Automatic ham sausage slicing machine for catering

A ham sausage and slicer technology, applied in metal processing and other directions, can solve problems such as safety accidents, ham sausages are easily damaged, unsafe, etc., and achieve the effect of avoiding safety accidents and fast slicing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

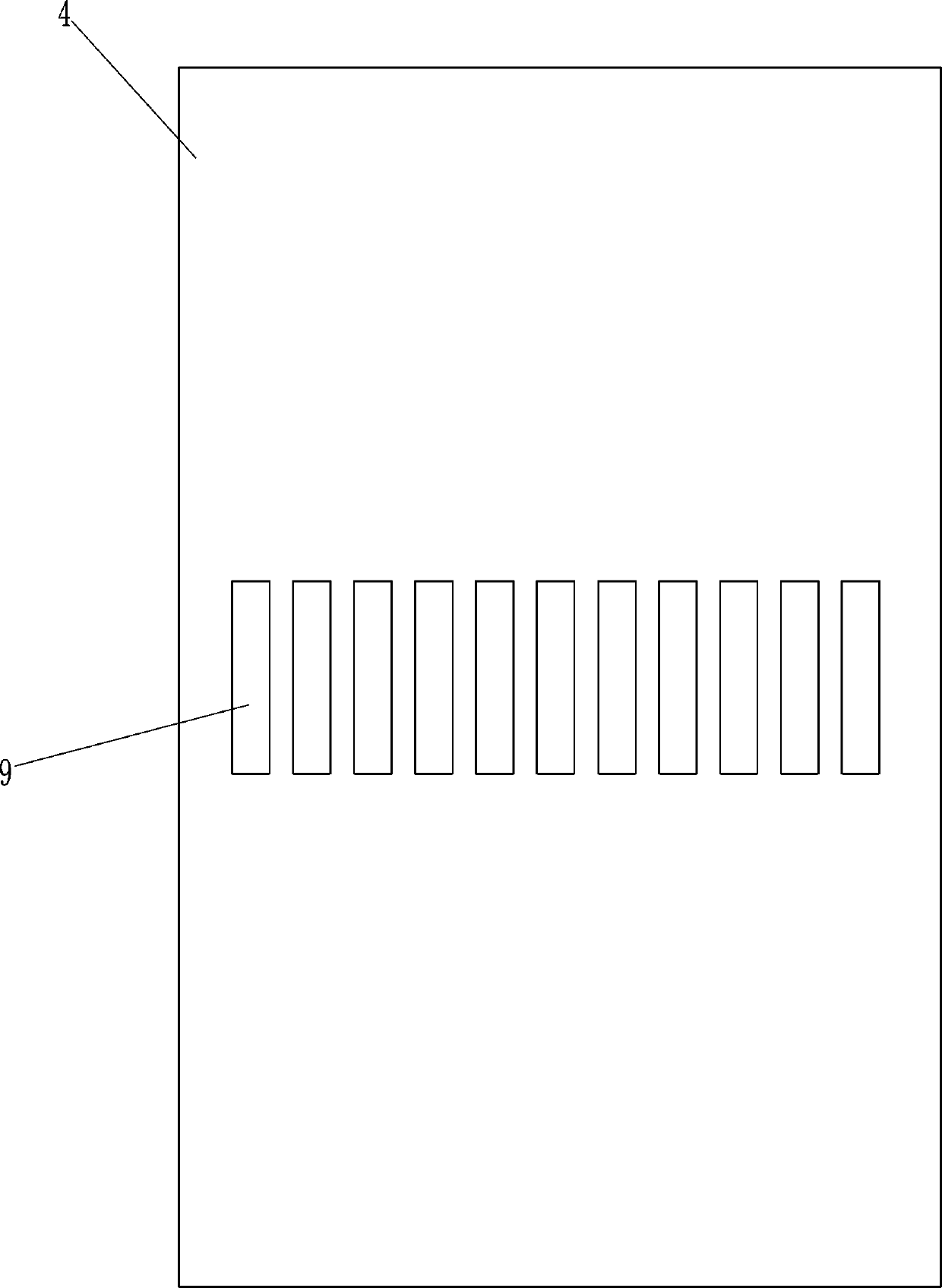

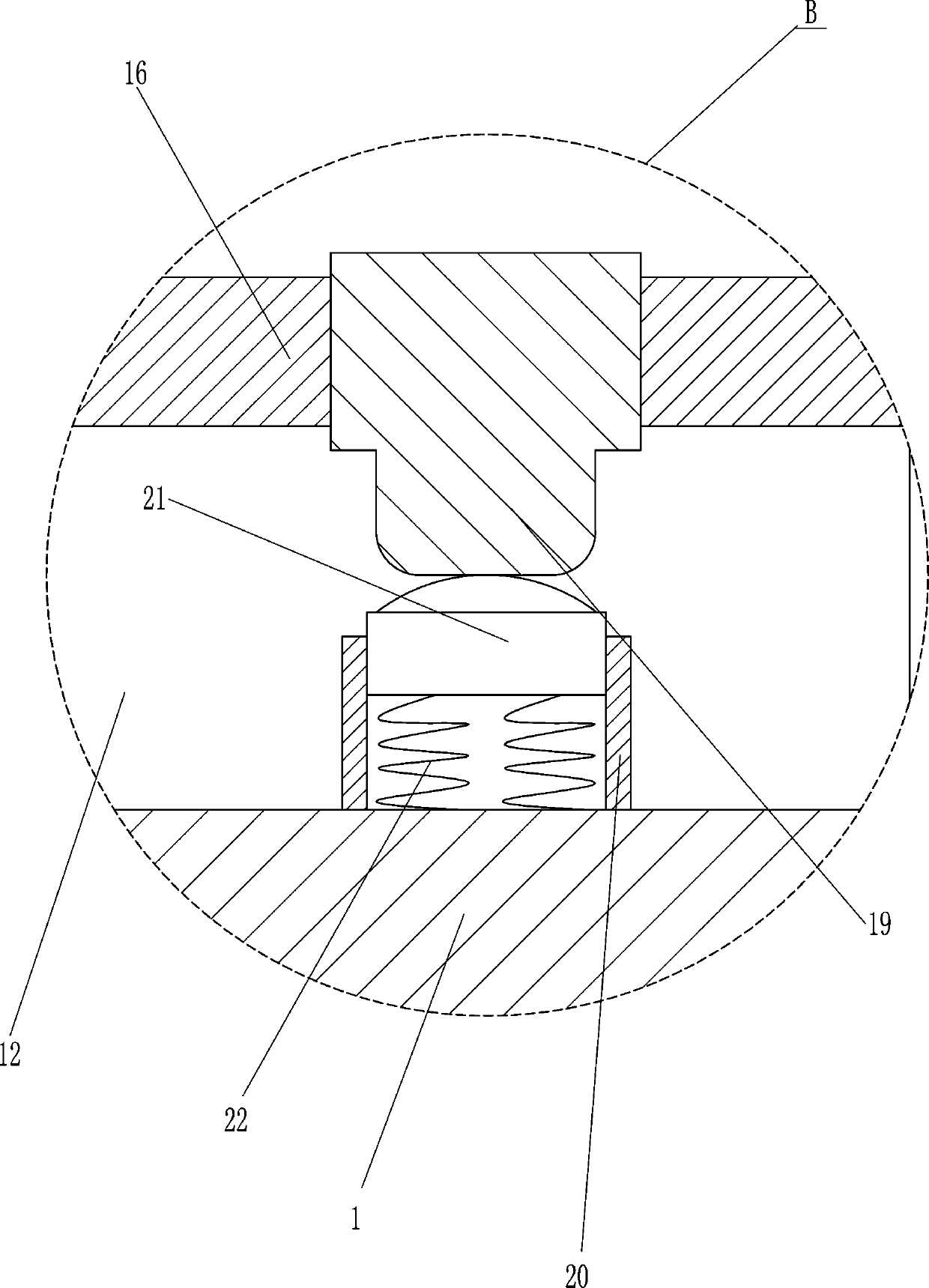

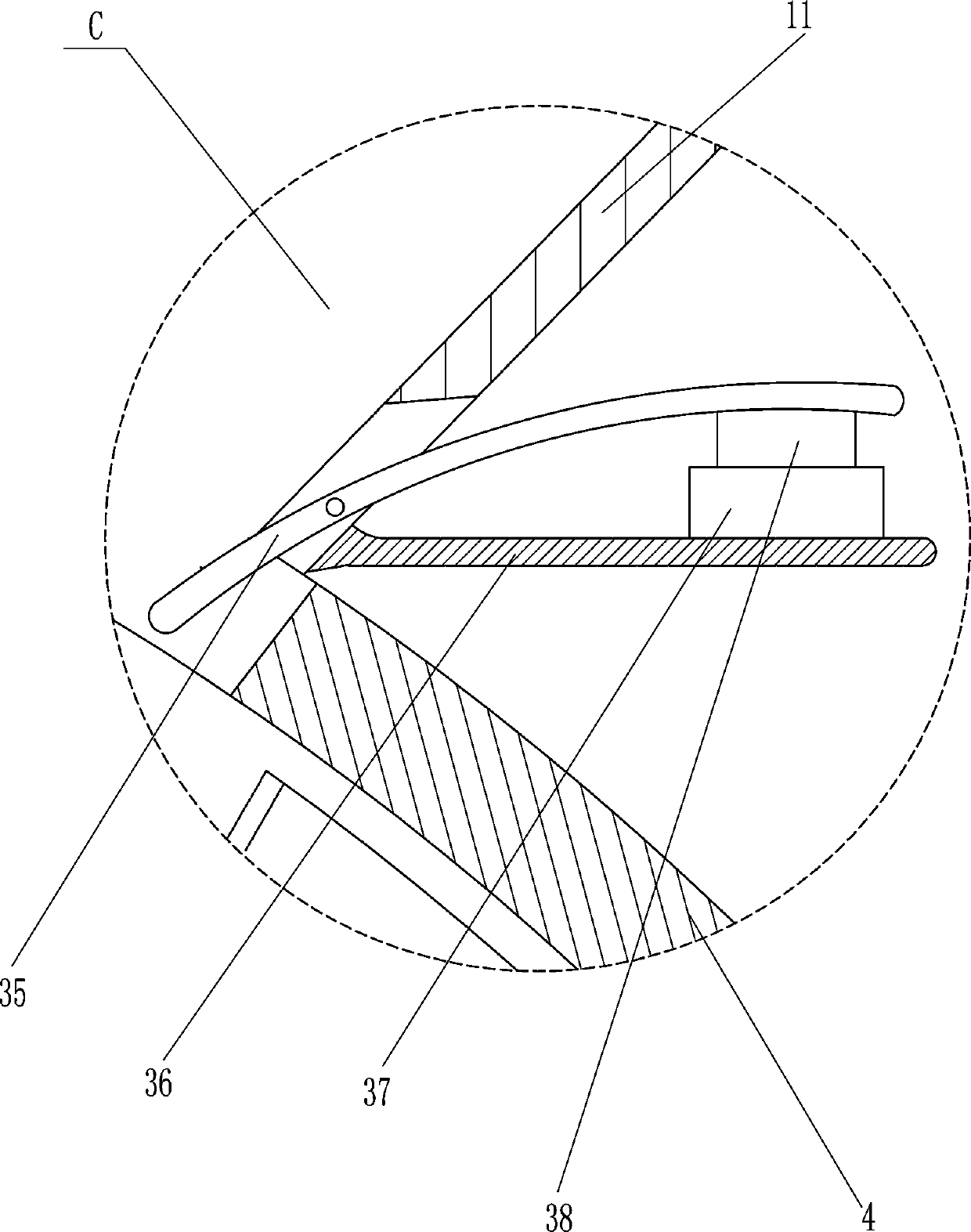

[0019] An automatic ham sausage slicer for catering, such as Figure 1-4 As shown, it includes a bracket 1, a leg 2, a rotating shaft 3, a disk-shaped housing 4, a rotating plate 5, a funnel 11, a first support 12, a motor 13, a bevel gear 14, a first bushing 15, and a first rotating rod 16 , worm 17, worm wheel 18, rotating plate 19, slide plate 20, first button 21, spring 22, discharge port 23, collecting frame 24 and slicing mechanism 25, the bottom and left sides of the bracket 1 are provided with legs 2, the bracket 1 It is connected with the outrigger 2 by welding connection. A disk-shaped shell 4 is provided on the left side of the top of the bracket 1. The disk-shaped shell 4 is rotatably provided with a rotating shaft 3 at the center of the circle. Inside the shell 4, a plurality of feeding troughs 6 are evenly spaced on the outside of the turntable 5. The feeding trough 6 is provided with a knife slot 7, the left side of the disk shell 4 is provided with a knife hole...

Embodiment 2

[0021] An automatic ham sausage slicer for catering, such as Figure 1-4 As shown, it includes a bracket 1, a leg 2, a rotating shaft 3, a disk-shaped housing 4, a rotating plate 5, a funnel 11, a first support 12, a motor 13, a bevel gear 14, a first bushing 15, and a first rotating rod 16 , worm 17, worm wheel 18, rotating plate 19, slide plate 20, first button 21, spring 22, discharge port 23, collecting frame 24 and slicing mechanism 25, the bottom and left sides of the bracket 1 are provided with legs 2, the bracket 1 A disk-shaped casing 4 is provided on the left side of the top, and a rotating shaft 3 is arranged at the center of the disk-shaped casing 4. The rotating shaft 3 is provided with a turntable 5. A plurality of feeding troughs 6, a knife groove 7 is opened on the feeding groove 6, a knife hole 9 is opened on the left side of the disk-shaped shell 4, a feeding port 10 is opened on the upper right of the disk-shaped shell 4, and the right side of the disk-shape...

Embodiment 3

[0024] An automatic ham sausage slicer for catering, such as Figure 1-4 As shown, it includes a bracket 1, a leg 2, a rotating shaft 3, a disk-shaped housing 4, a rotating plate 5, a funnel 11, a first support 12, a motor 13, a bevel gear 14, a first bushing 15, and a first rotating rod 16 , worm 17, worm wheel 18, rotating plate 19, slide plate 20, first button 21, spring 22, discharge port 23, collecting frame 24 and slicing mechanism 25, the bottom and left sides of the bracket 1 are provided with legs 2, the bracket 1 A disk-shaped casing 4 is provided on the left side of the top, and a rotating shaft 3 is arranged at the center of the disk-shaped casing 4. The rotating shaft 3 is provided with a turntable 5. A plurality of feeding troughs 6, a knife groove 7 is opened on the feeding groove 6, a knife hole 9 is opened on the left side of the disk-shaped shell 4, a feeding port 10 is opened on the upper right of the disk-shaped shell 4, and the right side of the disk-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com