Single-stator spiral motion multi-phase permanent magnet synchronous motor capable of fault-tolerant operation

A helical motion and permanent magnet synchronization technology, which is applied to synchronous motors with stationary armatures and rotating magnets, electric components, magnetic circuits, etc., can solve the problems of bulky machines, poor positioning accuracy, and complex control, and achieve The effect of reducing the order of higher harmonics, reducing ohmic loss, and improving the winding coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

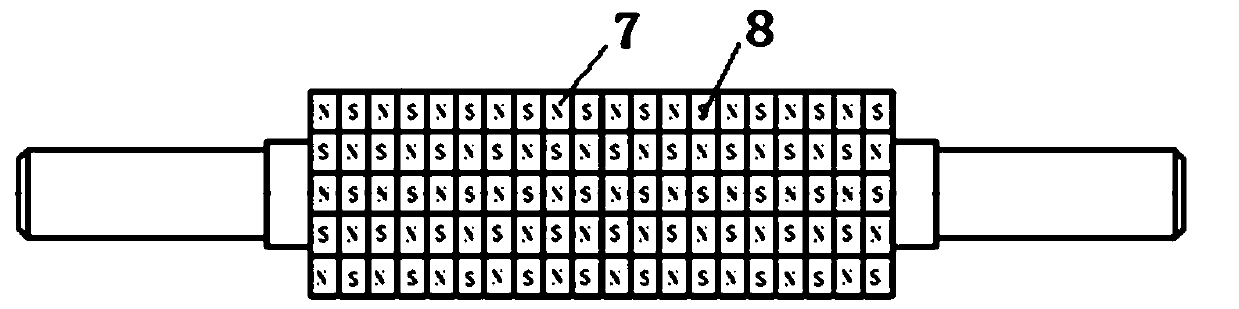

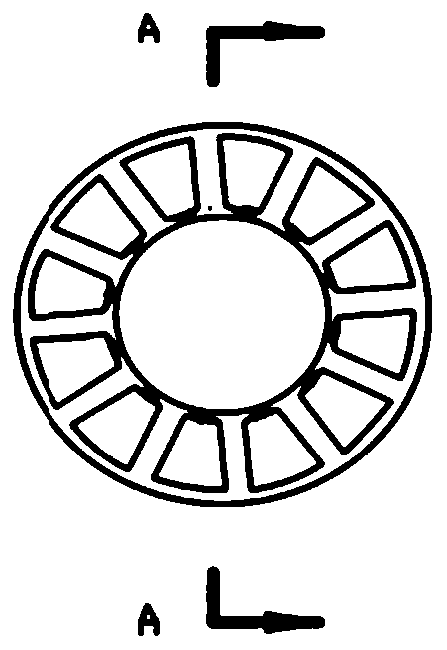

[0026] Such as figure 1 As shown, the single-stator helical multi-phase permanent magnet synchronous motor capable of fault-tolerant operation described in this embodiment includes a stator and a rotor, the rotor is located inside the annular stator, and the rotor includes a magnetically conductive rotating shaft 9 and its surfaces are alternately distributed The polarity of the permanent magnet is N and S. The stator includes a stator core 5 and a stator winding 6. The stator core 5 is provided with a helical tooth groove, and the direction of rotation of the helical tooth groove is consistent with the direction of the motor axis. The positive direction is a right-handed spiral relationship, and the spiral tooth slots are clockwise in the order of A, D, C, F, B, E six-phase windings, and the six-phase windings adopt a six-phase double Y-shifted 30° winding structure.

[0027] Such as Figure 3-10 As shown, the three-phase belts of windings A, B, and C have a difference of 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com