Three-dimensional MEMS oceanic turbulence sensor

A sensor and marine technology, applied in the field of sensors, can solve the problems of decreased sensitivity, decreased hotline response speed, decreased resolution, etc., and achieves good results and accurate vector test results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

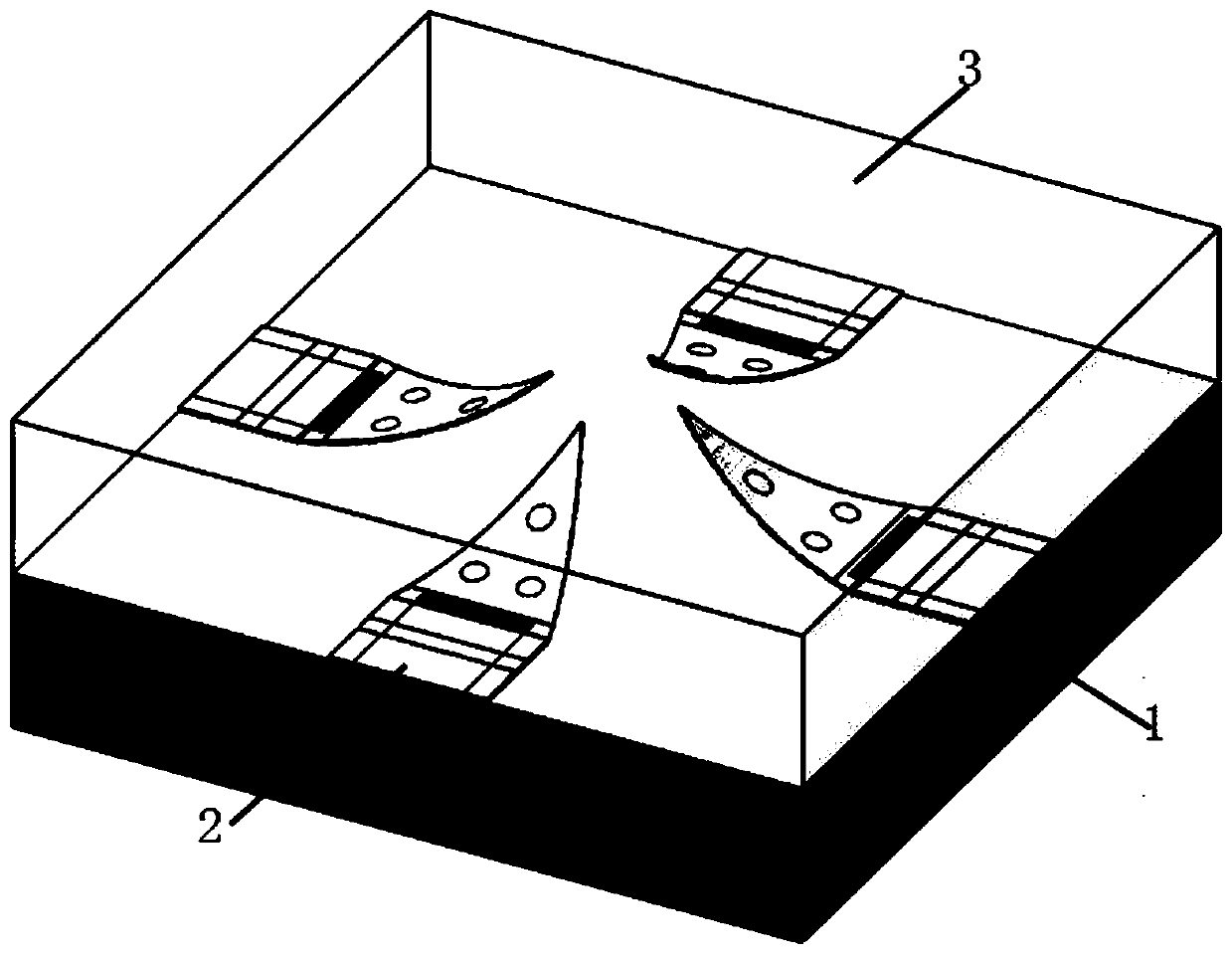

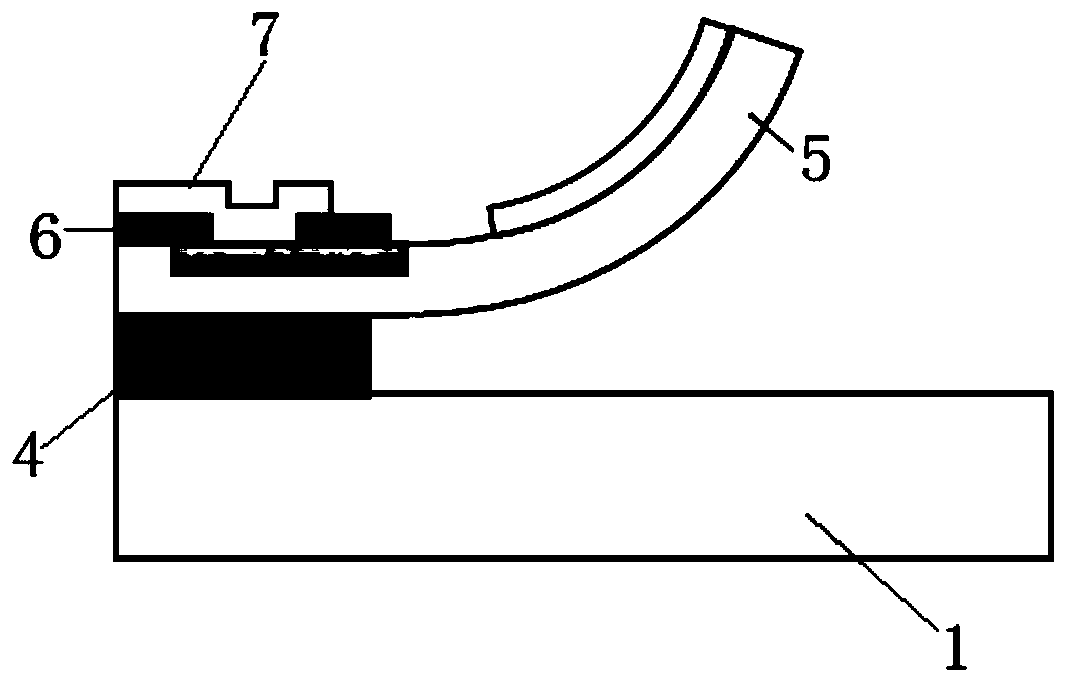

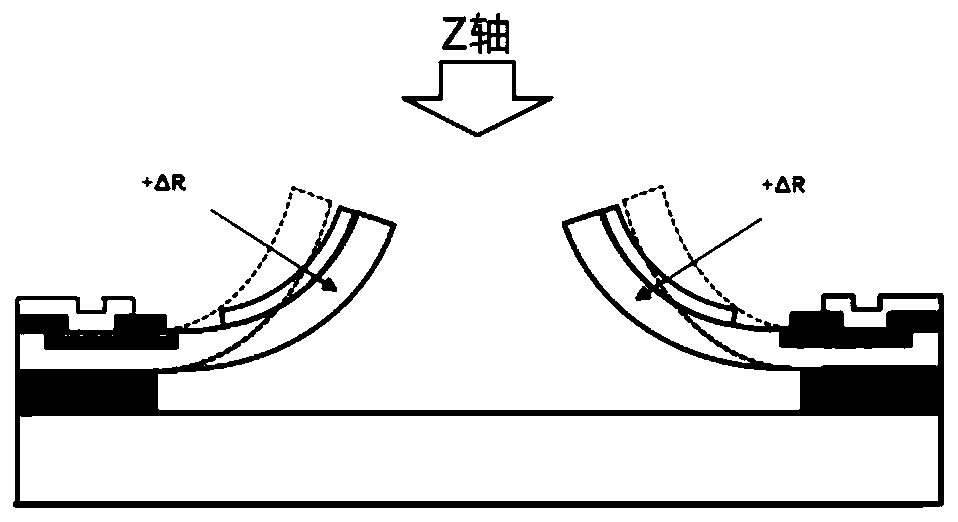

[0031] combine figure 1 with figure 2 , a three-dimensional MEMS ocean turbulence sensor, the final structure of the sensor is a cuboid shape with a length and width of 1mm and a thickness of about 0.4mm, including a sensing unit, which includes a base structure 1, the base structure 1 is a thin silicon-based material with a thickness of 0.2mm, the length and width are 1mm; the base structure 1 is provided with four micro-cantilever beams 2 arranged in a cross shape, and the lower end surface of the micro-cantilever beams 2 passes through the connecting layer 4 (such as SiO 2 Layer) connected to the base structure, each micro-cantilever beam is curled toward one end of the cross-shaped center, and the base structure 1 and the micro-cantilever beam 2 are covered with an elastic coating body 3; each micro-cantilever beam 1 includes a bottom-up Si thin film layer 5, SiN thin film layer 6 and Cr thin film layer 7 are arranged on it, and piezoresistors are arranged on the microca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com