Automatic profile bending device, method for realizing three-dimensional bending by using device and application

A bending device and profile technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of long bending time, early fatigue life of fixed parts, low bending accuracy, etc., and achieve consistent deformation effect and deformation accuracy. High, high bending efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

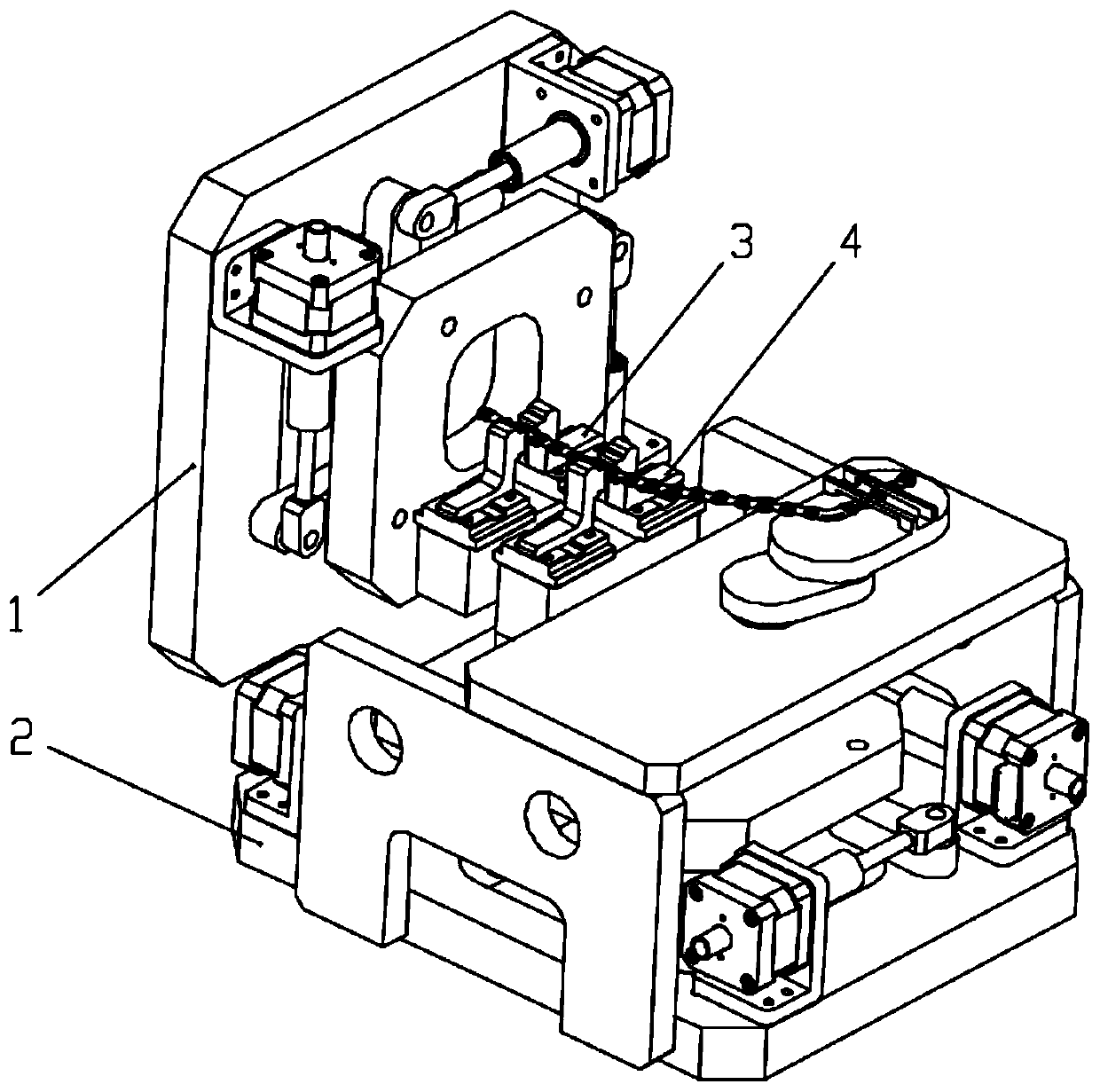

[0042] In this embodiment, the profile automatic bending device such as figure 1 As shown, a first motion mechanism 1 and a second motion mechanism 2 are included.

[0043] Such as figure 2 As shown, the first clamping mechanism 3 is provided on the first moving mechanism 1 .

[0044] Such as image 3 As shown, the second moving mechanism 2 is provided with a first clamping mechanism 4 .

[0045] Such as figure 2 , 3 As shown, the mechanism of the first motion mechanism 1 and the second motion mechanism 2 are exactly the same, both are 3-PRR parallel motion mechanisms, driven by a closed stepping screw motor, which can drive to realize two-dimensional motion and rotation in the plane sports.

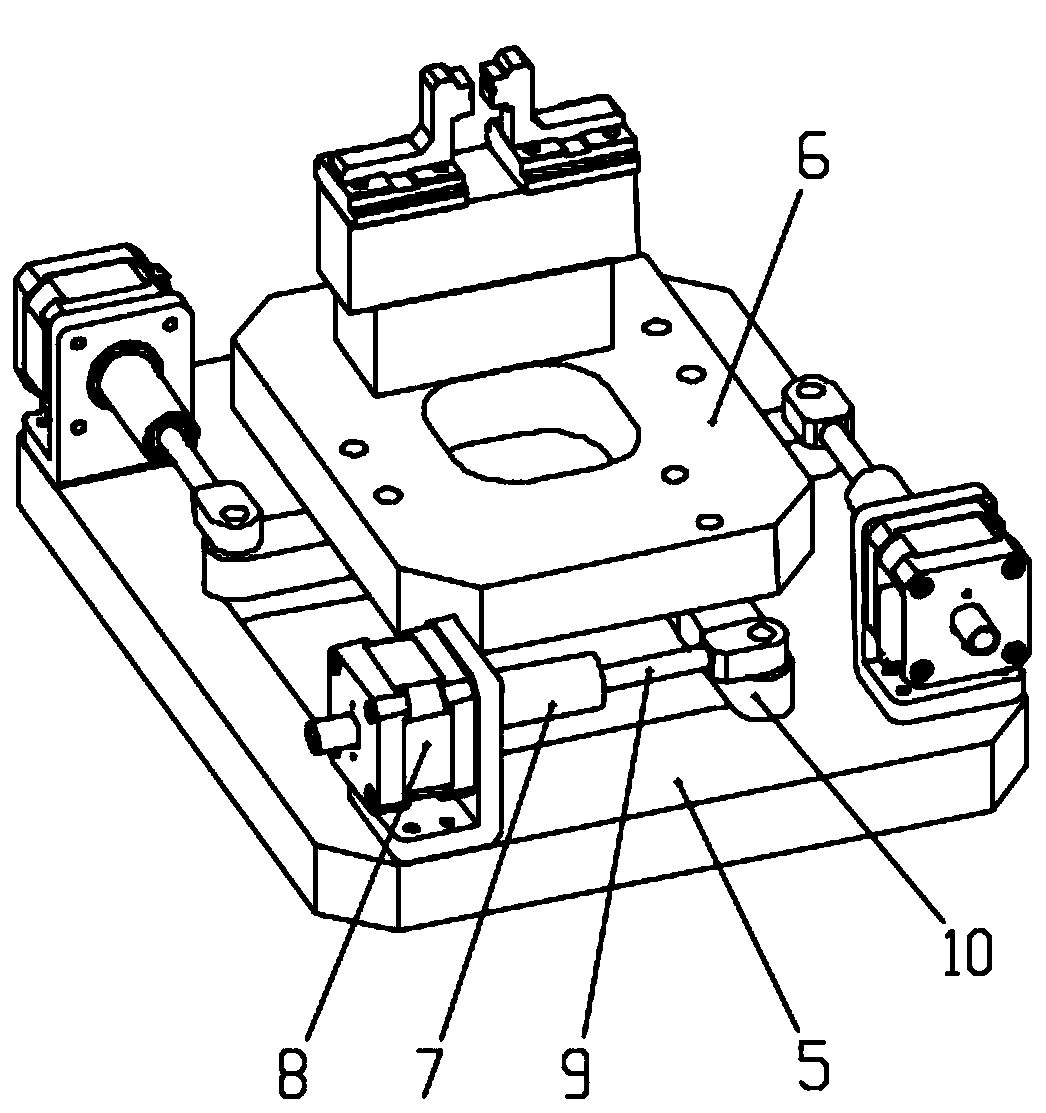

[0046] Such as figure 2 As shown, the 3-PRR parallel kinematic mechanism includes a base, a moving platform 6 on the base 5 and three transmission mechanisms 7 . Each transmission mechanism includes a closed-type stepping screw motor 8, a P-width driving element 9, a connectin...

Embodiment 2

[0056] In this embodiment, the profile automatic bending device is exactly the same as that in Embodiment 1.

[0057] The automatic deformation device is used for the repair of the patient's jawbone. The modification method is: according to the 3D model of the patient's jawbone, the titanium alloy material is bent through the device to match the 3D model of the patient's jawbone. The bone model is consistent.

[0058] The method of bending titanium alloy material with this device is as follows:

[0059] (1) At the initial position, the first clamping machine and the second clamping mechanism fix different positions of the titanium alloy plate through the clamping part, that is, the first clamping mechanism clamps the A position of the titanium alloy plate, and the second clamping mechanism The mechanism clamps the B position of the titanium alloy plate;

[0060] (2) Carry out the following process a, process b, or process a and process b, so that the position A and position ...

Embodiment 3

[0067] In this embodiment, the profile automatic bending device is basically the same as in Embodiment 1, the difference is that in this embodiment, such as Figure 4 As shown, the profile automatic bending device also includes an auxiliary feeding mechanism, including a base 11, a first connecting rod 12, a second connecting rod 13 and a rotary motion pair 14, and the rotary motion pair 14 is connected to the base 11 through the first connecting rod 12 On, the second connecting rod 13 is fixed on the rotary kinematic pair 14. In the working state, the displacement of the unclamped part of the material in the plane is adjusted by the rotary motion pair, so that the position of the unclamped part is kept in a direction that is conducive to the feeding of the clamped part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com