Dust removal type winding machine for composite leather and working method

A working method and winder technology, applied in leather surface treatment, small raw hide/big raw hide/leather/fur treatment, leather/skin/leather/raw hide chemical treatment equipment, etc., can solve the problem of reducing the service life of equipment and increasing equipment Maintenance costs, a lot of time and other issues, to achieve the effect of reducing the amount of erosion, reducing labor costs, and less negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

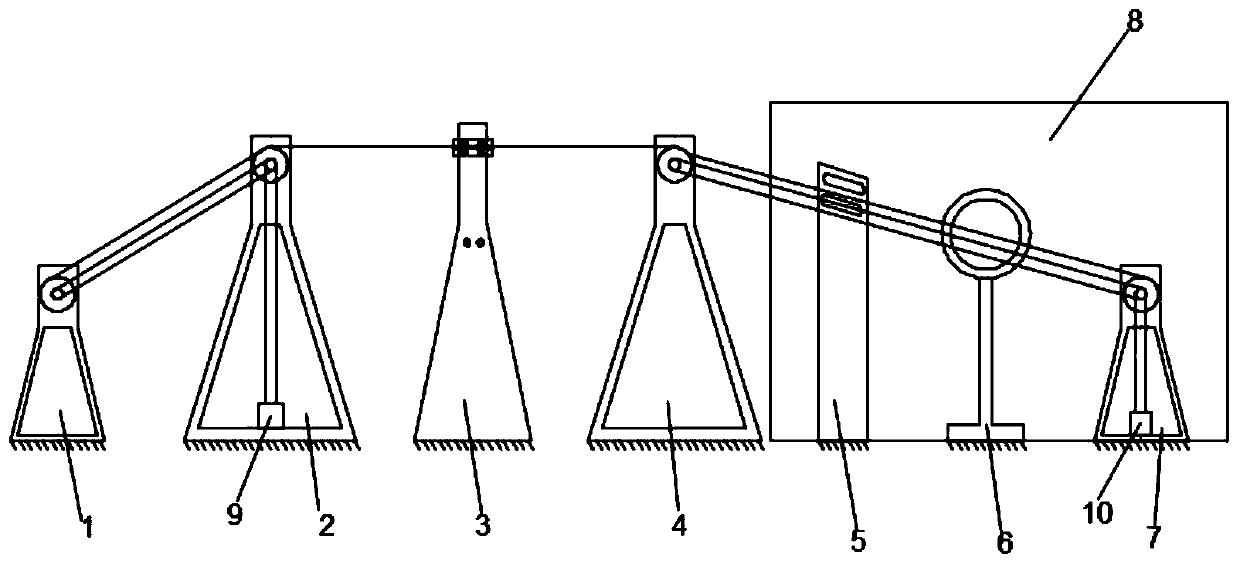

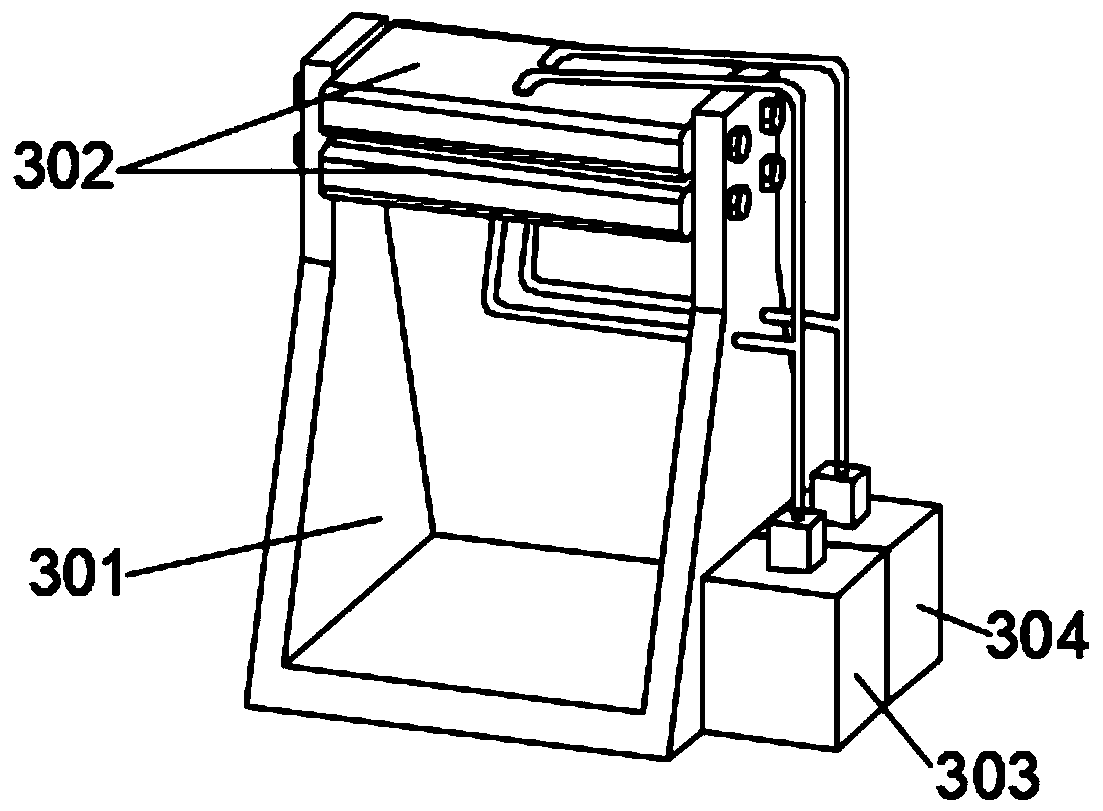

[0030] Such as figure 1 The shown dust-proof cloth rolling machine for composite leather includes a feeding roller 1 fixedly connected to the ground through a bracket, a first roller shaft 2, a cleaning assembly 3, a second roller shaft 4, a wiping assembly 5 and a winding Roller 7, the first roll shaft 2 is located at the output end of the feed roll 1, the second roll shaft 4 is located at the output end of the first roll shaft 2, and the winding roll 7 is located at the output end of the second roll shaft 4 , the cleaning assembly 3 is located between the first roller shaft 2 and the second roller shaft 4, the wiping assembly 5 is located between the second roller shaft 4 and the winding roller 7, and the winding roller 7 is connected to the second roller shaft through a belt drive. Motor 10 and second roller shaft 4.

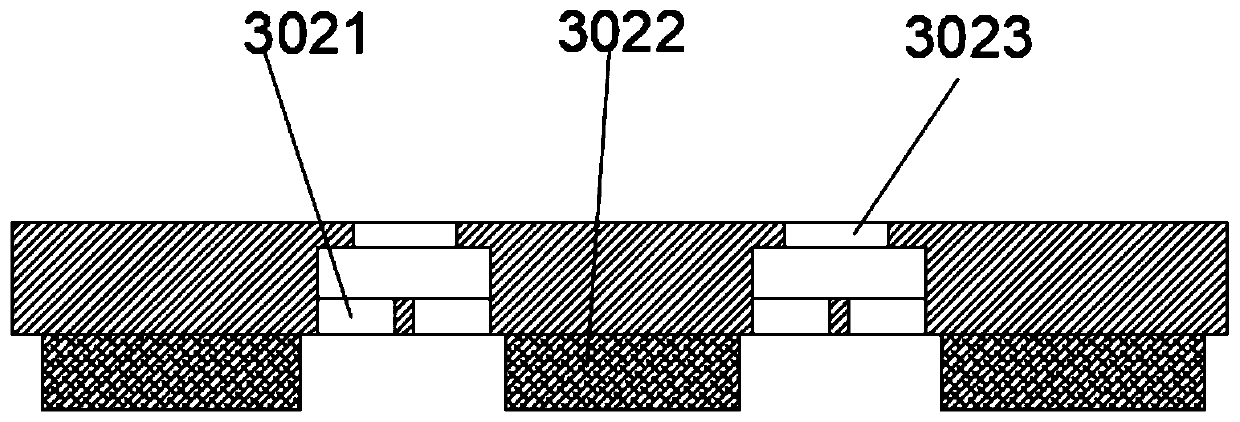

[0031] Such as figure 1 and Figure 5 As shown, in the above-mentioned dust-proof cloth rolling machine for composite leather, the first roller shaft 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com