Contact focusing type medical piezoelectric ultrasonic transducer and preparation method

A piezoelectric ultrasonic and transducer technology, applied in the direction of fluid using vibration, etc., can solve the problem that the bandwidth and sensitivity of the transducer are not optimal, the performance of the final product is difficult to effectively control, and the manufacturing process of the transducer is unstable. and other problems, to achieve the effect of improving picture quality, lateral resolution improvement, and good vibration characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

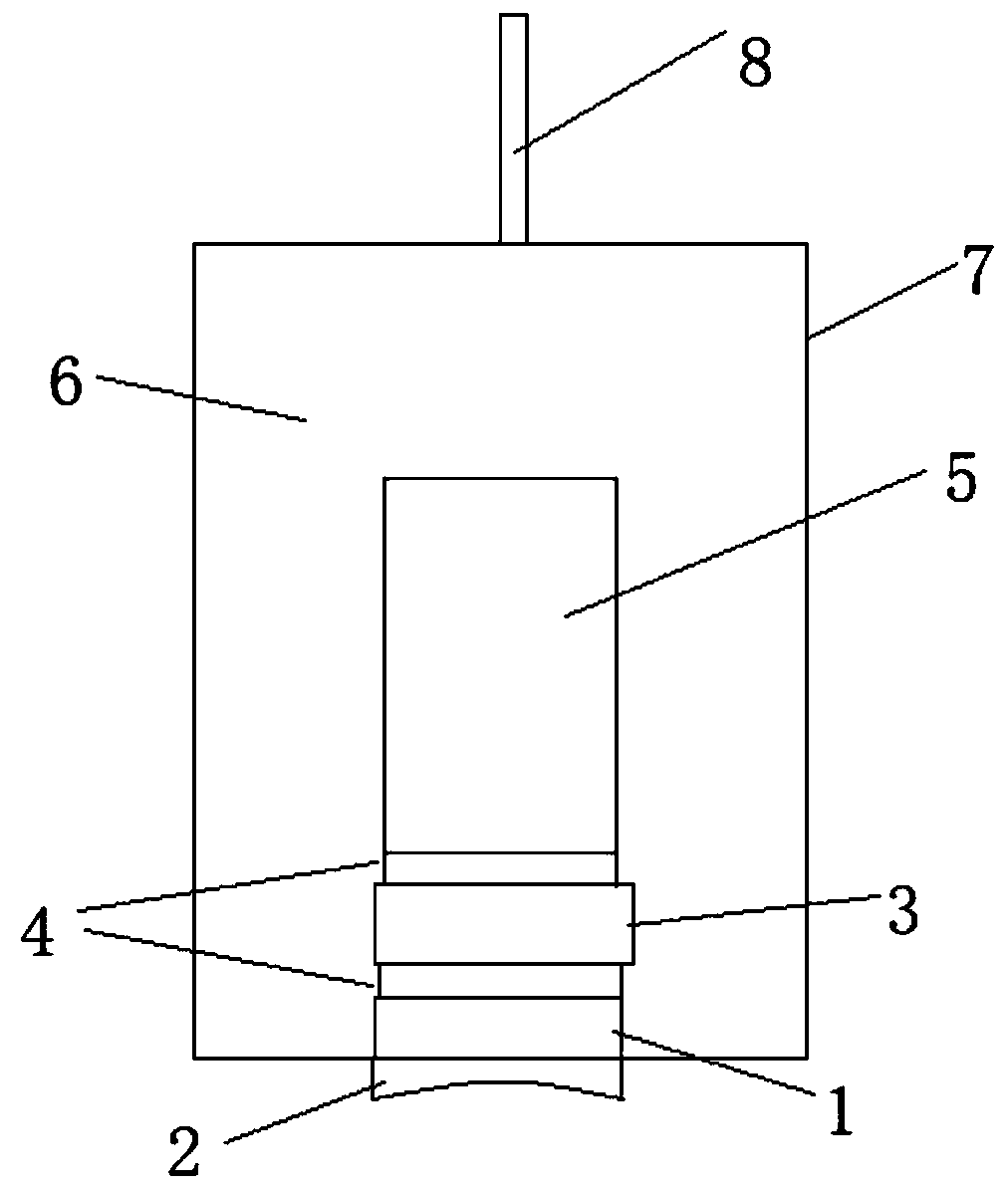

[0042] see figure 1 , a contact focused medical piezoelectric ultrasonic transducer, comprising: a housing 7, a second matching layer 2, and a backing block 5, a piezoelectric layer 3, first matching layer 1;

[0043] The first matching layer 1 is a magnesium alloy layer, the second matching layer 2 is a concave acoustic lens of epoxy resin, the thickness of the first matching layer 1 and the second matching layer 2 are both a quarter of the working wavelength of the transducer, The upper surface and the lower surface of the piezoelectric layer 3 are provided with electrodes 4, the backing block 5 is fixed on the upper surface of the piezoelectric layer 3, the first matching layer 1 is fixed on the lower surface of the piezoelectric layer 3 and is electrically connected thereto, the first The matching layer 1 is also electrically connected to the housing 7 , and the second matching layer 2 is fixed on the lower surface of the first matching layer 1 .

[0044] Wherein, the ma...

Embodiment 2

[0058] see figure 1 , the present embodiment provides a contact-focused medical piezoelectric ultrasonic transducer preparation method based on embodiment 1, comprising the following steps:

[0059] S1: Using piezoelectric ceramics as the piezoelectric layer 3, and forming electrodes 4 on the upper and lower surfaces of the piezoelectric layer 3 by being treated with silver;

[0060] S2: using a magnesium alloy as the first matching layer 1, and fixing the upper surface of the first matching layer 1 to the lower surface of the piezoelectric layer 3;

[0061] S3: Configure and stir according to the proportioning material of the backing block 5. After curing, cut the cured backing block 5 into the required size and fix it on the upper surface of the piezoelectric layer 3, wherein the backing block The proportioning material of 5 is the proportioning material of resin: tungsten powder: glass ball=1:4:0.5;

[0062] S4: Put the fixed backing block 5, the piezoelectric layer 3 and...

Embodiment 3

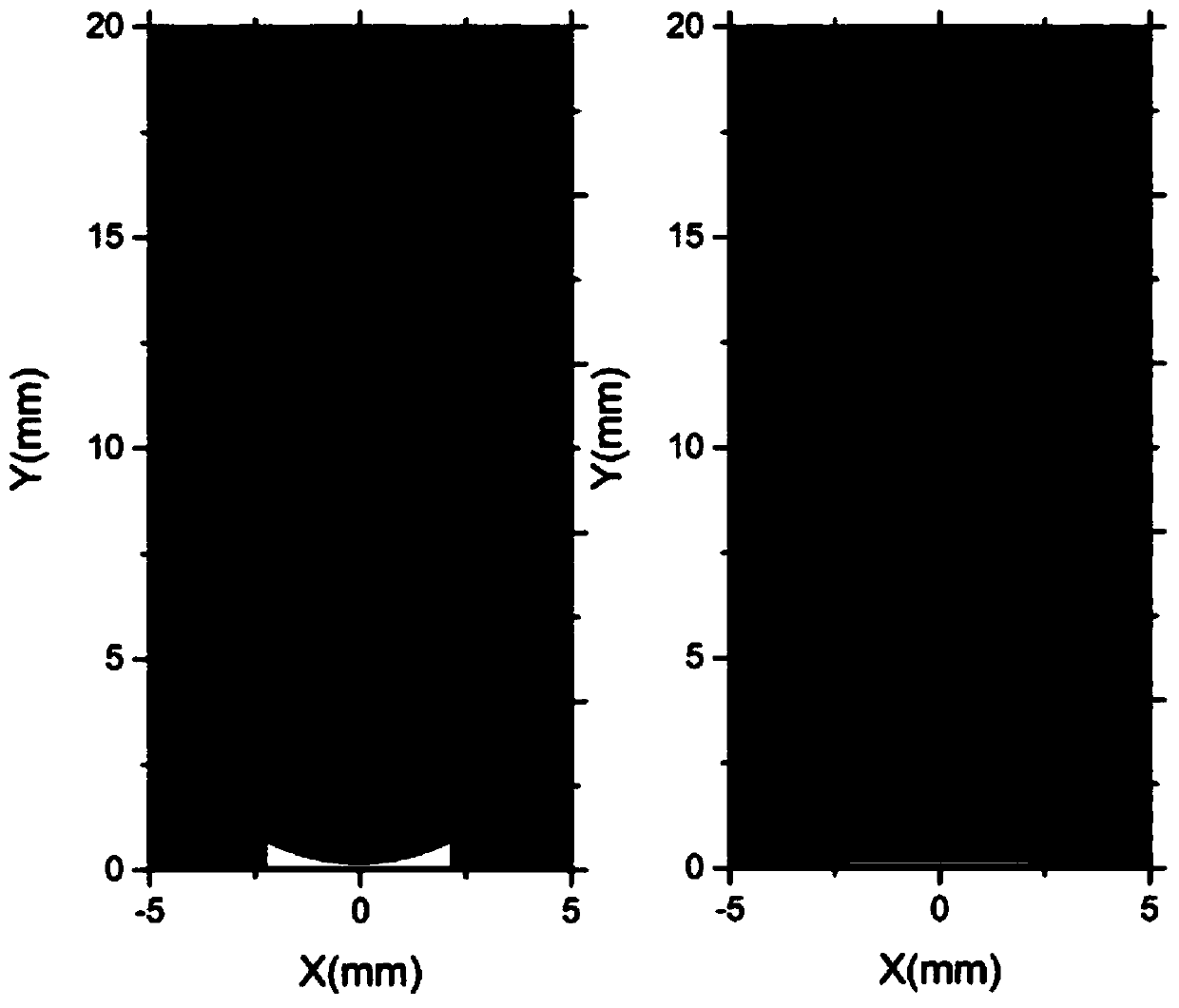

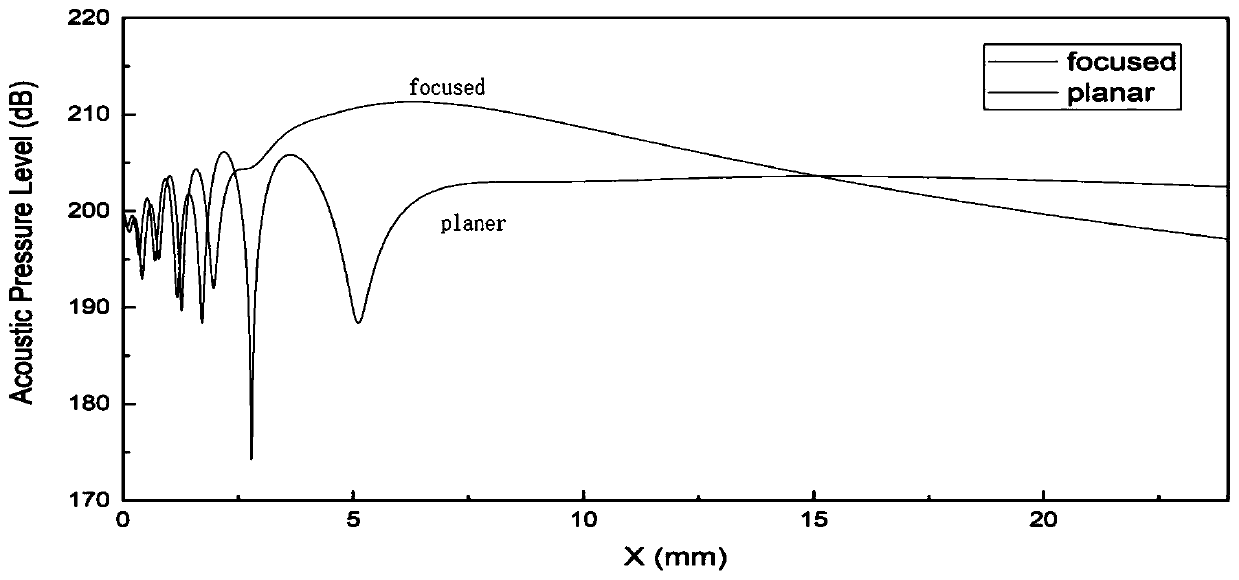

[0077] see figure 1 , This embodiment provides a 10 MHz single-element focused ultrasonic transducer based on Embodiment 1 with an AZ31B magnesium alloy as the first matching layer. The device adopts the structure required by any one of Embodiment 1. In this embodiment, the piezoelectric layer 3 is made of PZT-5h ceramics with a diameter of 2.3 mm and a thickness of 0.2 mm. The diameter of the first matching layer magnesium alloy AZ31B is 2.3mm, the thickness is 160μm, and the size of the backing block 5 is 2.3*2.3mm 2 , the thickness is 2mm, and the center thickness of the thinnest part of the second matching layer Epo-Tek301 concave acoustic lens is 65μm. It is calculated that the radius of curvature of this embodiment is 3 mm, and the value of the focal length f is 6.9 mm. The resonance frequency measured by the impedance analyzer is 9.23MHz, the anti-resonance frequency is 11.52MHz, and the effective electromechanical coupling coefficient K is calculated eff is 0.59. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Center thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com