Round tube outer wall crawling robot

A technology of crawling robots and round pipes, applied in the field of robotics, can solve problems such as difficult maintenance, unmanned development, and easy jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

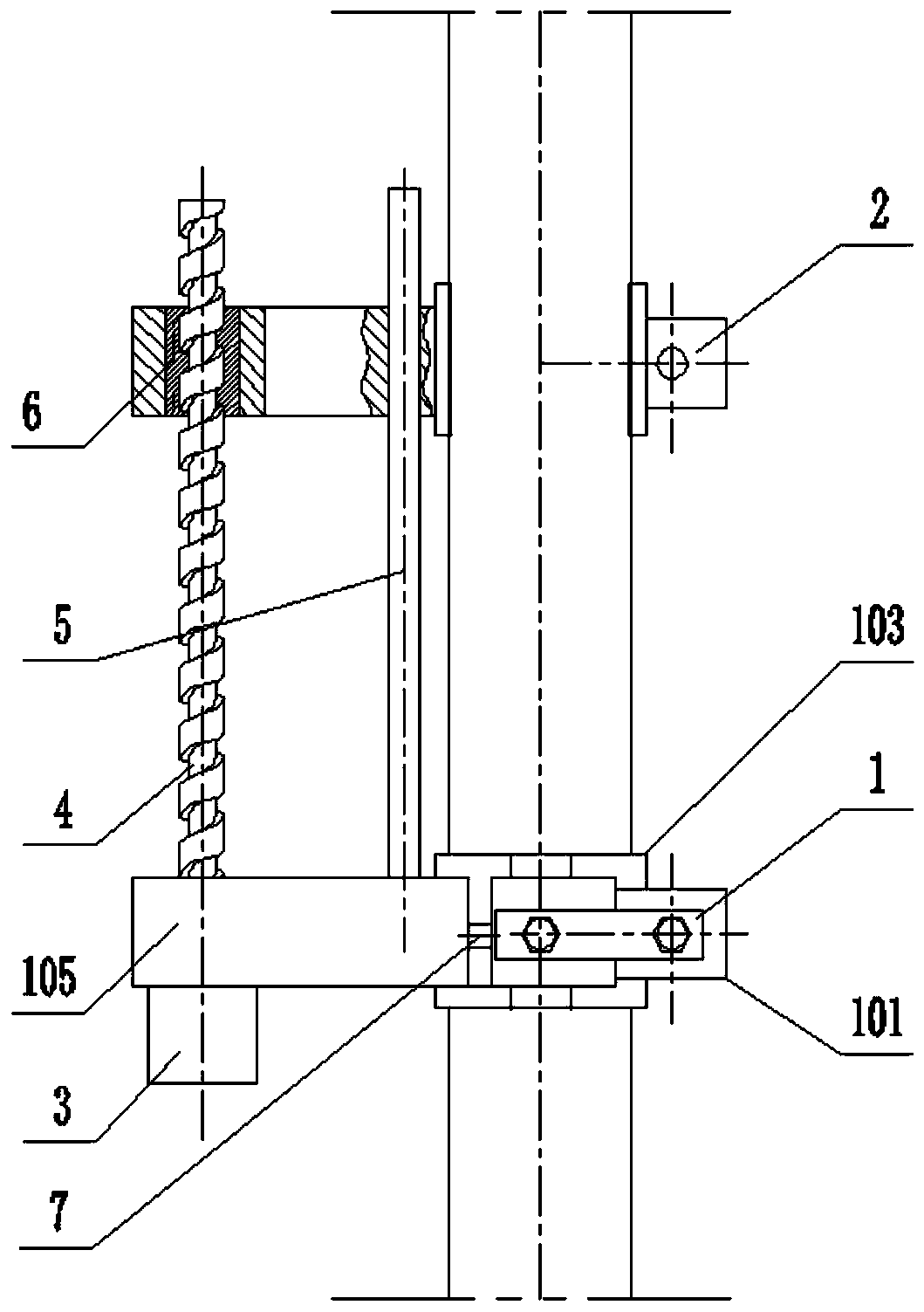

[0024] The present invention is a circular tube outer wall crawling robot, such as figure 1 As shown, it includes two front holding devices 2 and rear holding devices 1 arranged side by side. The rear holding device 1 and the front holding device 2 are jointly hinged with a crawling device, and the crawling device includes a rear holding device fixed on the 1 Servomotor 3, servomotor 3 is connected with screw rod 4, is embedded with nut 6 in the position corresponding to screw rod 4 on the front holding device 2, and screw rod 4 stretches in the nut 6.

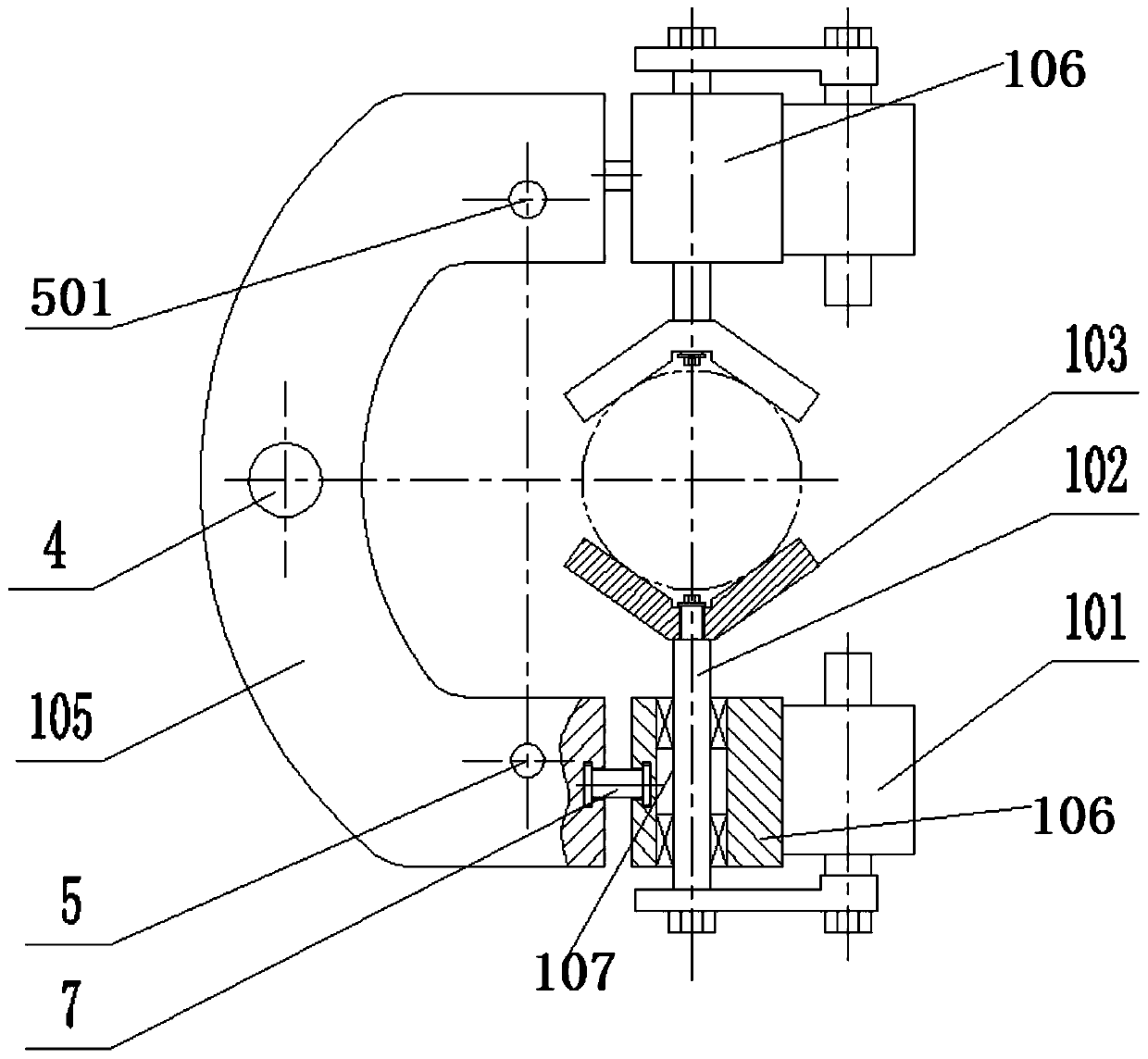

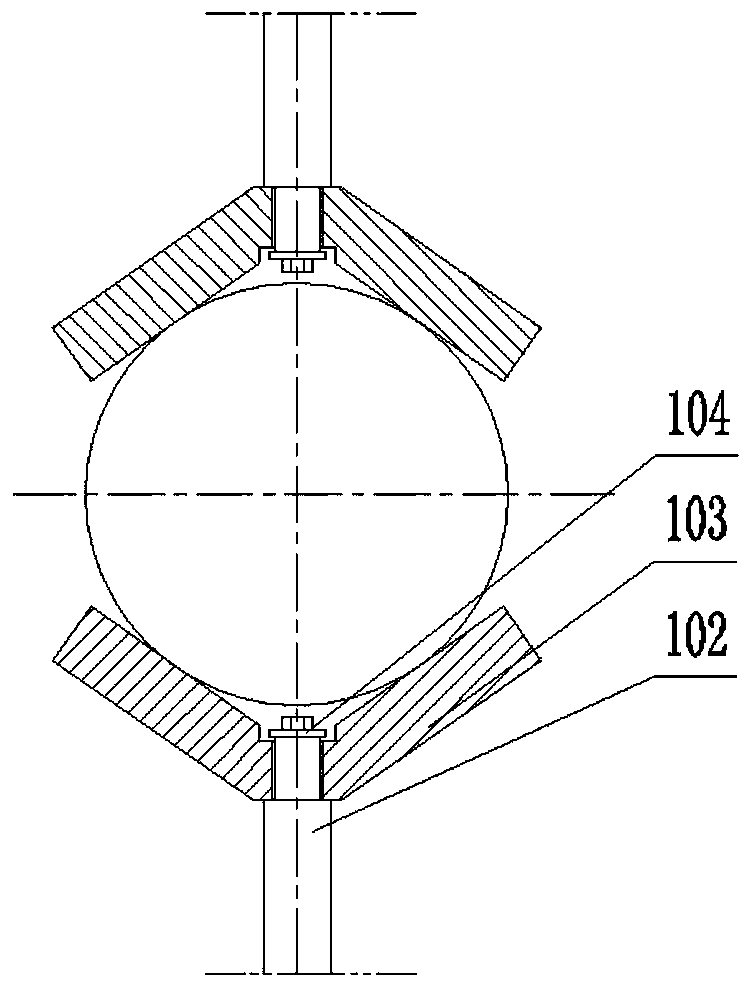

[0025] Such as figure 2 As shown, the front clamping device 2 and the rear clamping device 1 have the same structure, both of which include a shoe 105, the two ends of the shoe 105 are fixedly connected with a steering shaft 7, and the other end of the steering shaft 7 is hinged with a mani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com