Pay-off equipment for power cable laying

A technology of power cables and cables, applied in the field of pay-off equipment, can solve the problems of low pay-off speed, slow pay-off speed, and inconvenient pay-off frame, etc., and achieve the effect of smooth pay-off, high efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

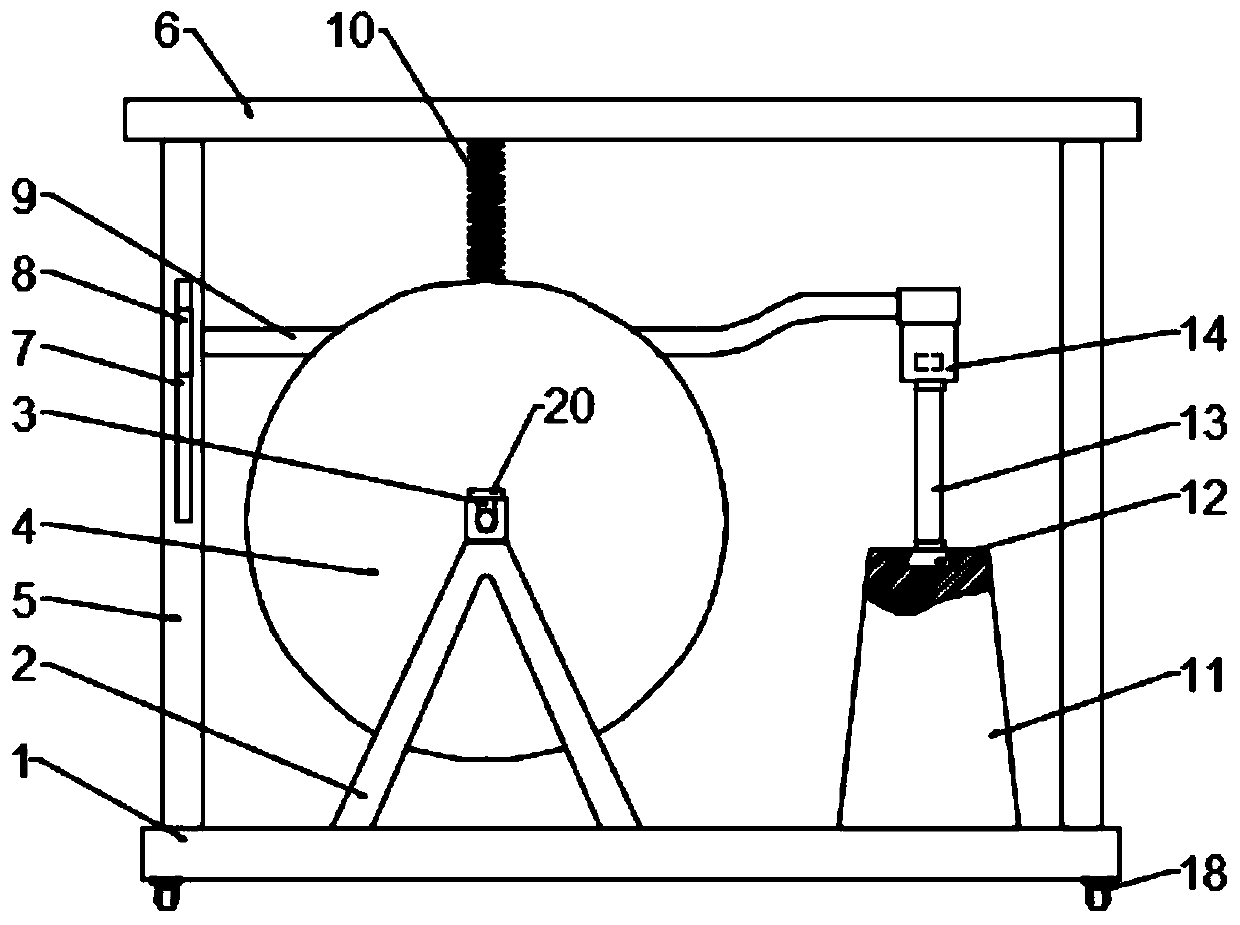

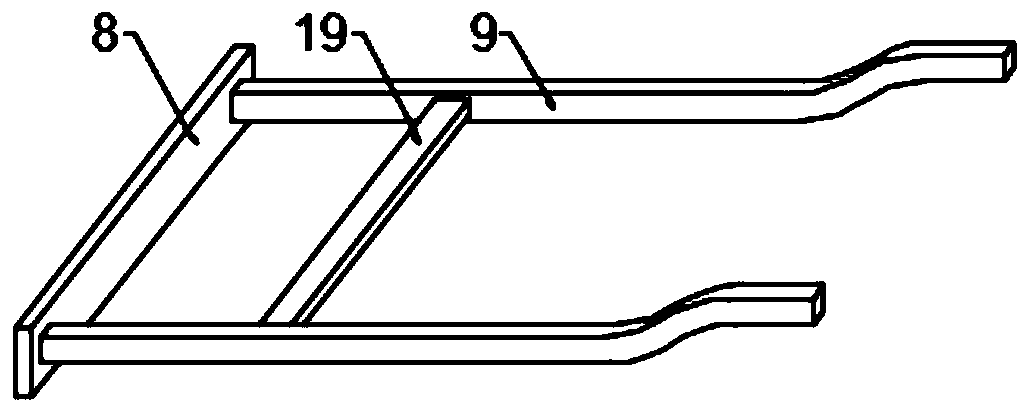

[0022] Example 1: Please refer to Figure 1-3 , a pay-off device for laying electric cables, comprising a fixed bottom plate 1, a bobbin connecting bracket 2 is fixedly connected to the upper left side of the fixed bottom plate 1, a groove 3 is opened on the top of the bobbin connecting bracket 2, and a cable bobbin is placed on the inner side of the groove 3 to rotate 4. The left and right sides of the fixed bottom plate 1 are fixedly connected with uprights 5 symmetrically, the top of the uprights 5 is fixedly connected with the upper beam 6, and the left side upright 5 is provided with a limit chute 7, and the inside of the limit chute 7 is slidingly connected with a limit Skateboard 8, the right side of limit slide plate 8 is symmetrically fixedly connected with adjusting rod 9 front and rear, and adjusting rod 9 cooperates with the cable on the cable spool 4, and is fixedly connected with first spring 10 on the upper beam 6, and the lower end of first spring 10 is connecte...

Embodiment 2

[0029] Example 2: Please refer to Figure 1-3 , in this embodiment, it includes a fixed bottom plate 1, and the upper left side of the fixed bottom plate 1 is fixedly connected with a bobbin connecting bracket 2, and the top of the bobbin connecting bracket 2 is provided with a groove 3, and the inner side of the groove 3 is rotated to place a cable bobbin 4. The top of the slot 3 is movably connected with buckles 20, and the buckles 20 are used for clamping the cable spool 4 to prevent the cable spool 4 from breaking away from the groove 3 during the unwinding process. The top of the fixed base plate 1 is symmetrically fixedly connected with uprights 5 and uprights. 5. The upper beam 6 is fixedly connected to the top, and the limit chute 7 is provided on the left column 5, and the limit slide 8 is slidably connected to the limit slide 8, and the right side of the limit slide 8 is symmetrically fixedly connected with an adjustment rod 9 , the adjusting rod 9 cooperates with th...

Embodiment 3

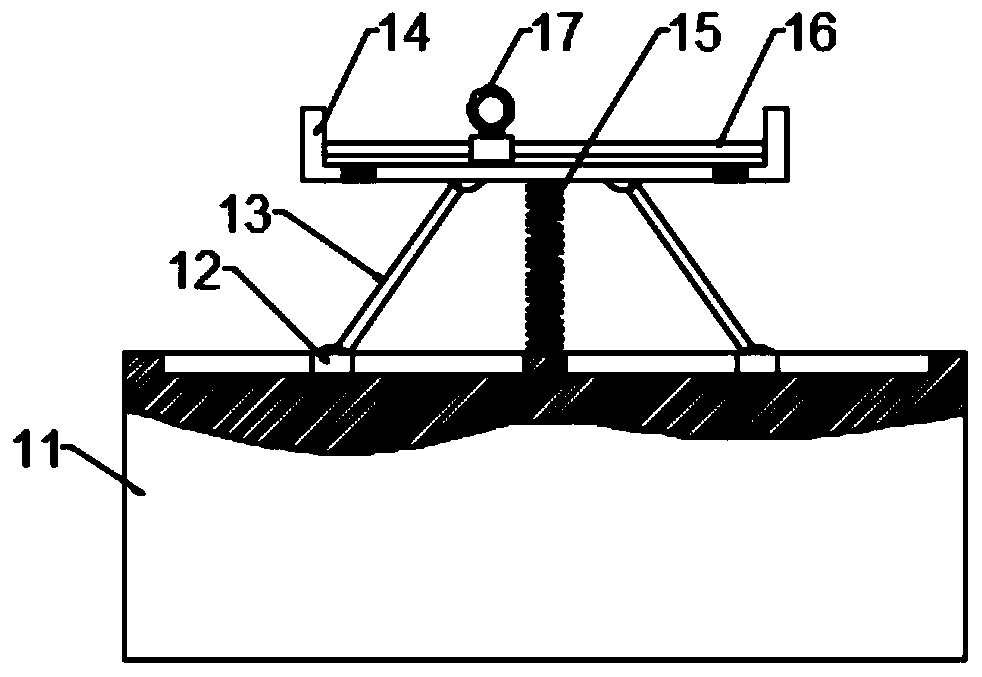

[0033] Example 3: Please refer to Figure 4 , in the present embodiment, it includes a fixed bottom plate 1, the upper left side of the fixed bottom plate 1 is fixedly connected with a bobbin connection bracket 2, the top of the bobbin connection bracket 2 is provided with a groove 3, and the inner side of the groove 3 is rotated to place a cable bobbin 4, the fixed The left and right sides of the bottom plate 1 are fixedly connected with uprights 5 symmetrically, the top of the uprights 5 is fixedly connected with an upper beam 6, and a limit chute 7 is provided on the left side upright 5, and a limit slide 8 is slidably connected in the limit chute 7, and the limit The right side of the slide plate 8 is symmetrically fixedly connected with an adjusting rod 9 front and rear, the adjusting rod 9 cooperates with the cable on the cable spool 4, the upper beam 6 is fixedly connected with a first spring 10, and the lower end of the first spring 10 is fixedly connected with the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com