A kind of nano tanning agent based on structural memory effect and its preparation method and application

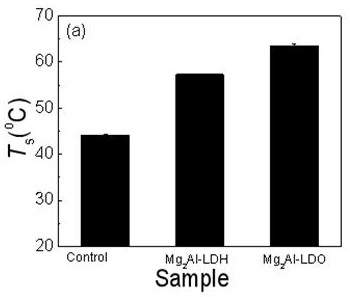

A structure memory and nanotechnology, applied in the field of leather tanning agents, can solve the problems of wastewater pollution, environmental hazards of chromium-containing waste, etc., and achieve the effects of improving uniform dispersion, enhancing adsorption performance, and increasing shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

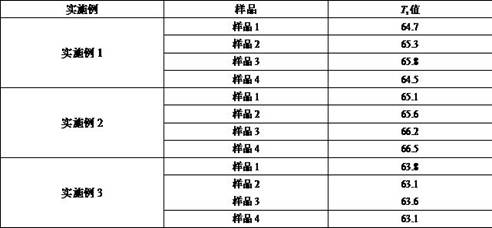

Embodiment 1

[0021] (1) Preparation of nano-tanning agent: Dissolve magnesium nitrate and aluminum nitrate in 50ml water to prepare metal salt solution A, and dissolve sodium carbonate in 100 ml water to prepare 0.875 mol / L according to the molar ratio of magnesium to aluminum elements of 2:1 Sodium carbonate solution B; then add solution A dropwise into solution B, and at the same time adjust the pH value to 12 with 2 mol / L sodium hydroxide solution, nucleate and crystallize at a temperature of 75°C for 10 hours, centrifuge, freeze-dry, and then The obtained product was calcined at 450°C for 4 hours to obtain the nano-tanning agent.

[0022] (2) Tanning: at room temperature, add water and softened skin with a mass ratio of 1:1 into the drum, add 8% sodium chloride with tare weight, and turn for 30 minutes; add nano-tanning agent with 3% tare weight , adjust the pH value of the bath solution to 3.0 with 2% formic acid solution, and then rotate for 2 hours; add saturated sodium acetate solu...

Embodiment 2

[0024] (1) Preparation of nano-tanning agent: Dissolve magnesium nitrate and aluminum nitrate in 50ml water to prepare metal salt solution A, and dissolve sodium carbonate in 100 ml water to prepare 0.875 mol / L according to the molar ratio of magnesium to aluminum elements of 2:1 Sodium carbonate solution B; then add solution A dropwise into solution B, and at the same time adjust the pH value to 12 with 2 mol / L sodium hydroxide solution, nucleate and crystallize at a temperature of 75°C for 10 hours, centrifuge, freeze-dry, and then The obtained product was calcined at 450°C for 4 hours to obtain the nano-tanning agent.

[0025] (2) Tanning: at room temperature, add water and softened skin with a mass ratio of 1:1 into the drum, add 8% sodium chloride with tare weight, and turn for 30 minutes; add nano-tanning agent with 3% tare weight , adjust the pH value of the bath solution to 3.0 with 2% formic acid solution, and then rotate for 2 hours; add saturated sodium acetate solu...

Embodiment 3

[0027] (1) Preparation of nano-tanning agent: Dissolve magnesium nitrate and aluminum nitrate in 50ml water to prepare metal salt solution A, and dissolve sodium carbonate in 100 ml water to prepare 0.875 mol / L according to the molar ratio of magnesium to aluminum elements of 2:1 Sodium carbonate solution B; then add solution A dropwise into solution B, and at the same time adjust the pH value to 12 with 2 mol / L sodium hydroxide solution, nucleate and crystallize at a temperature of 75°C for 10 hours, centrifuge, freeze-dry, and then The obtained product was calcined at 450°C for 4 hours to obtain the nano-tanning agent.

[0028] (2) Tanning: at room temperature, add water and softened skin with a mass ratio of 1:1 into the drum, add 8% sodium chloride with tare weight, and turn for 30 minutes; add nano-tanning agent with 5% tare weight , adjust the pH value of the bath solution to 3.0 with 2% formic acid solution, and then rotate for 2 hours; add saturated sodium acetate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com