A kind of jelly powder mixing equipment for making orange flower cake

A technology of function and jelly, applied in mixer accessories, mixers, dissolving and other directions, can solve the problems of large temperature difference and time-consuming, and achieve the effect of convenient operation, saving manpower and avoiding poor taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

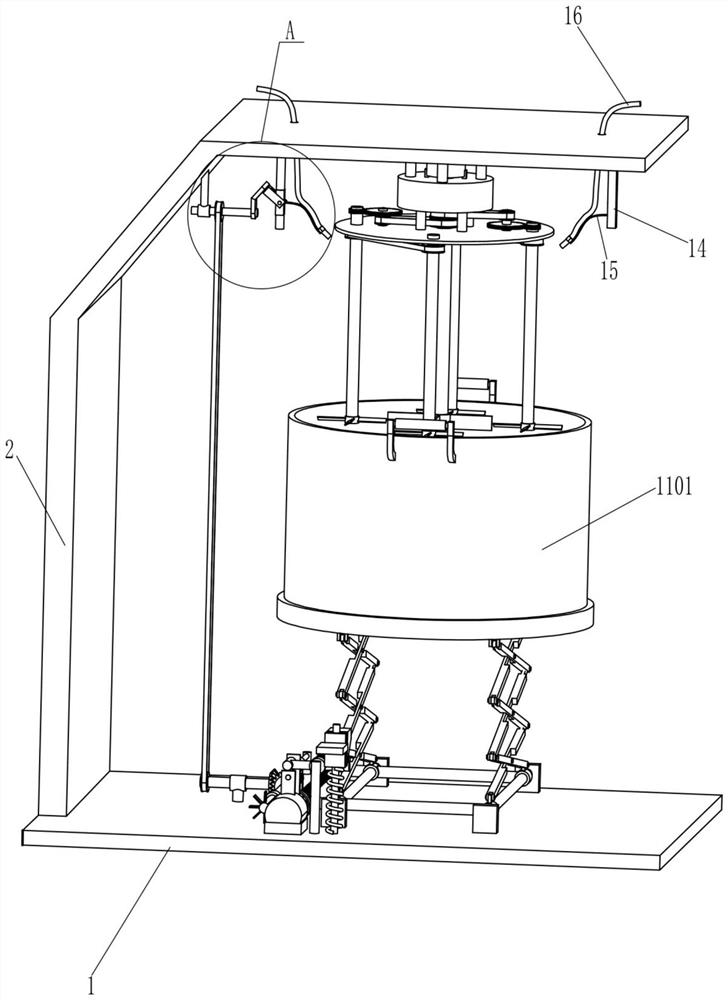

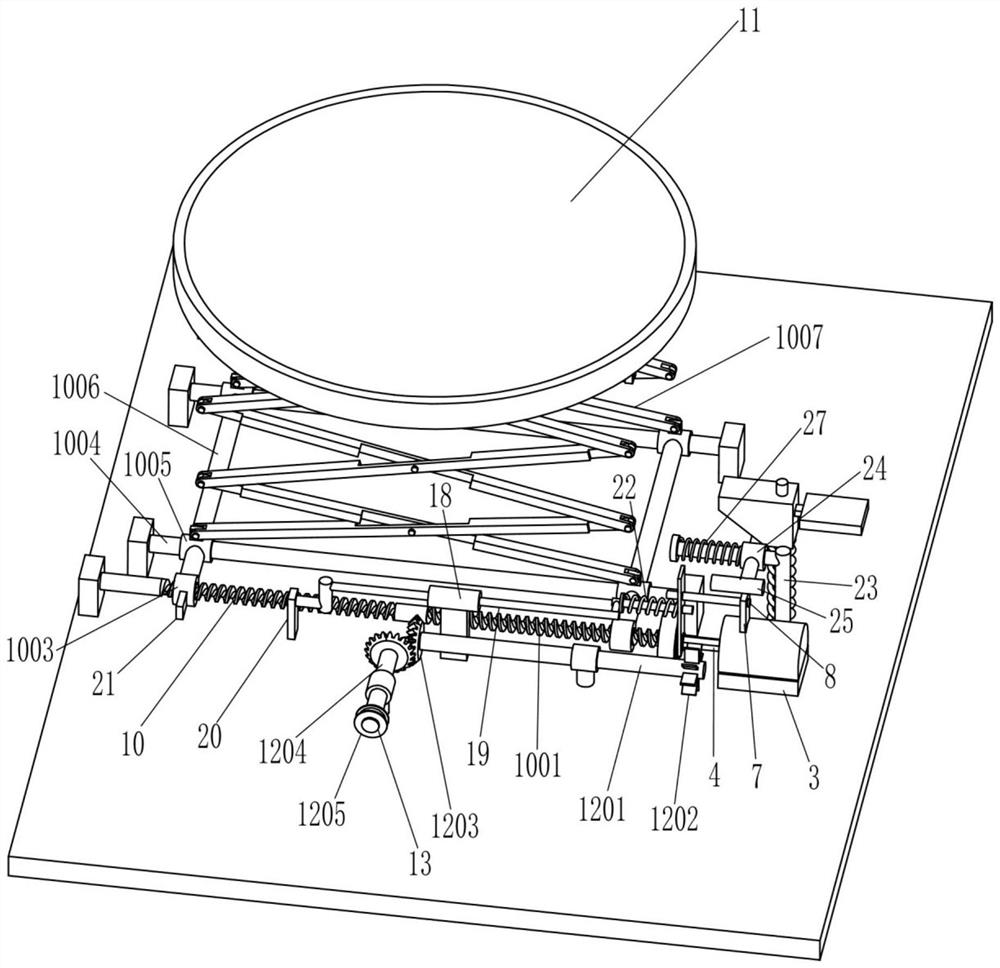

[0024] A kind of jelly powder mixing equipment used for making orange flower cake, such as Figure 1-6 As shown, it includes a bottom plate 1, a frame 2, a first motor 3, a spline shaft 4, a first sliding sleeve 5, a first clamping block 6, a first fixing block 7, a first sliding rod 8, and a first pushing block 9 , lifting assembly 10, placing plate 11, heating barrel 1101, swinging assembly 12, hot water pipe 13, fixed rod 14, second special-shaped support frame 15, cold water pipe 16 and stirring assembly 17, the left side of bottom plate 1 is fixedly installed with frame 2 , the first motor 3 is installed on the upper front side of the bottom plate 1, the spline shaft 4 is installed on the output shaft of the first motor 3, the first sliding sleeve 5 is slidably connected to the spline shaft 4, and the first sliding sleeve 5 is connected along the circumference A plurality of first clamping blocks 6 are set in the direction, the first fixed block 7 is installed on the rear...

Embodiment 2

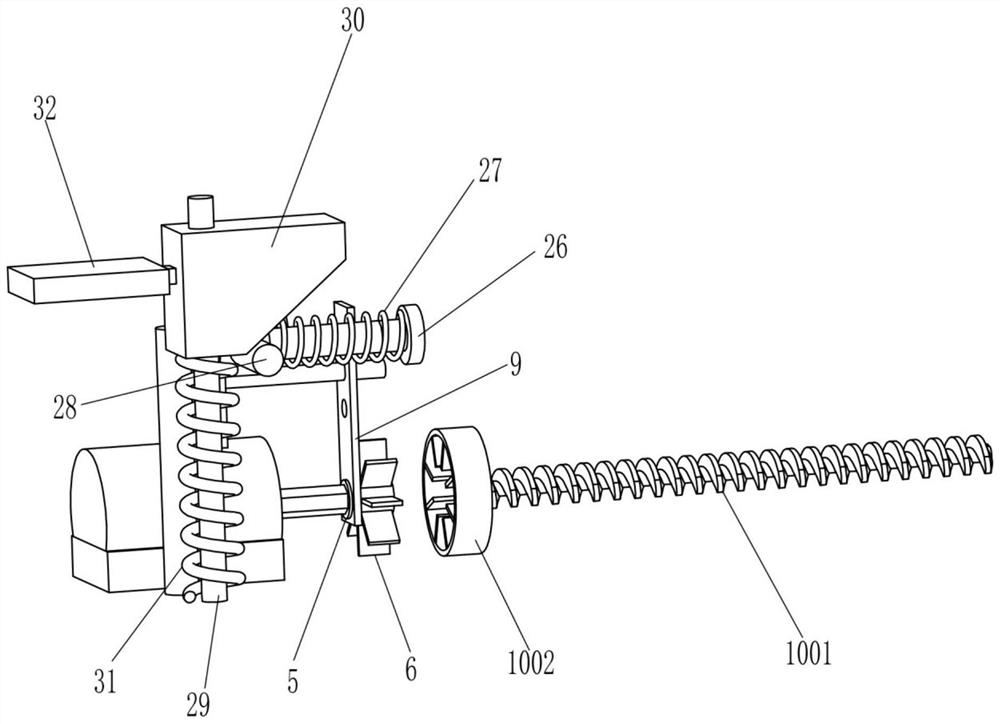

[0033] On the basis of embodiment 1, refer to Figure 2-3 As shown, it also includes guide sleeve 18, push frame 19, contact block 20, second push block 21, first spring 22, first support frame 23, third sliding sleeve 24, push rod 25, stop block 26, the first Two springs 27, contact rod 28, vertical bar 29, wedge block 30, the 3rd spring 31 and pedal 32, guide sleeve 18 is installed on the base plate 1 between screw mandrel 1001 and the first rotating rod 1201, slide on guide sleeve 18 A push frame 19 is installed, and the rear side of the push frame 19 is fixedly equipped with a contact block 20. The front end of the push frame 19 is slidably connected to the first push block 9 between the first slide bar 8 and the first sliding sleeve 5, and the screw rod The left side of the nut 1003 on the rear side of 1001 is fixedly equipped with a second push block 21, the front side of the push frame 19 is connected with a first spring 22, the front end of the first spring 22 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com