Vertical method fabric capillary effect evaluation device

A capillary effect and evaluation device technology, applied in the direction of surface/boundary effects, measurement devices, analysis materials, etc., to achieve accurate evaluation and enrich the effect of evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

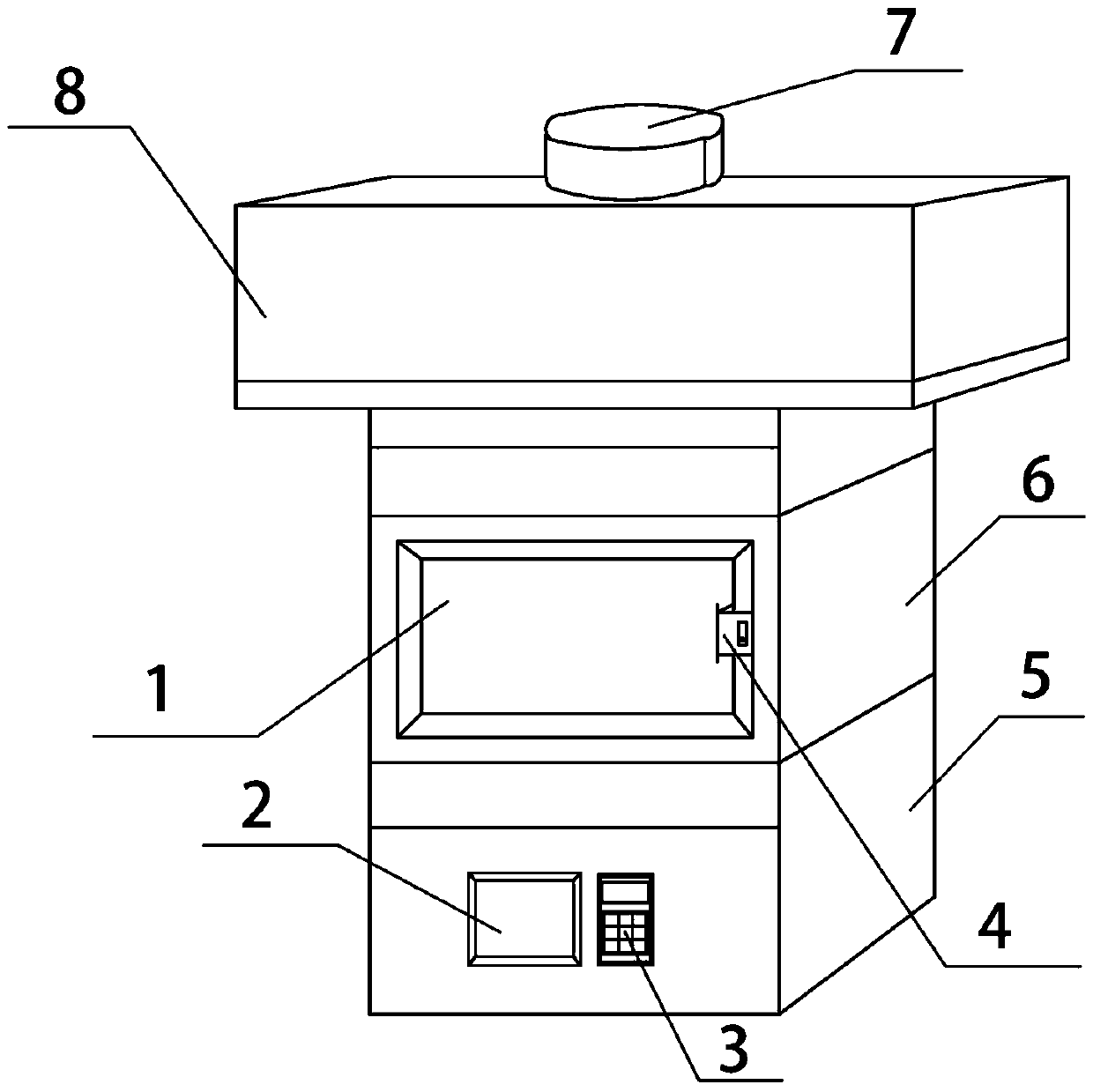

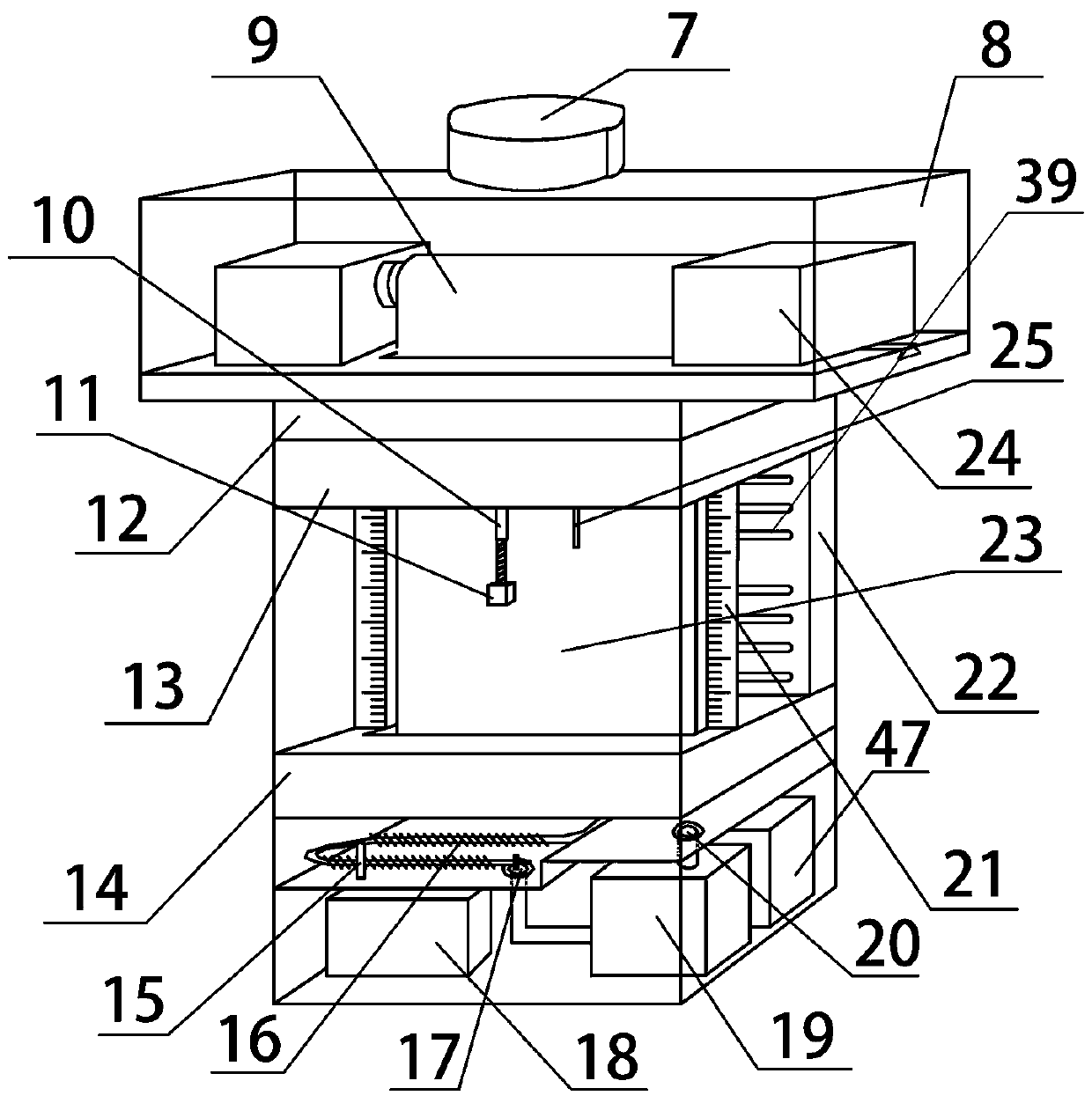

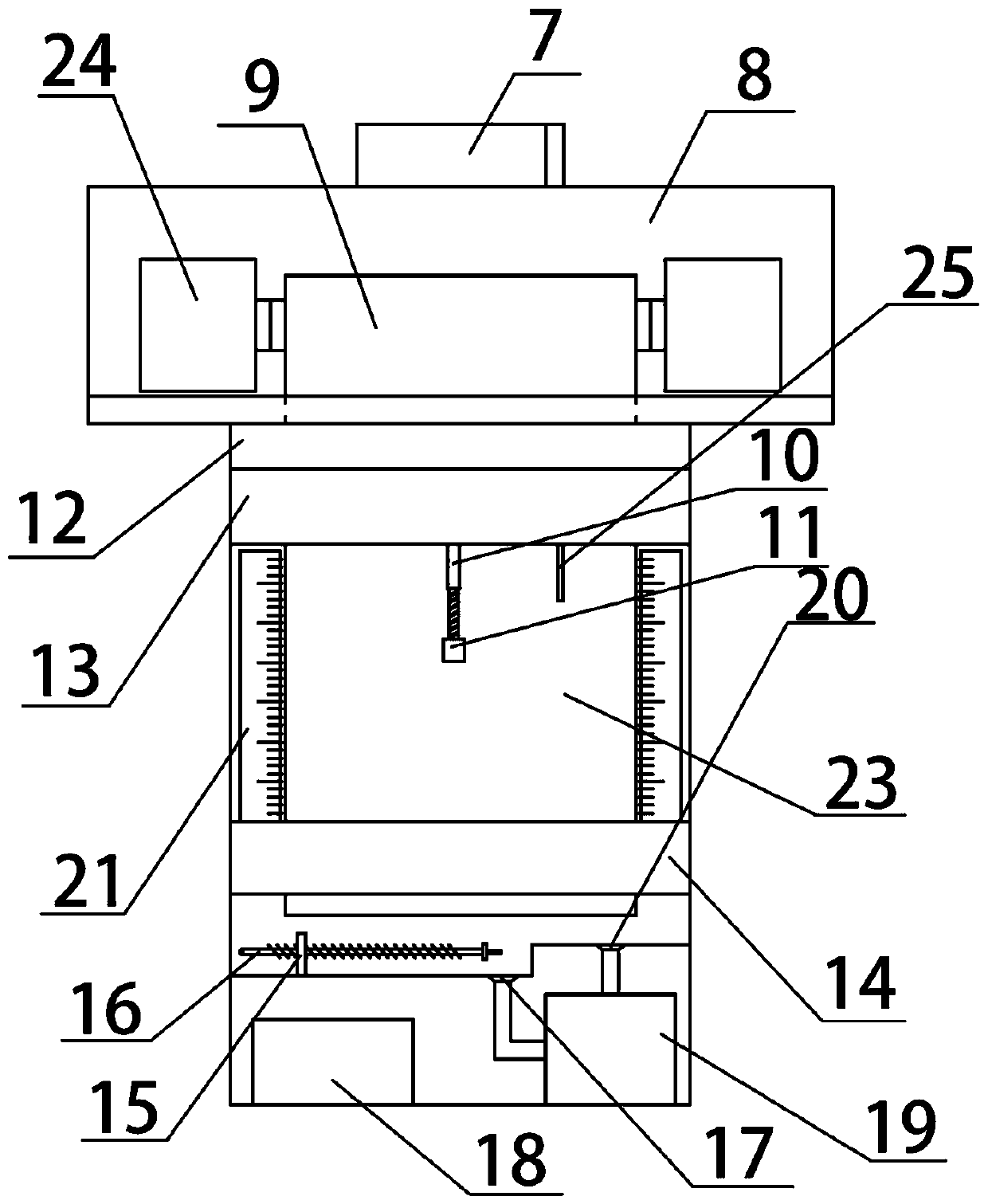

[0035] see figure 1 , a vertical fabric capillary effect evaluation device, the device uses the principle of capillary effect, image acquisition technology and digital image processing technology to test the wicking and water-conducting properties of fabrics. The device consists of a capillary effect test chamber 6, a closed chamber door 1, a door switch 4, a device function control box 5, an input keyboard 3, a data display screen 2, a cloth sample chamber 8 and a powerful exhaust fan 7. The test chamber 6 is arranged above the device function control box 5 , and the cloth roll sample chamber 8 is arranged above the capillary effect test chamber 6 . The powerful exhaust fan 7 is installed on the cloth roll sample chamber 8, the data display screen 2 and the input keyboard 3 are installed on the device function control box 5, and the airtight chamber door 1 is installed on the capillary effect test chamber 6 through the chamber door switch 4. The data display screen 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com