Wheat straw pulverizer and feed processing method

A technology of wheat straw and pulverizer, which is applied in the preservation method, application, and animal feed of animal feed raw materials, which can solve the problems of excessive labor and low efficiency, and achieve the effect of improving processing efficiency and reducing the use of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

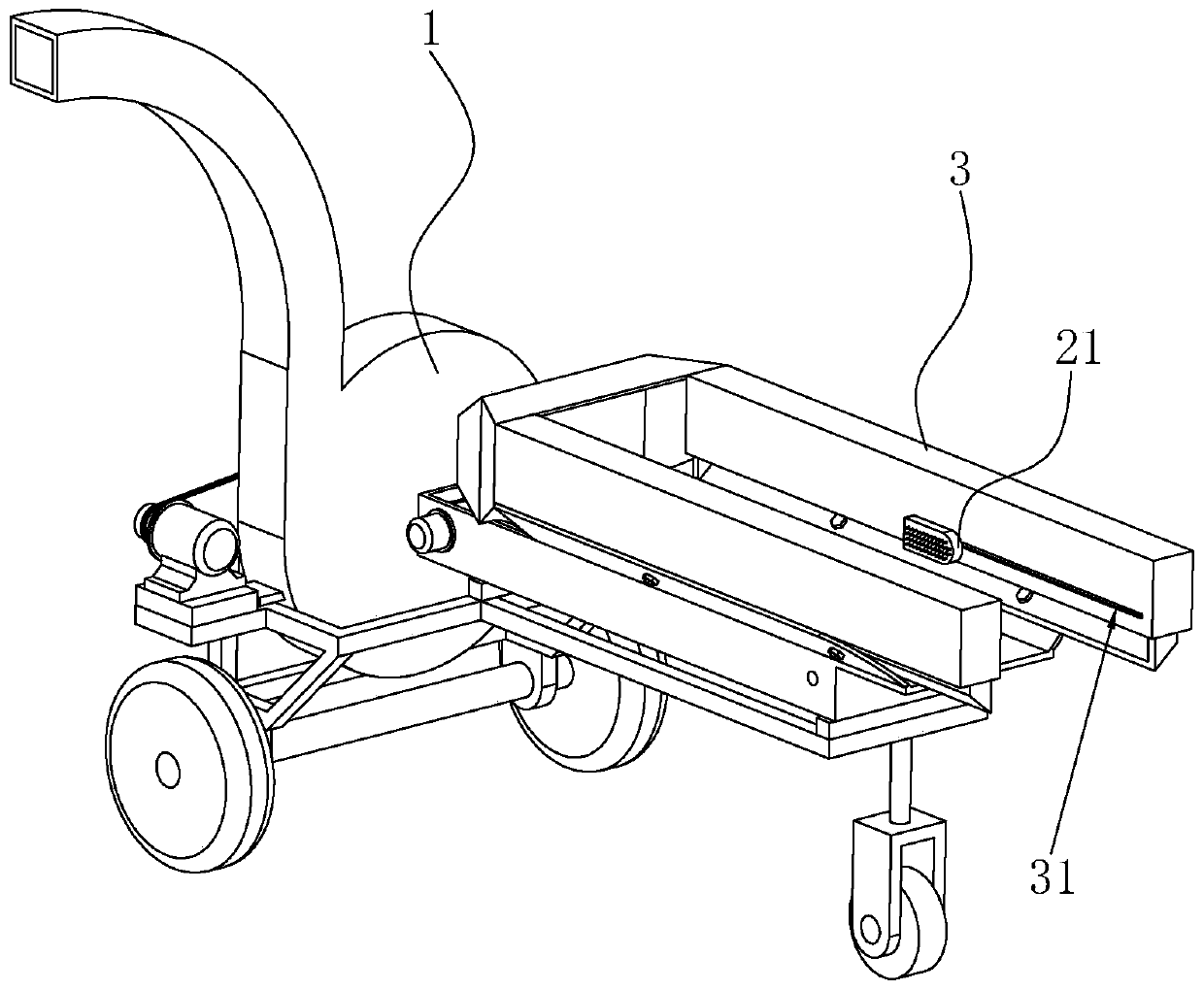

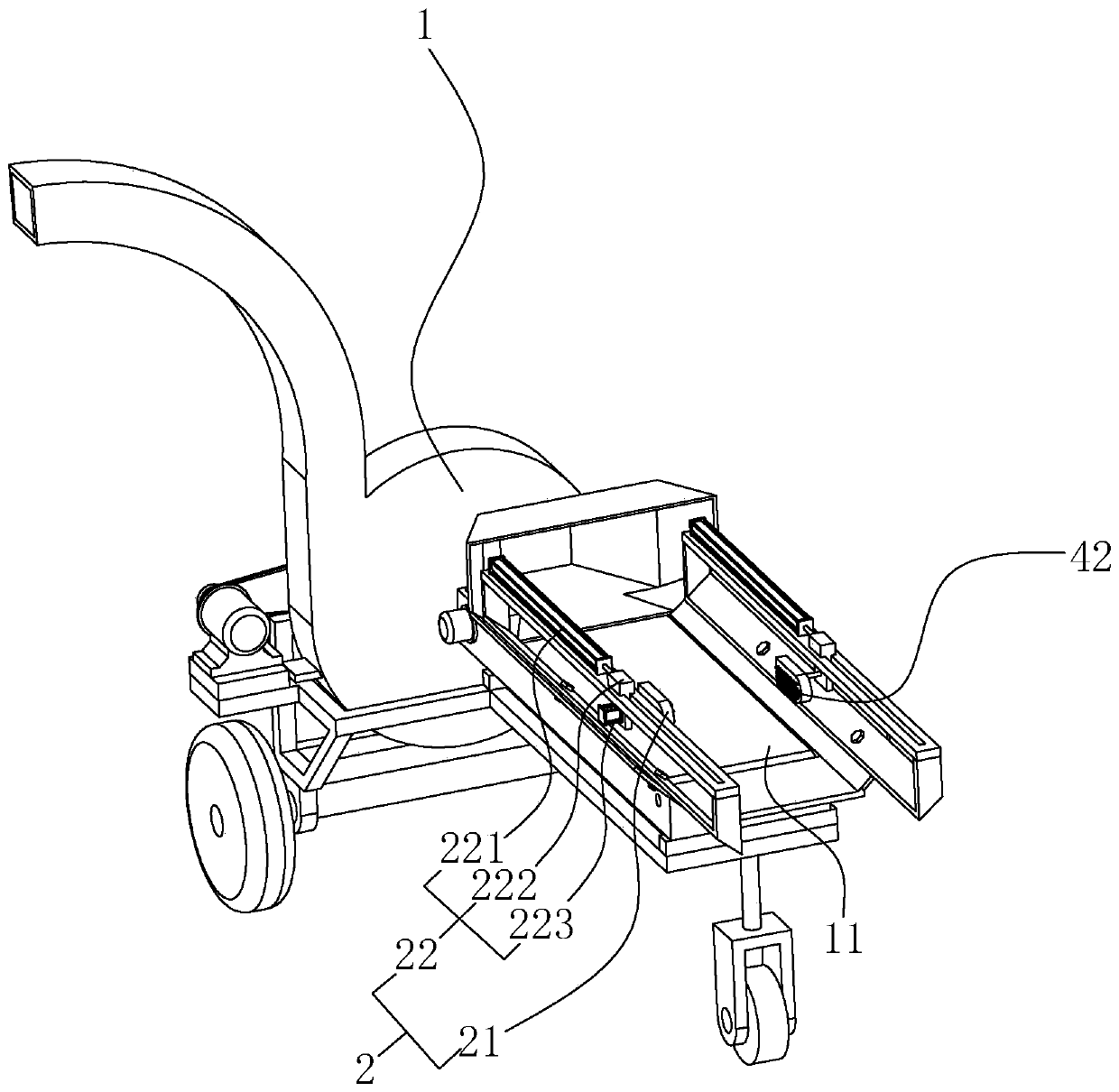

[0043]combine figure 1 and figure 2 , a wheat straw pulverizer, comprising a pulverizer body 1, the pulverizer body 1 is provided with a conveyor belt 11 for feeding materials, an automatic feeding device 2 is provided above the conveyor belt 11, the automatic feeding device 2 clamps the wheat straw and The wheat straw is placed on the conveyor belt 11. Compared with the manual feeding method in the prior art, this embodiment achieves the effect of reducing the use of labor and improving the processing efficiency.

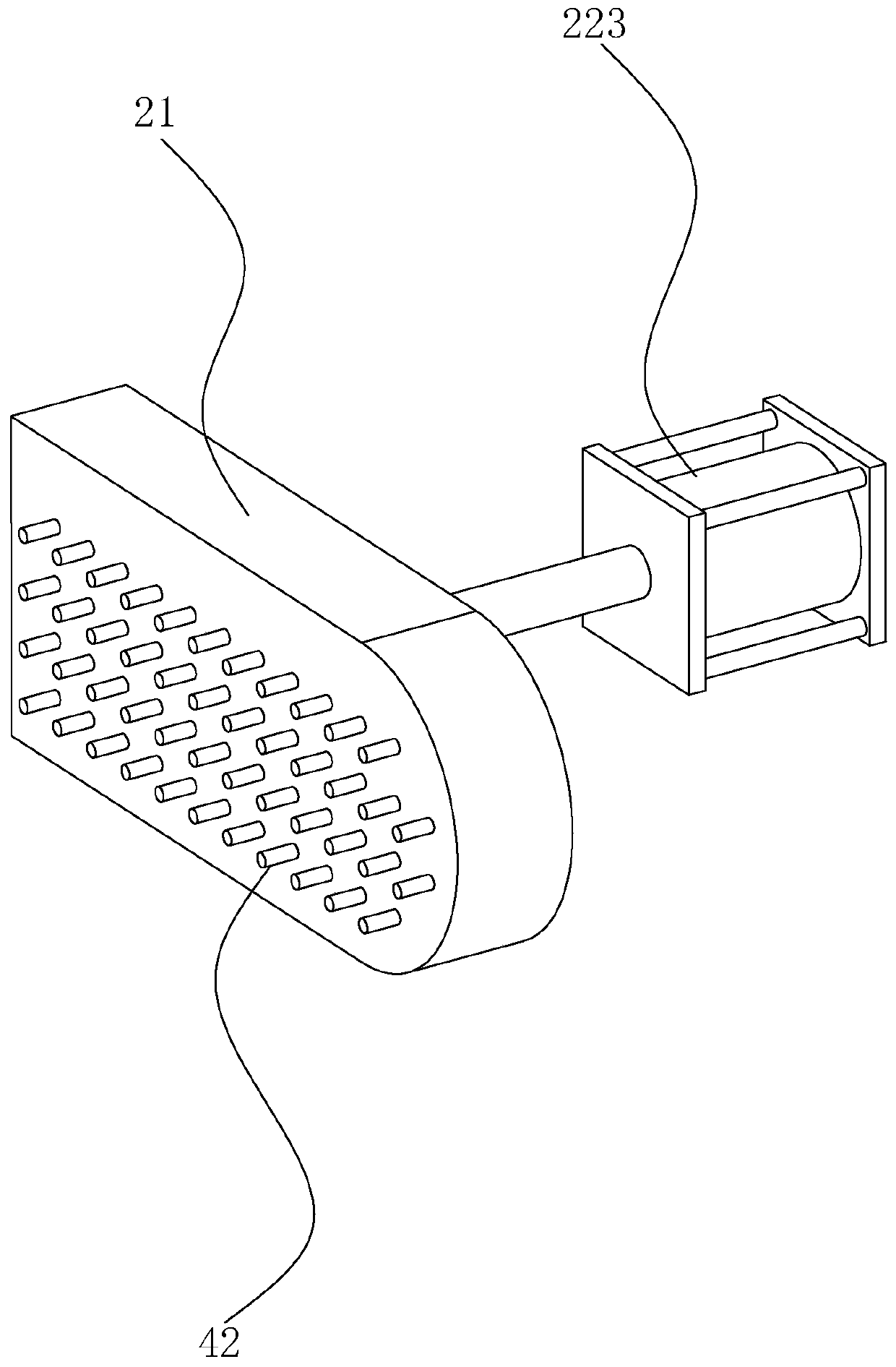

[0044] combine figure 2 and image 3 The automatic feeding device 2 includes two opposite clamping plates 21 and a driving device 22 that drives the clamping plate 21 to move. The driving device 22 includes a moving cylinder 221, a connecting block 222 and a positioning cylinder 223. The moving cylinder 221 is parallel to the conveyor belt. The transmission direction of 11 is set, the connecting block 222 is fixedly connected with the piston rod of the moving ...

Embodiment 2

[0050] A method for processing wheat straw for feeding, which is characterized in that it comprises the following steps: rubbing and pulverizing wheat straw, ammoniating treatment, centrifuging to remove water, fermenting, packing,

[0051] a, using the pulverizer body described in any one of claims 1-9 to pulverize the wheat straw for 2-4 hours;

[0052] b. Move the product obtained in step a to the reaction tank, add ammoniating agent, and carry out ammoniation treatment for 2-4 hours while stirring;

[0053] c, the product obtained in step b is moved into a centrifuge, and the centrifuge is rotated for 0.5 hour to carry out dehydration treatment;

[0054] d, adding fermentation bacteria to the product obtained in step c and stirring;

[0055] e, packing the product obtained in step d.

[0056] The wheat straw is placed on one side of the grinder body, and the material is automatically loaded through the grinder body to improve the processing efficiency of the wheat straw....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com