Double-power-source electric drive assembly with load balancing device

A technology of load balance and dual power sources, which is applied to the layout of multiple different prime movers, power devices, and air pressure power devices of general power devices, which can solve the difference in motor manufacturing errors and increase the difficulty of control. Driver fatigue To avoid problems such as road load differences, etc., to increase the output torque difference, improve handling stability, and reduce wheel out-of-synchronization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

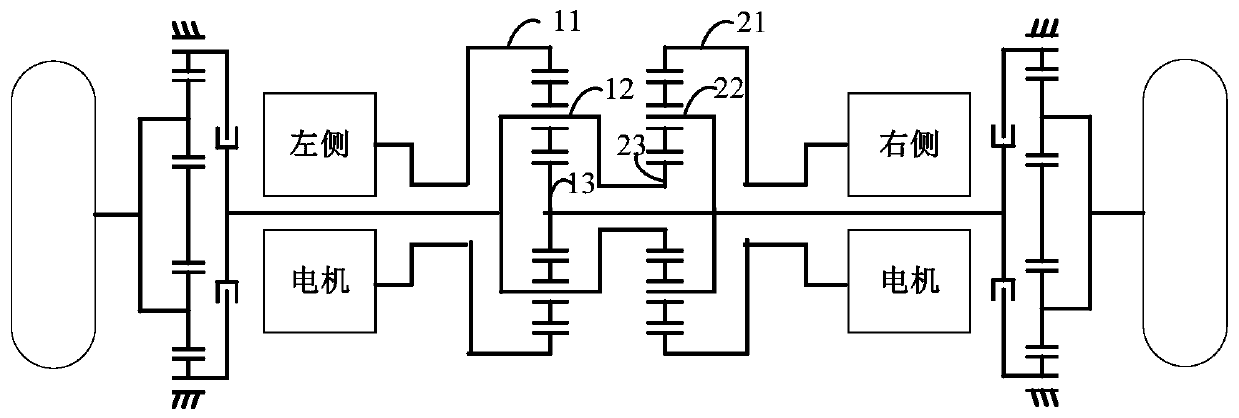

[0019] A dual power source electric drive assembly with a load balancing device of the present invention includes a left motor 1, a right motor 2, a load balancing device 3, a left speed change mechanism 4 and a right speed change mechanism 5;

[0020] The left motor 1, the right motor 2, the load balancing device 3, the left speed change mechanism 4 and the right speed change mechanism 5 are coaxially arranged; the output shaft of the left motor 1 is connected to the left side of the load balance device 3. The side input shaft is connected or integrated, the output shaft of the right motor 2 is connected or integrated with the right input shaft of the load balancing device 3, and the left output shaft of the load balancing device 3 is connected with the left side The input shaft of the transmission mechanism 4 is connected or integrated, and the right out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com