Double-frequency FSS with close interval frequency response characteristic and unit structure thereof

A technology of interval frequency and response characteristics, applied in the field of dual-frequency FSS and its unit structure, can solve the problems of large resonance response interval, failure to meet FSS requirements, and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

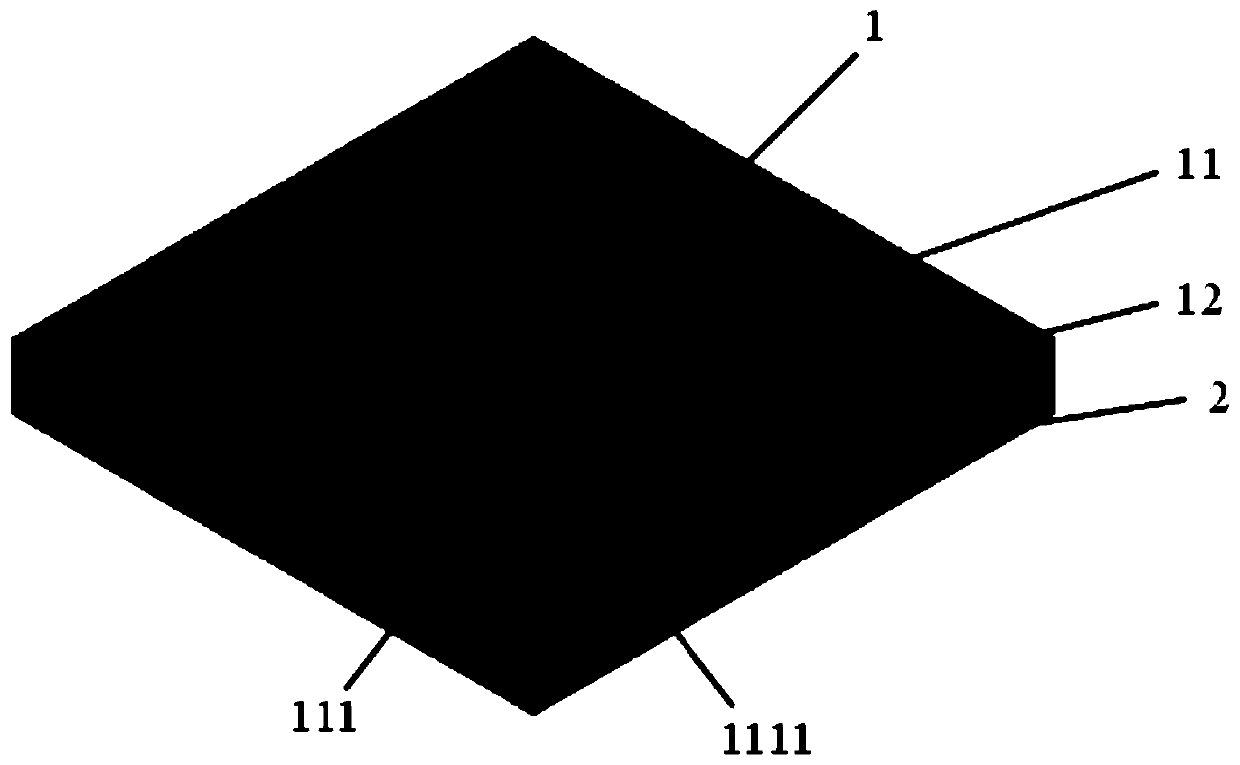

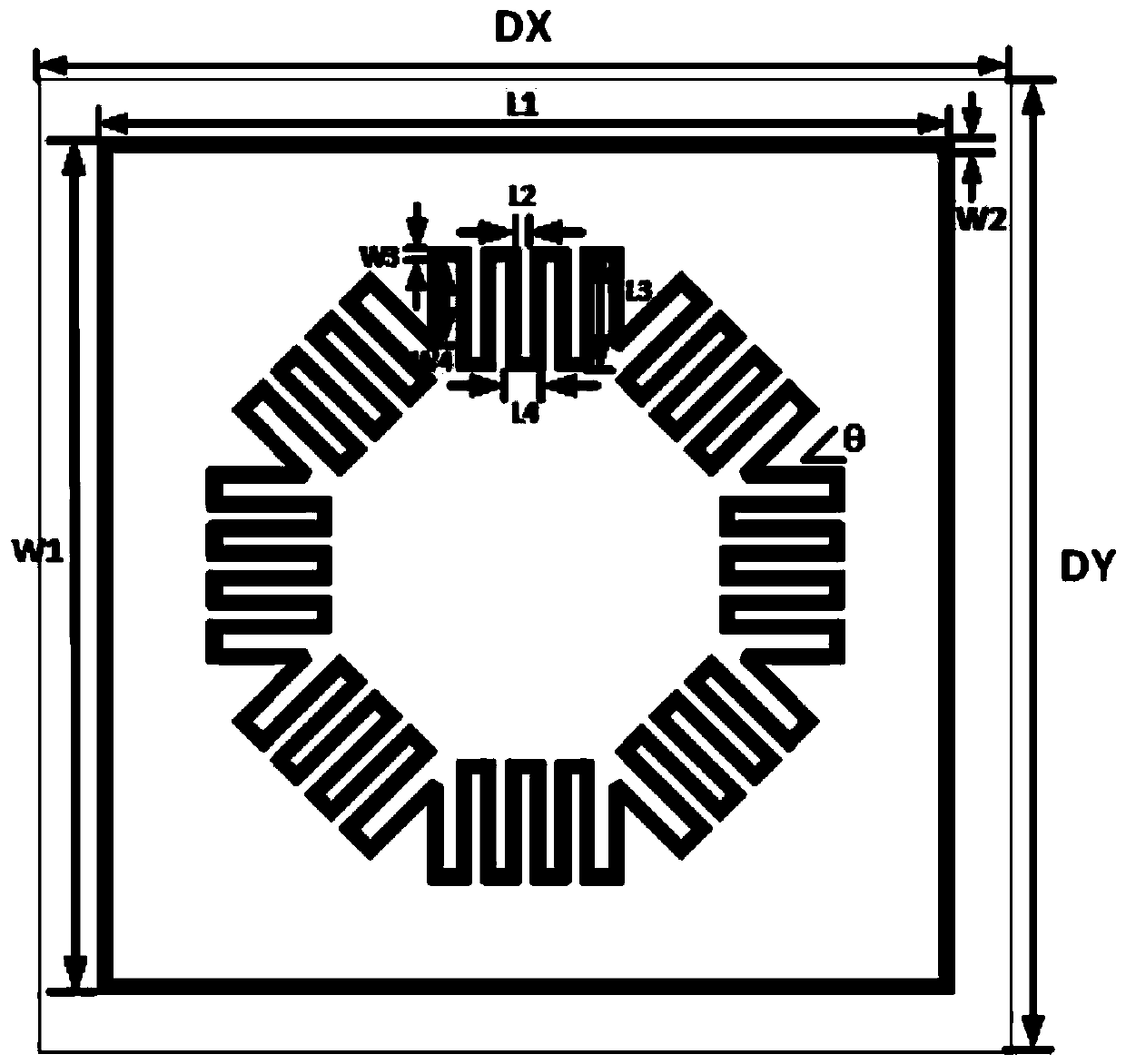

[0038] See figure 1 and figure 2 , figure 1 It is a perspective view of a dual-frequency FFS unit structure with closely spaced frequency response characteristics provided by an embodiment of the present invention; figure 2 It is a side view of a dual-frequency FFS unit structure with closely spaced frequency response characteristics provided by an embodiment of the present invention. The dual-frequency FFS unit structure includes a metal layer 1 and a dielectric substrate 2 , and the metal layer 1 is disposed on the dielectric substrate 2 . In this embodiment, the upper surface of the dielectric substrate 2 has a square structure with a size of 8mm*8mm. In addition, the thickness of the metal layer 1 is in the range of 0.017mm-0.035mm, and the thickness of the dielectric substrate 2 is 1mm. Compared with the existing FFS unit, the size of the dual-frequency FFS unit structure in this embodiment is very small, meeting the current trend of pursuing miniaturization of devi...

Embodiment 2

[0047] On the basis of the above embodiments, this embodiment provides a dual-frequency FFS with closely spaced frequency response characteristics. See Figure 4 , Figure 4 It is a perspective view of a dual-frequency FFS with closely spaced frequency response characteristics provided by an embodiment of the present invention. The dual-frequency FFS includes M×N periodically arranged dual-frequency FFS unit structures as described in Embodiment 1, wherein M and N are integers greater than or equal to 1. In this embodiment, the dual-frequency FFS includes 6×6 unit structures. In other embodiments, the dual-frequency FFS may also include other numbers of unit structures, such as 10×10, 20×20, 40×40 ,even more.

[0048] As mentioned above, the dual-frequency FFS is formed by the periodic arrangement of the dual-frequency FFS unit structure described in the first embodiment, that is, the adjacent dielectric substrates 2 are closely attached. Since the distance between the fou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com