Automatic sugar-free biscuit forming machine controlled by PLC

An automatic forming machine and biscuit technology, applied in the direction of electrical program control, program control in sequence/logic controller, dough extruder, etc., can solve the problems affecting the production speed of biscuits, slow forming speed, low efficiency, etc., to achieve Save labor, improve production efficiency, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

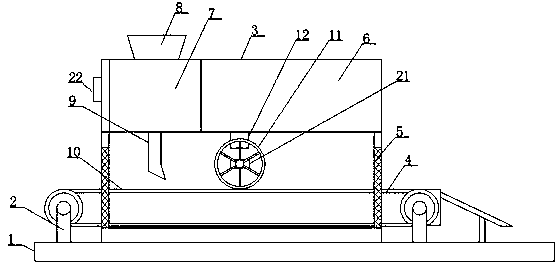

[0024] Such as Figure 1-2 As shown, the PLC-controlled sugar-free biscuit automatic forming machine according to the embodiment of the present invention includes a base plate 1 and columns 2 symmetrically arranged at the top of the base plate 1, and the top of the base plate 1 and between the columns 2 are provided with A housing 3, a conveyor belt 4 passing through the housing 3 is provided between the columns 2, and an entrance and exit 5 matching the conveyor belt 4 are provided on both sides of the housing 3. The top is provided with a compartment 6, and one side of the compartment 6 is provided with a storage chamber 7, and the top of the bottom plate 1 is provided with a feed funnel 8 connected to the storage chamber 7, and the compartment The bottom end of 6 is provided with and is positioned at the bottom of described storage chamber 7 and is provided with guide tube 9, and described conveyer belt 4 is provided with the feed channel 10 that matches with described guid...

Embodiment 2

[0026] Such as Figure 1-2 As shown, the top of the bottom plate 1 and one side of the conveyor belt 4 are provided with a deflector arranged obliquely, and there is a gap between the deflector and the conveyor belt 4. It is not difficult to see from the above design that The design of the deflector makes it convenient to quickly transport the formed biscuits to the next process and improve its efficiency.

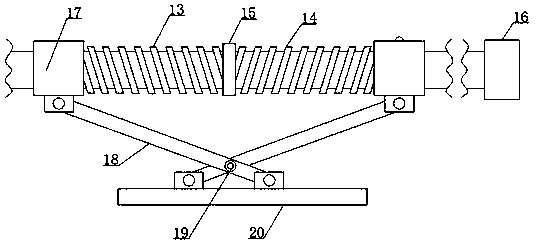

[0027] The movable rod 18 is respectively connected with the slider 17 and the backing plate 20 through a bearing, and the slider 17 is provided with internal threads matched with the first screw rod 13 and the second screw rod 14 Groove, it is not difficult to find out from above-mentioned design, and the design of bearing is convenient for movable rod 18 to rotate, and improves the flexibility of its movable rod 18.

[0028] The threads of the first screw rod 13 and the second screw rod 14 have opposite thread directions, and the sliders 17 are arranged on the first scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com