Popping elastic powder

A technology of mass fraction and emollient, which is applied in the field of bouncing powder, can solve problems such as easy oil secretion, makeup removal, skin water and oil imbalance, etc., so as to improve delicate silkiness, enhance skin care effect, and improve skin care. effect of makeup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

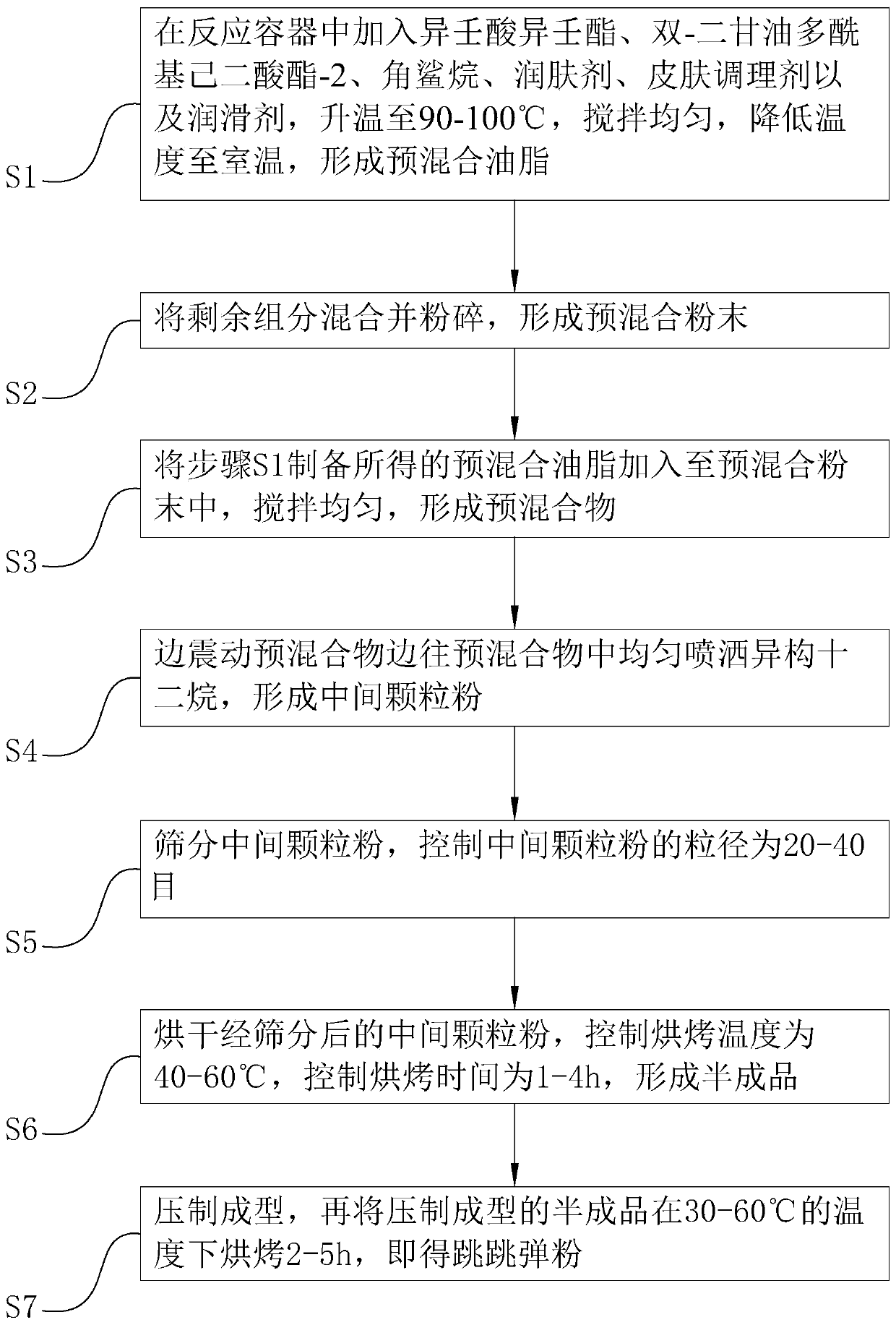

[0125] A preparation method for bouncing powder, comprising the following steps:

[0126] S1. Clean and sterilize the melting pot and other instruments and equipment. Put 2kg of isononyl isononanoate, 1kg of squalane, 1kg of bis-diglycerol polyacyl adipate-2, 5kg of emollient, and skin conditioning Add 24kg of lubricant and 7kg of lubricant into the melting pot, heat to 90°C, stir and mix evenly, and lower the temperature to room temperature to form pre-mixed grease.

[0127] S2. Put 3kg of nylon-12, 51kg of substrate and 13kg of coloring agent into a high-speed pulverizer and pulverize evenly to form a premixed powder.

[0128] S3. Add the pre-mixed oil prepared in step S1 to the pre-mixed powder, stir and mix evenly to form a pre-mixture, and after passing the test, pack the mixture and let it stand still.

[0129] S4, adding the pre-mixture into a vibrating powder sifter and spraying isododecane into the pre-mixture at the same time to form intermediate particle powder.

...

Embodiment 2

[0135] The difference with embodiment 1 is:

[0136] The consumption of each component added in step S1 and step S2 is as follows:

[0137] Isononyl Isononanoate 3kg; Squalane 2kg; Bis-Diglyceryl Polyacyl Adipate-2 2kg; Emollient 3kg; Skin Conditioner 9kg; Lubricant 4kg; Nylon-12 4.5kg; Base 60kg; Colorant 20kg.

[0138] In step S1, the temperature is raised to 95°C.

[0139] In step S6, the baking temperature is controlled to be 50° C., and the baking time is controlled to be 2.5 hours.

[0140] In step S7, the baking temperature is controlled to be 45° C., and the baking time is controlled to be 3.5 hours.

Embodiment 3

[0142] The difference with embodiment 1 is:

[0143] The consumption of each component added in step S1 and step S2 is as follows:

[0144] Isononyl Isononanoate 4kg; Squalane 3kg; Bis-Diglyceryl Polyacyl Adipate-2 3kg; Emollient 7kg; Skin Conditioner 16.5kg; Lubricant 10kg; Nylon-12 6kg; Base 42kg; Colorant 16.5kg.

[0145] In step S1, the temperature is raised to 100°C.

[0146] In step S6, the baking temperature is controlled to be 60° C., and the baking time is controlled to be 1 h.

[0147] In step S7, the baking temperature is controlled to be 60° C., and the baking time is controlled to be 2 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com