Three-adsorber air separation and purification device and method for double-coupled thermochemical heat storage system

A technology of heat storage system and purification device, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of difficult utilization of cold blowing nitrogen, difficulty in recycling, high temperature of dirty nitrogen, etc. Thermal effect, reduction of heat storage cost, effect of stable thermal output temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below with specific embodiments in conjunction with the accompanying drawings.

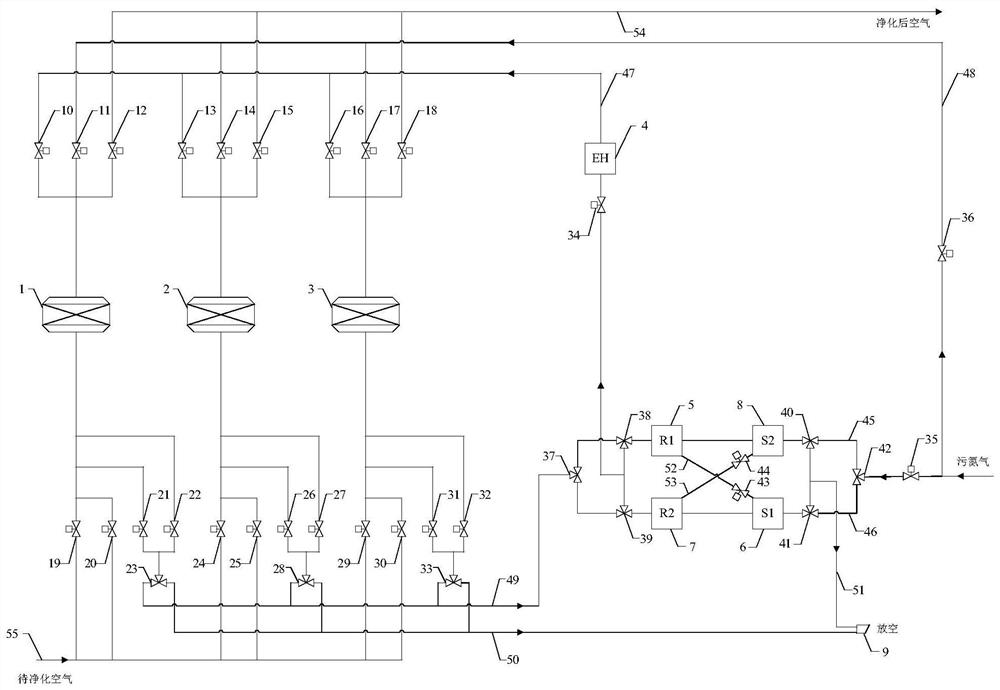

[0039] see figure 1 , a three-adsorber air separation purification device based on a dual-coupled thermochemical heat storage system, which includes a first molecular sieve adsorber 1, a second molecular sieve adsorber 2, a third molecular sieve adsorber 3, an electric heater 4, a first Thermochemical reactor 5, first liquid reservoir 6, second thermochemical reactor 7, second liquid reservoir 8, first branch 45 of waste heat recovery channel of dirty nitrogen gas, second branch 46 of waste heat recovery channel of dirty nitrogen gas, Polluted nitrogen heating channel 47, polluted nitrogen cooling blowing channel 48, polluted nitrogen waste heat recovery channel 49, polluted nitrogen venting channel 50, polluted nitrogen venting channel first branch 51, first refrigerant channel 52, second refrigerant channel 53, Air outlet channel 54 , air i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com