Image calibration method and device, electronic equipment and storage medium

A calibration method and image technology, applied in the field of sewing\sewing, can solve the problems of small memory storage space, error-prone, and many steps, and achieve the effect of low time complexity and space complexity, less error-prone, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

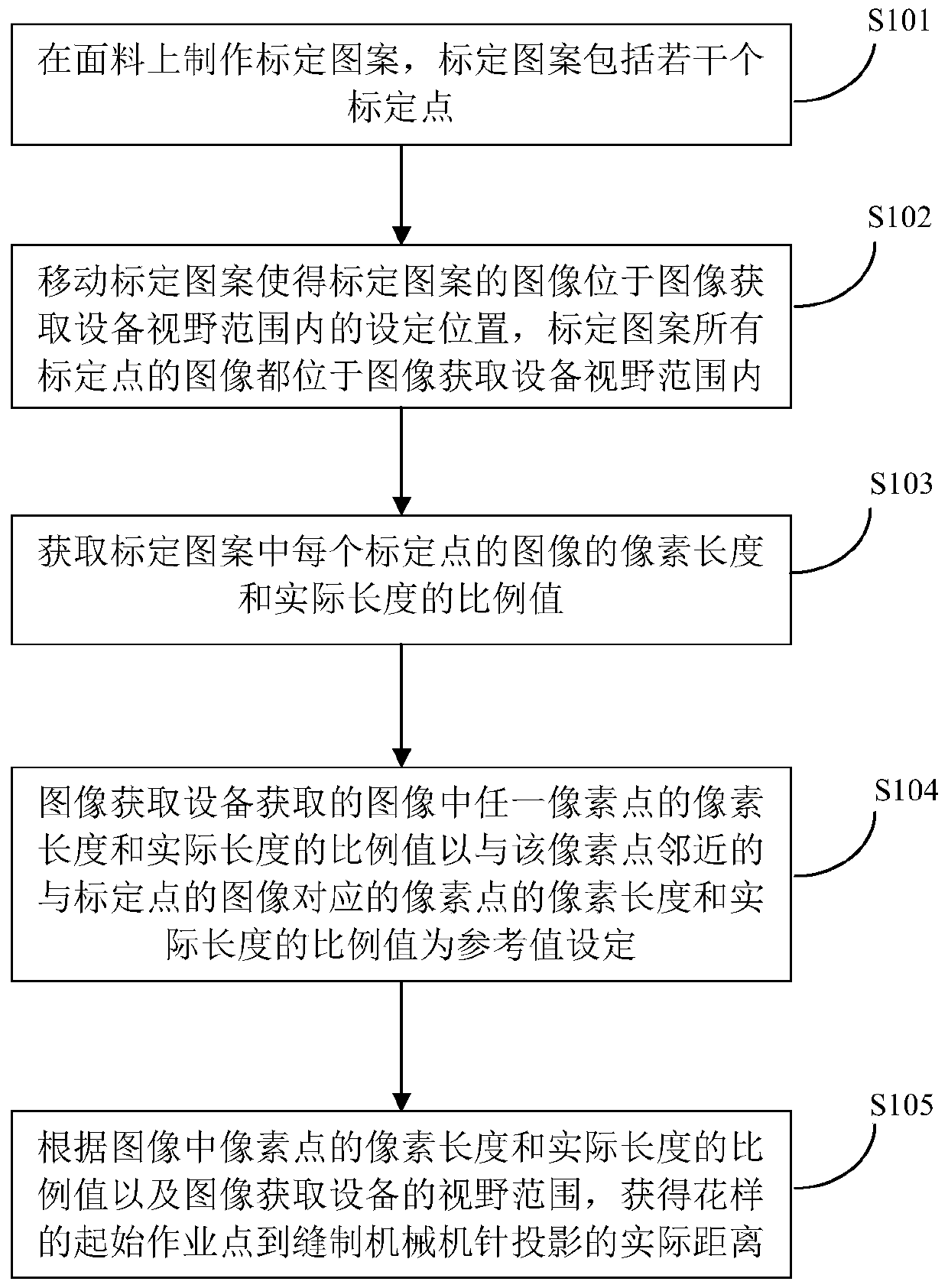

[0049] figure 1 It is a flowchart of the image calibration method in this embodiment, and the image calibration method includes the following steps.

[0050] S101. Make a calibration pattern on the fabric, where the calibration pattern includes several calibration points.

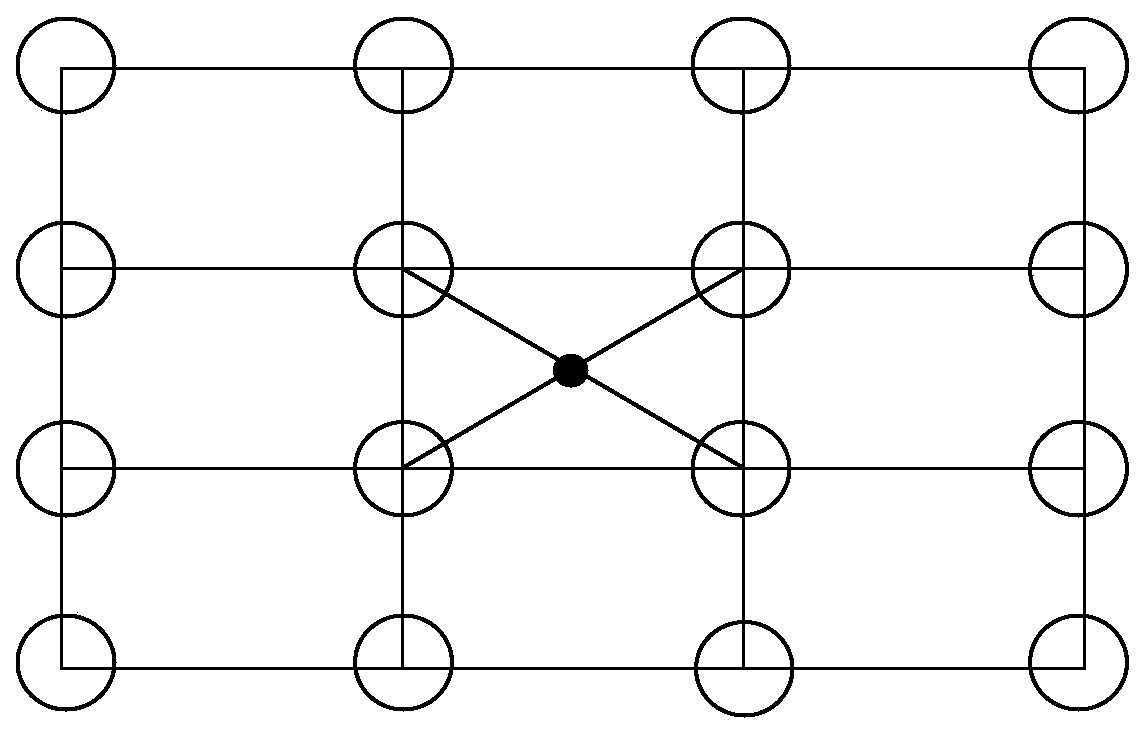

[0051] In this application, a pattern refers to a pattern formed by a real object, and an image refers to an image obtained by an image acquisition device, generally a digital image. In order to perform image calibration correctly, it is necessary to make a calibration pattern on the fabric first. Embroidery machines generally use flat embroidery to embroider calibration patterns on fabrics. Considering the accuracy of image calibration and the convenience of making calibration patterns, calibration patterns usually include several regular geometric figures with the same shape, and special points of regular geometric figures, such as the vertices and geometric centers of geometric figures, are used as cal...

Embodiment 2

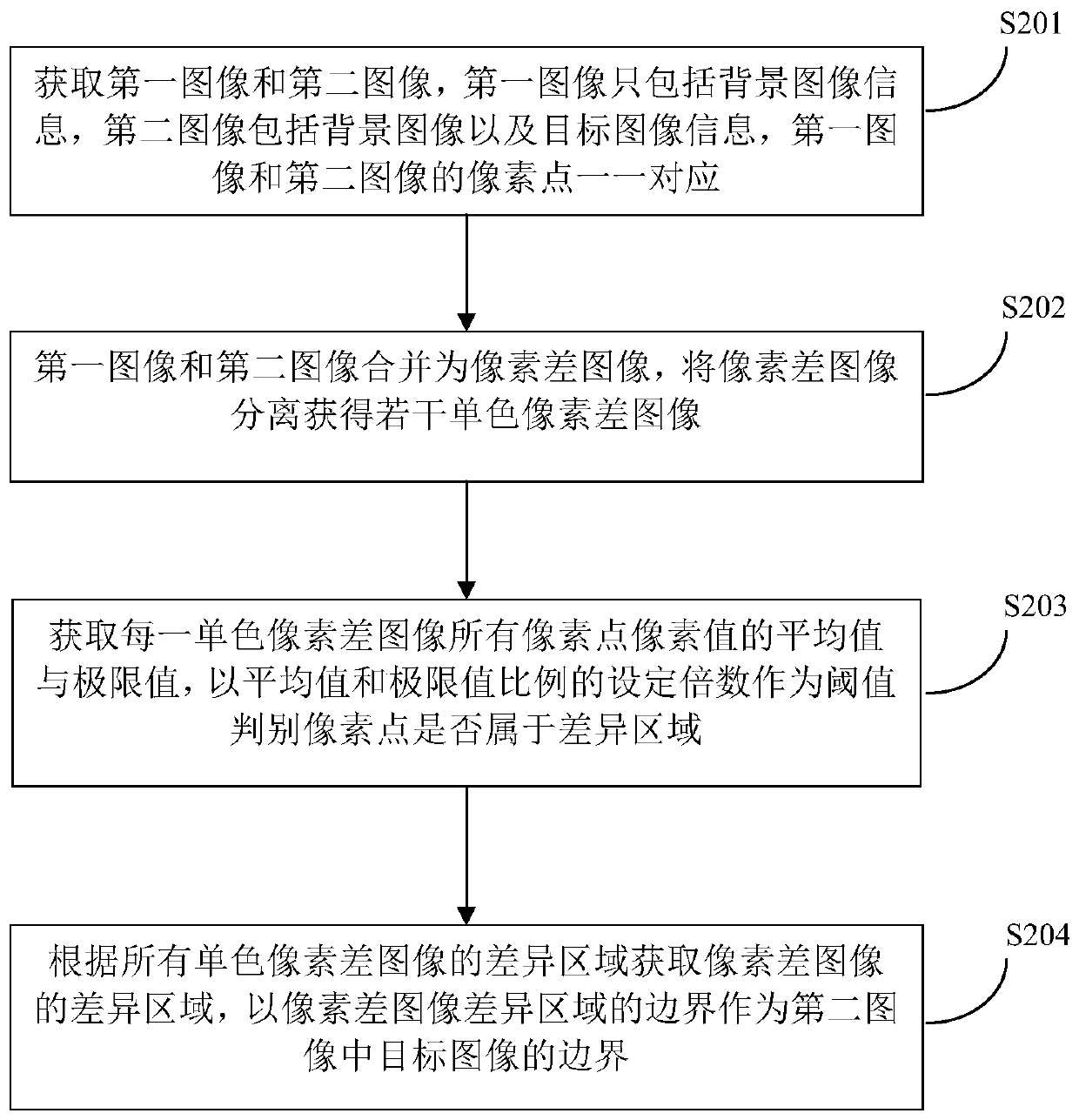

[0070] This embodiment provides a method for recognizing a target image. The image acquired by the image acquisition device is an overall image, only a part of which is the image of the target pattern, and the other part is an unnecessary background image. The recognition of the target image is to extract the target image from the overall image and mark the boundary between the target image and the background image.

[0071] At present, many methods for identifying target images have been reported, such as the widely used GrabGut algorithm. The general steps of the GrabGut algorithm are as follows: 1. Define one or more rectangles containing the target image in the overall image, and automatically define the image outside the rectangle as the background image; 2. Use the Gaussian mixture model (GMM) to compare the background image and the target image Modeling, marking undefined pixels as possible background images or target images; 3. Any pixel in the rectangle is considered...

Embodiment 3

[0089] Figure 4 It is a schematic diagram of the structure of the image labeling device in this embodiment. The image marking device 40 includes a marking pattern making device 41 , a pattern moving device 42 , a proportional value obtaining device 43 , a proportional value setting device 44 and a distance obtaining device 45 . The pattern moving device 42 is used to move the calibration pattern so that the image of the calibration pattern is located at a set position within the field of view of the image acquisition device, and the images of all calibration points of the calibration pattern are located within the field of view of the image acquisition device. The ratio value obtaining means 43 is used for obtaining the ratio value between the pixel length and the actual length of the image of each calibration point in the calibration pattern. Proportional value setting device 44 is used for the pixel length and the actual length of any pixel point in the image acquired by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com