Multistage median filtering method for smooth denoising of metallographic image

An image smoothing, smoothing and denoising technology, applied in image enhancement, image analysis, image data processing, etc., can solve problems such as undistinguished boundary signal and noise signal, destruction of detailed information such as metallographic boundaries, and metallographic recognition errors. , to achieve the effect of good boundary protection performance, good metallographic boundary protection performance, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

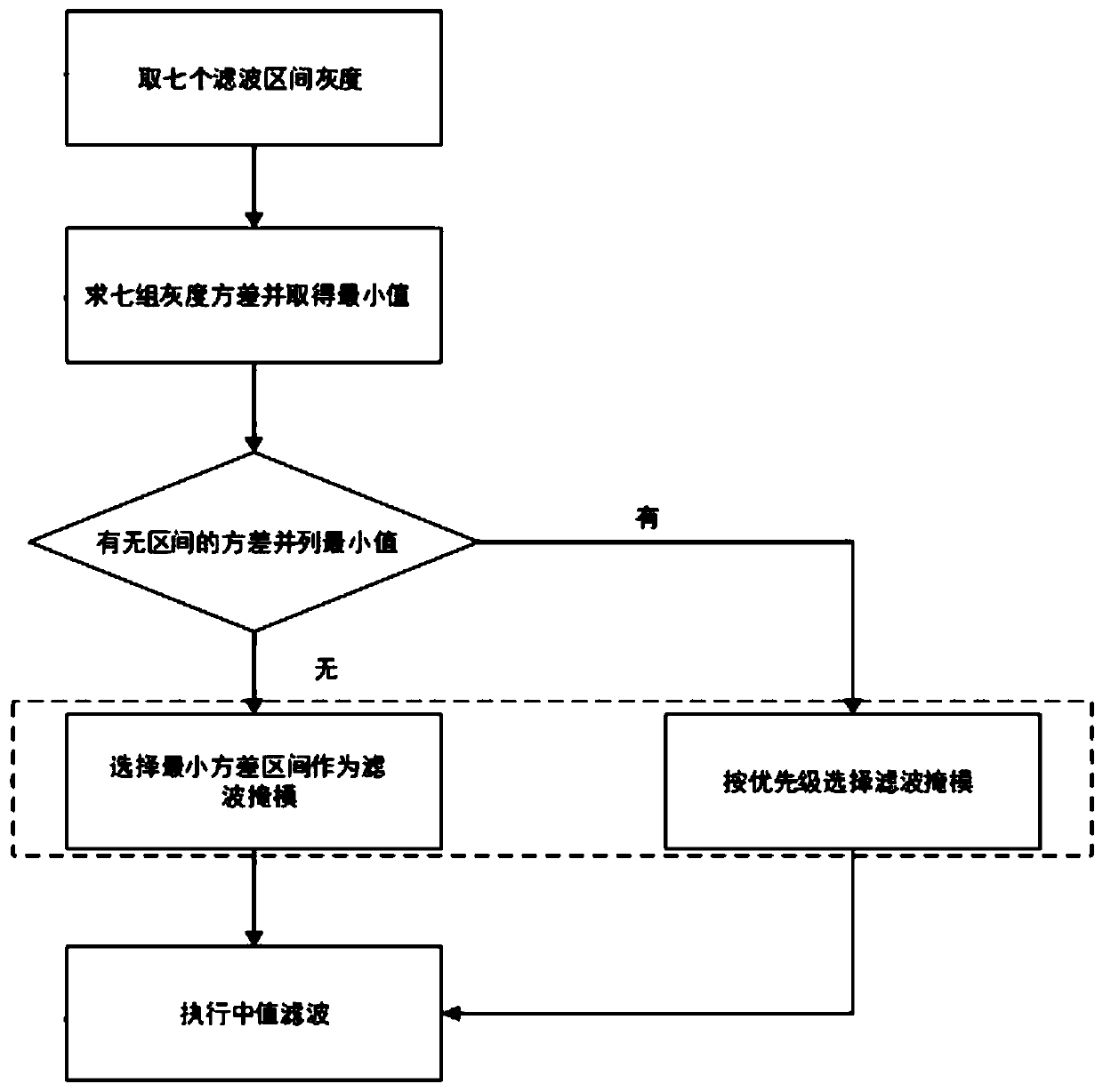

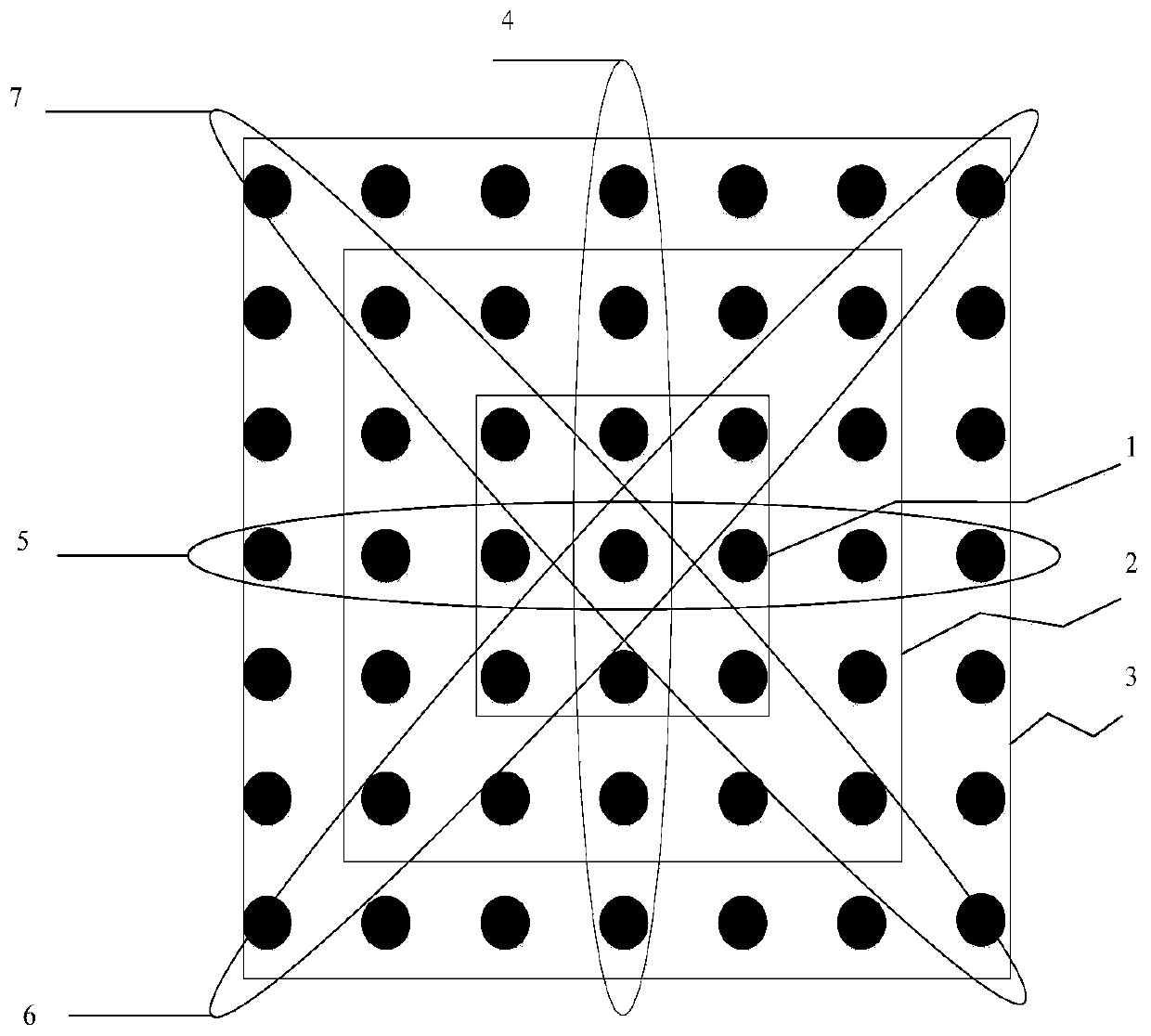

[0024] An embodiment of the present invention provides a multi-level median filtering method for smoothing and denoising metallographic images, taking ordinary carbon steel metallographic images as an example, such as figure 1 As shown, including the following steps:

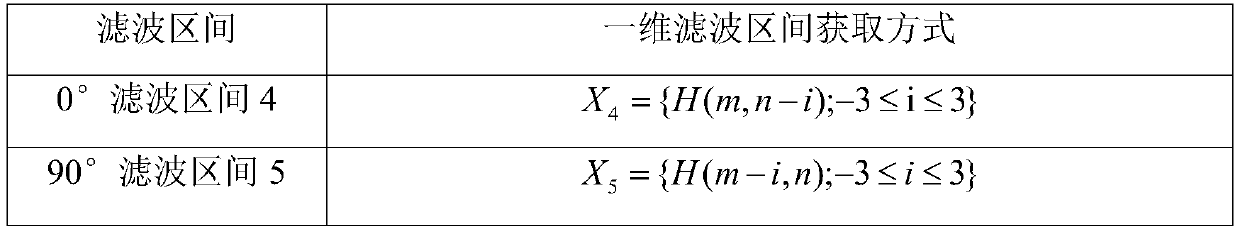

[0025] S1 extracts the general carbon steel metallographic image from the metallographic microscope, and uses a certain pixel as the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com