S-shaped steel positioning and shaping device

A shaping device and positioning oil cylinder technology, applied in auxiliary devices, forming tools, auxiliary welding equipment, etc., can solve the problems of low production efficiency, difficult welding positioning, high processing costs, etc., to improve efficiency, improve welding accuracy and consistency, The effect of high welding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing.

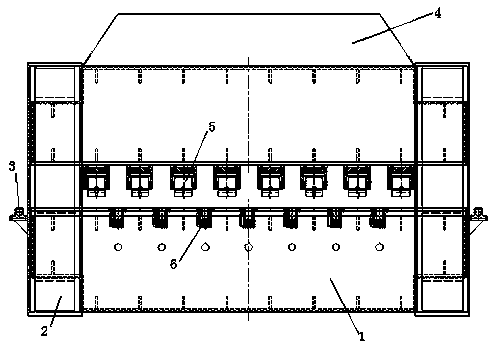

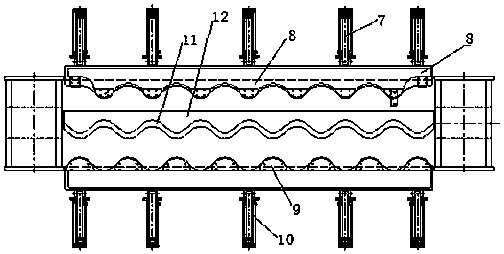

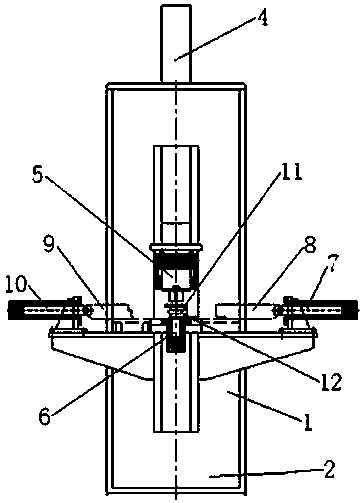

[0021] Such as Figure 1 to Figure 3 As shown, the S-shaped steel S-shaped steel positioning and shaping device includes an upper beam 4 and a lower beam 1 installed on the load-carrying gantry 2, as well as a clamping cylinder 7, a positioning cylinder 10, a pressing cylinder 5 and a shaping cylinder 6.

[0022] The top of lower crossbeam 1 is worktop, and seven shaping oil cylinders 6 are equipped with at equal intervals in the worktop, and the top of shaping oil cylinder 6 is flush with worktop, and shaping oil cylinder 6 is all positioned at the center line of worktop.

[0023] Clamping cylinder 7 and positioning cylinder 10 are arranged symmetrically on both sides of the lower crossbeam 1 working table. There are five clamping cylinders 7 and 10 for positioning. Clamping cylinder 7 is connected with clamping mold 8, and positioning cylinder 10 is connected with positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com