Nitrogen-doped attapulgite/carbon/bismuth oxybromide composite nitrogen fixation photocatalyst and preparation method and application thereof

A technology of attapulgite and bismuth oxybromide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, preparation/separation of ammonia, etc., which can solve the problem of large energy consumption and achieve cost reduction Low cost, simple process, and the effect of improving charge transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

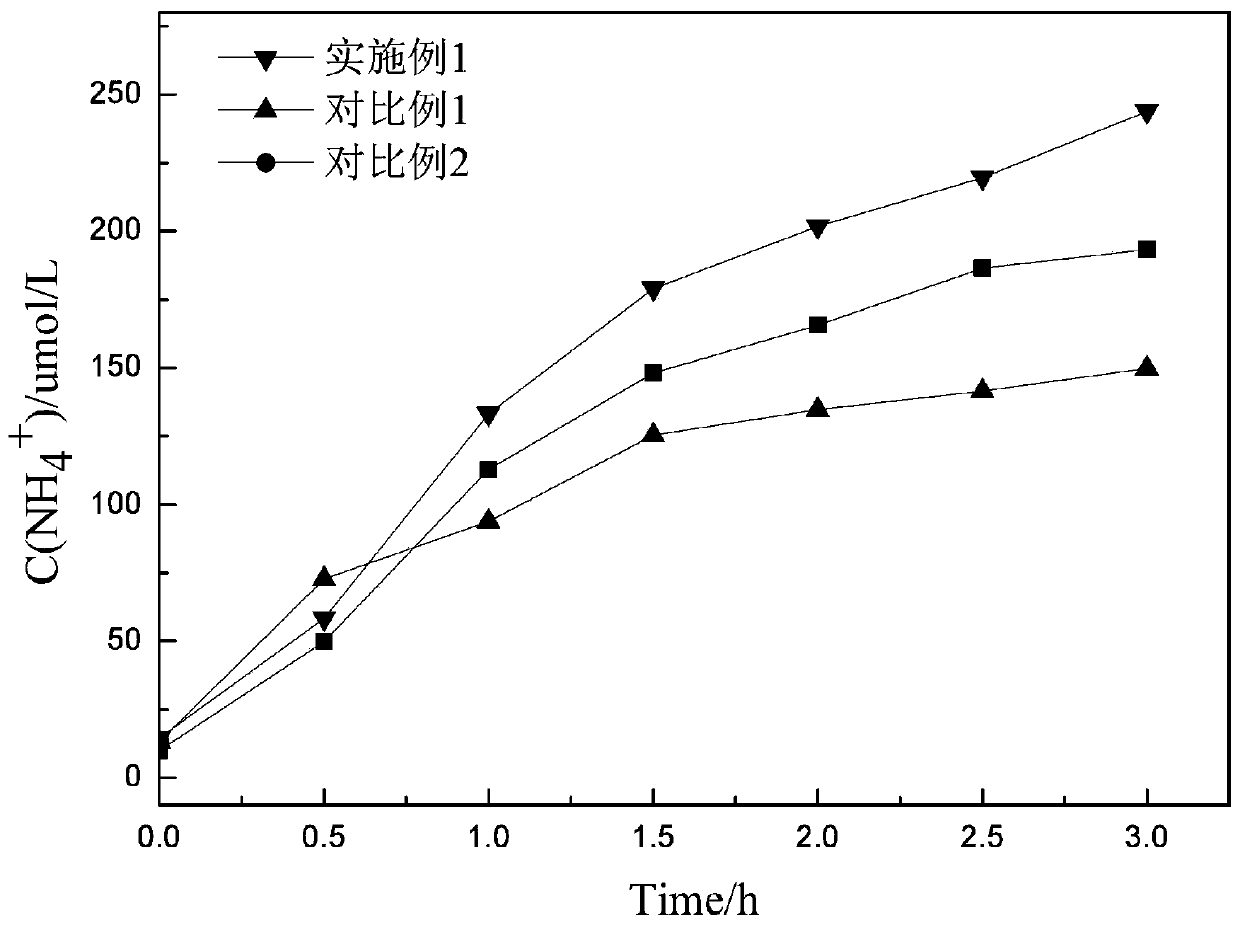

Embodiment 1

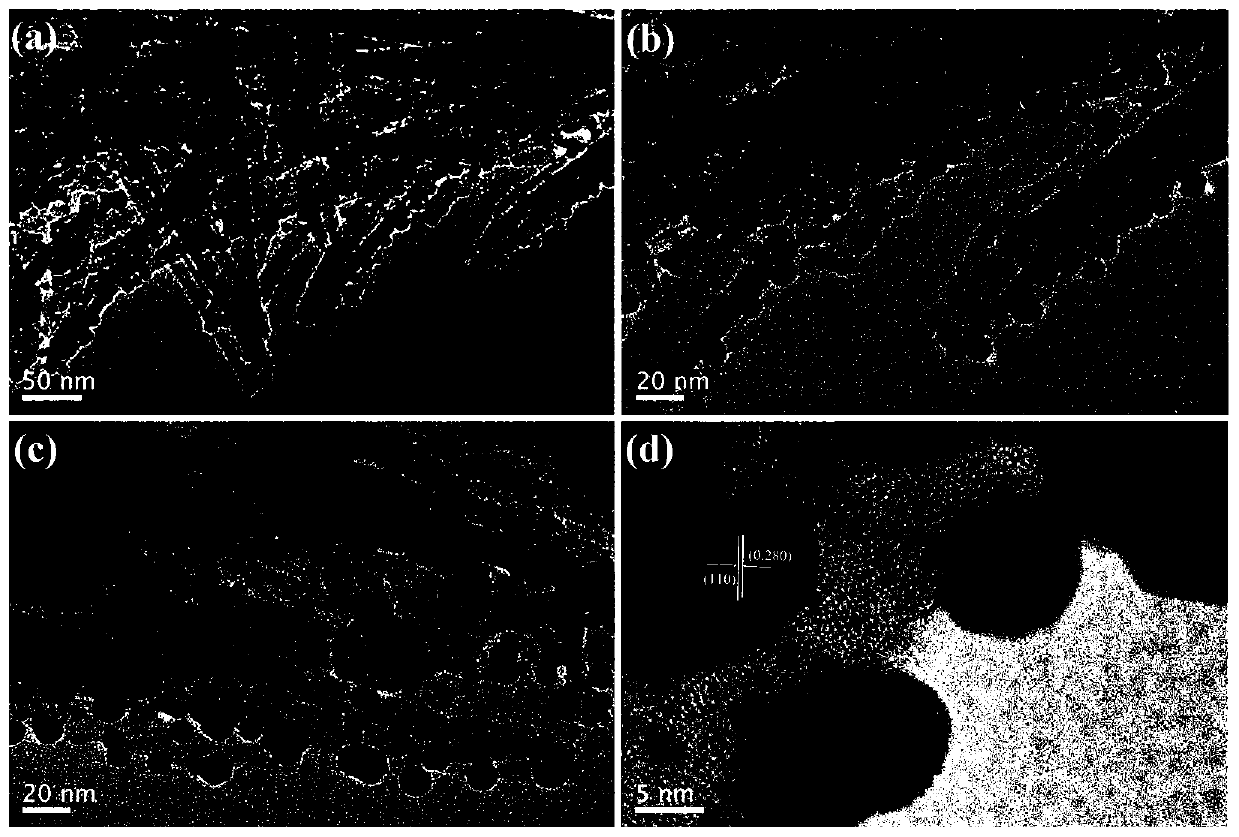

[0027] (1) Take 3g of attapulgite and 1mL of aniline and evenly disperse in 50mL of aqueous solution (solid-to-liquid ratio of attapulgite to aniline (g / mL)=3:1), transfer the system to 0°C and stir for 24h, in-situ polymerization Attapulgite / polyaniline composite material was obtained. Further calcined carbonization (900℃ / 2h, N 2 ), the nitrogen-doped attapulgite / carbon precursor material can be obtained.

[0028] (2) Weigh 91.5 mg of nitrogen-doped attapulgite / carbon prepared in step (1) and 0.119 g of potassium bromide, dissolve in 30 mL of aqueous solution and sonicate for 15 min to obtain a uniform suspension.

[0029] (3) Weigh 0.485 g of bismuth nitrate pentahydrate and disperse it in 20 mL of glycerin with magnetic stirring for 0.5 h to dissolve it to prepare a bismuth nitrate solution.

[0030] (4) The solution prepared in step (2) was slowly added dropwise to step (3) under magnetic stirring conditions, after the dropwise addition was completed and vigorously stirr...

Embodiment 2

[0033] (1) Take 3g of attapulgite and 1mL of aniline and evenly disperse in 50mL of aqueous solution (solid-to-liquid ratio of attapulgite to aniline (g / mL) = 3:1), transfer the system to 0°C and stir for 12h, in situ polymerization Attapulgite / polyaniline composite material was obtained. Further calcined carbonization (900℃ / 2h, N 2 ), the nitrogen-doped attapulgite / carbon precursor material can be obtained.

[0034] (2) Weigh 152.5 mg of nitrogen-doped attapulgite / carbon prepared in step (1) and 0.119 g of potassium bromide, dissolve in 30 mL of aqueous solution and sonicate for 15 min to obtain a uniform suspension.

[0035] (3) Weigh 0.485 g of bismuth nitrate pentahydrate and disperse it in 20 mL of glycerin with magnetic stirring for 0.5 h to dissolve it to prepare a bismuth nitrate solution.

[0036] (4) The solution prepared in step (2) was slowly added dropwise to step (3) under magnetic stirring conditions, after the dropwise addition was completed and vigorously st...

Embodiment 3

[0039] The attapulgite / carbon precursor material was impregnated with bismuth nitrate and potassium bromide respectively to explore the effect of BiOBr crystals on the attapulgite / carbon precursor material in situ growth.

[0040] (1) Take 3g of attapulgite and 1mL of aniline and evenly disperse in 50mL of aqueous solution (solid-to-liquid ratio of attapulgite to aniline (g / mL) = 3:1), transfer the system to 0°C and stir for 12h, in situ polymerization Attapulgite / polyaniline composite material was obtained. Further calcined carbonization (900℃ / 2h, N 2 ), the nitrogen-doped attapulgite / carbon precursor material can be obtained.

[0041] (2) Weigh 427 mg of nitrogen-doped attapulgite / carbon prepared in step (1) and 0.97 g of bismuth nitrate pentahydrate, disperse in 30 mL of glycerin and sonicate for 30 min to obtain a uniform suspension.

[0042] (3) Weigh 0.238 g of potassium bromide in 30 mL of aqueous solution and magnetically stir for 0.5 h to dissolve it to prepare a pota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com