Railway brake capable of recycling friction heat energy

A friction heat energy and brake technology, used in automatic brakes, household heating, railway car body parts, etc., can solve the problems of poor braking effect, easily damaged brakes, waste of heat energy, etc., and achieve good braking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

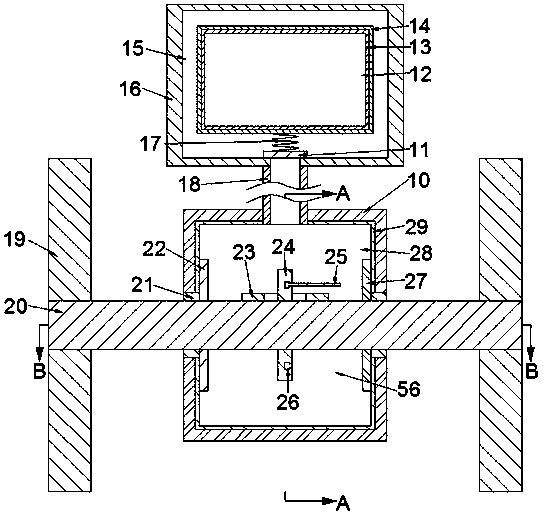

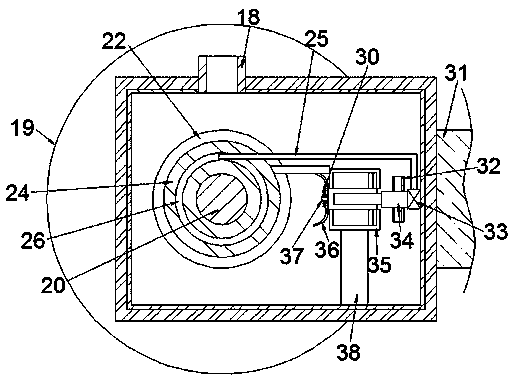

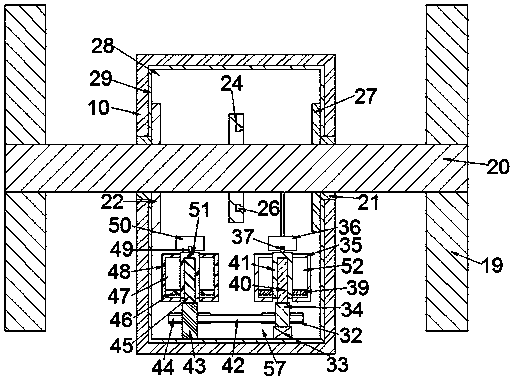

[0018] Such as Figure 1-4 As shown, a railway brake that can recycle frictional heat energy includes a working box 10 and a fixed block 31 fixedly connected to the front end of the working box 10, the fixed block 31 is fixedly connected to the car body, and the working box The upper side of 10 is provided with a heating box 16, the heating box 16 is provided with an air chamber 15 which can lead into heat-sensitive gas, the air chamber 15 is provided with a water tank 13, and the outer wall of the water tank 13 is fixed with a good heat conduction A heat conduction plate 14, the heat conduction plate 14 is provided with a water chamber 12, the water chamber 12 is filled with water to be heated, and the work box 10 is provided with a friction chamber 28, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com