1-14 Description of this embodiment, a pulp generation device for producing recycled paper, including a box body 1, a U-shaped track frame 2, a square installation frame 3, an extension mechanism 4, a waste paper separation mechanism 5, and a stirring mechanism 6. The box body 1 is fixedly connected with the U-shaped track frame 2, the square installation frame 3 is slidably installed on the groove set on the U-shaped track frame 2, the extension mechanism 4 is fixedly installed on the U-shaped track frame 2, and the extension mechanism 4 is installed on the square installation frame 3, the stirring mechanism 6 is installed on the extension mechanism 4, and the waste paper separation mechanism 5 is installed on the stirring mechanism 6.

specific Embodiment approach 2

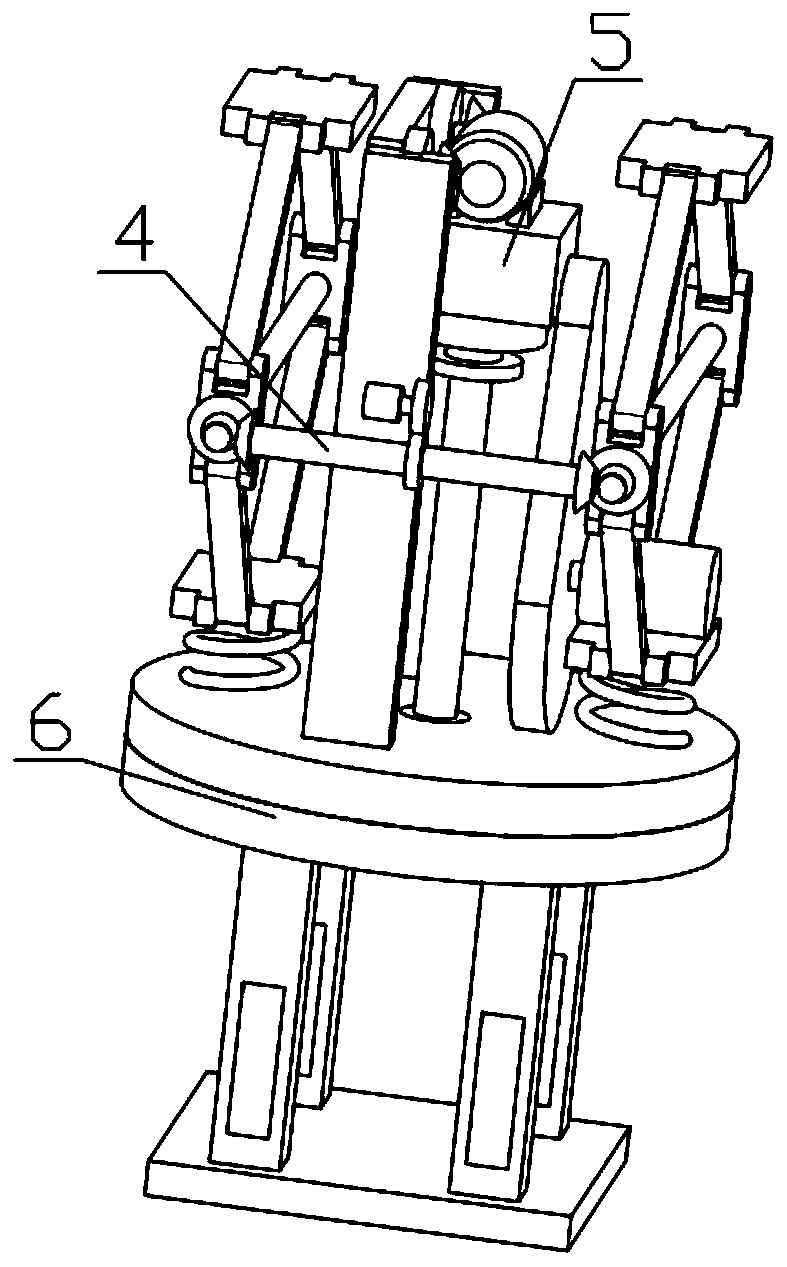

[0032] Combine below Figure 1-14This embodiment will be described. This embodiment will further explain Embodiment 1. The extension mechanism 4 includes an extension power assembly 4-1, a push frame 4-2, a toggle motor 4-3, and a cam 4-4. The component 4-1 is threadedly connected with the push frame 4-2, the cam 4-4 is fixedly installed on the output end of the toggle motor 4-3, and the toggle motor 4-3 is fixedly installed on the push frame 4-2, extending the power The component 4-1 is installed on the groove provided on the square mounting frame 3; the extended power component 4-1 includes a two-way threaded rod 4-1-1, a bevel gear ring 4-1-2, a bevel gear 4-1-3, Connecting rod 4-1-4, gear ring 4-1-5, motor gear 4-1-6, push motor 4-1-7, and motor gear 4-1-6 is fixedly installed in the push motor 4-1-7 At the output end, the gear ring 4-1-5 meshes with the motor gear 4-1-6, the connecting rod 4-1-4 is fixedly connected with the gear ring 4-1-5, and the bevel gear 4-1-3 is f...

specific Embodiment approach 3

[0034] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the first embodiment, the waste paper separation mechanism 5 includes a track toothed plate 5-1, a mounting back plate 5-2, a gear assembly 5-3, and a bidirectional motor 5-4 , Bevel gear 5-5 for displacement, square motor casing 5-6, motor 5-7 for rotation, screw 5-8, installation backplane 5-2 is fixedly connected with square casing 5-6 of motor, gear assembly 5-3 The rotation is installed on the groove provided on the installation backplane 5-2, the two-way motor 5-4 is fixedly installed on the motor square shell 5-6, and the bevel gear 5-5 for displacement is fixedly installed on the output end of the two-way motor 5-4 , the bevel gear 5-5 for displacement is meshed with the gear assembly 5-3, the gear assembly 5-3 is meshed with the rail corrugated plate 5-1, and the motor 5-7 for rotation is fixedly installed on the motor square shell 5-6. On the groove, the threaded nail 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com