Design method of lightweight double-layer structure of palm mattress

A double-layer structure and design method technology, applied in the direction of design optimization/simulation, can solve the problems of excess brown mattress materials and increase the production cost of brown mattresses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1. A design method for lightweight double-layer structure of palm mattress, the design method is as follows:

[0069] Design the brown mattress with a length of 2000mm, a width of 1800mm and a thickness of 120mm. The double palm mattress is divided into an upper mattress layer and a lower mattress layer, and the thickness of the lower mattress layer is designed to be 4 times the thickness of the upper mattress layer, that is, the thickness of the upper mattress layer is 24mm, and the thickness of the upper mattress layer is 96mm.

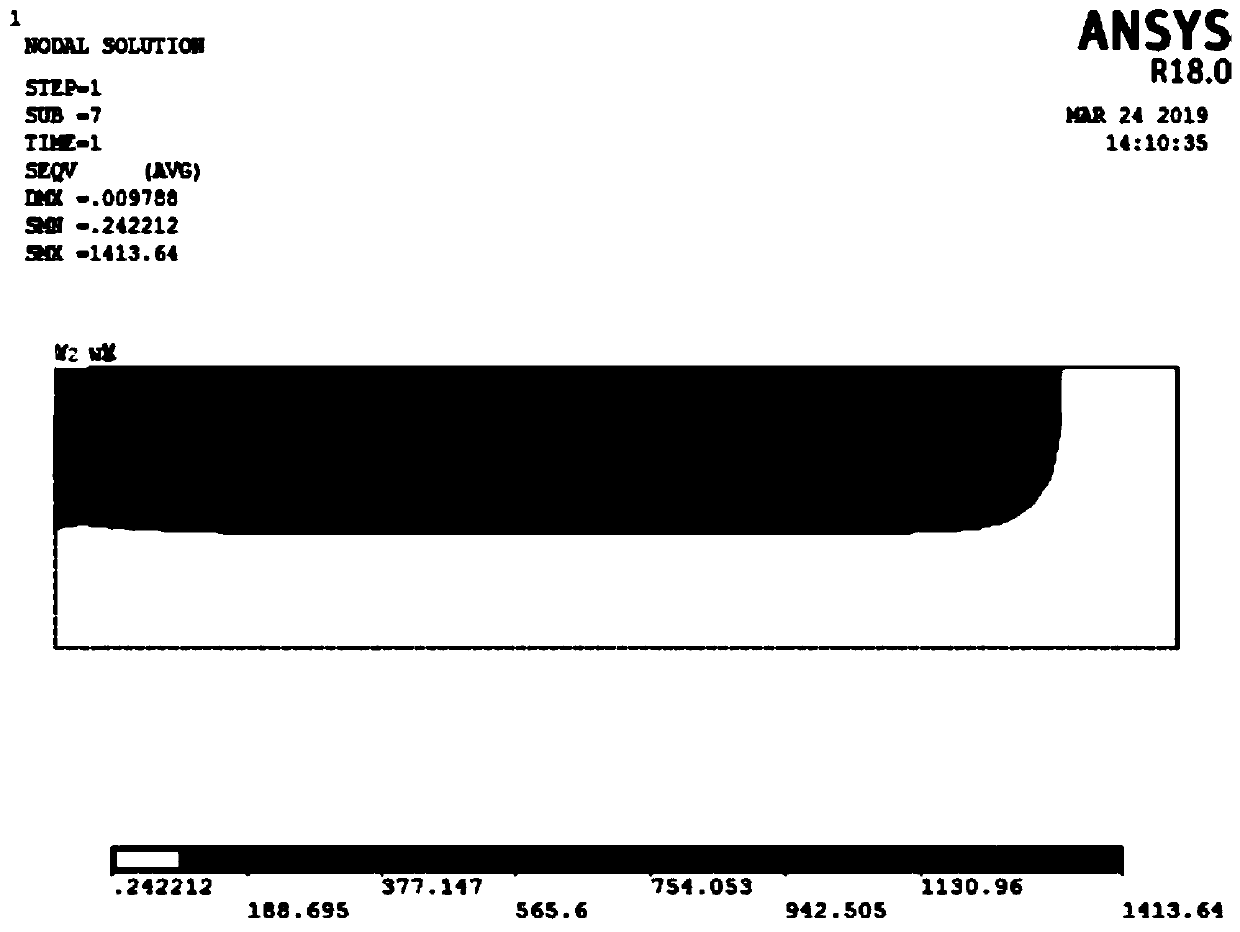

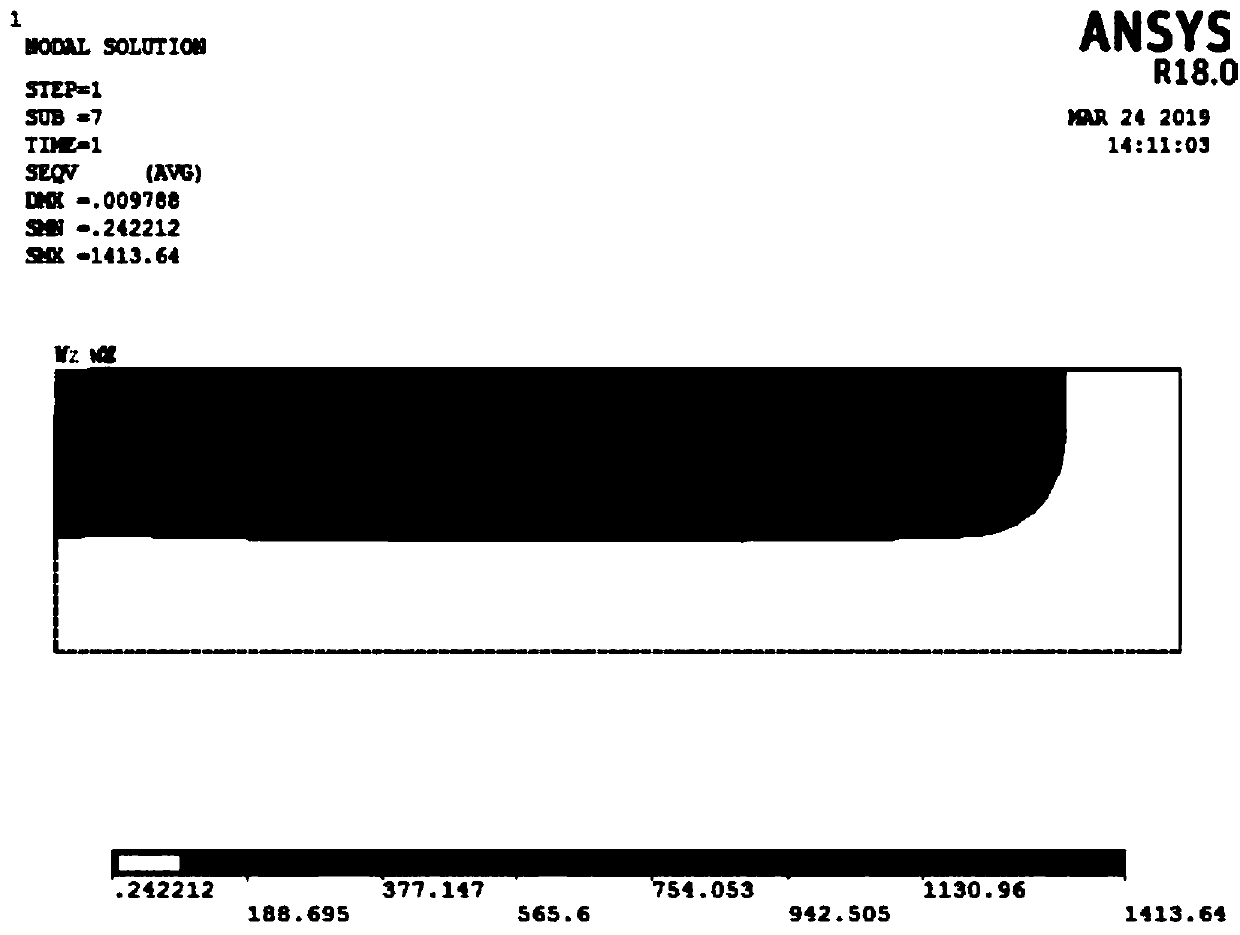

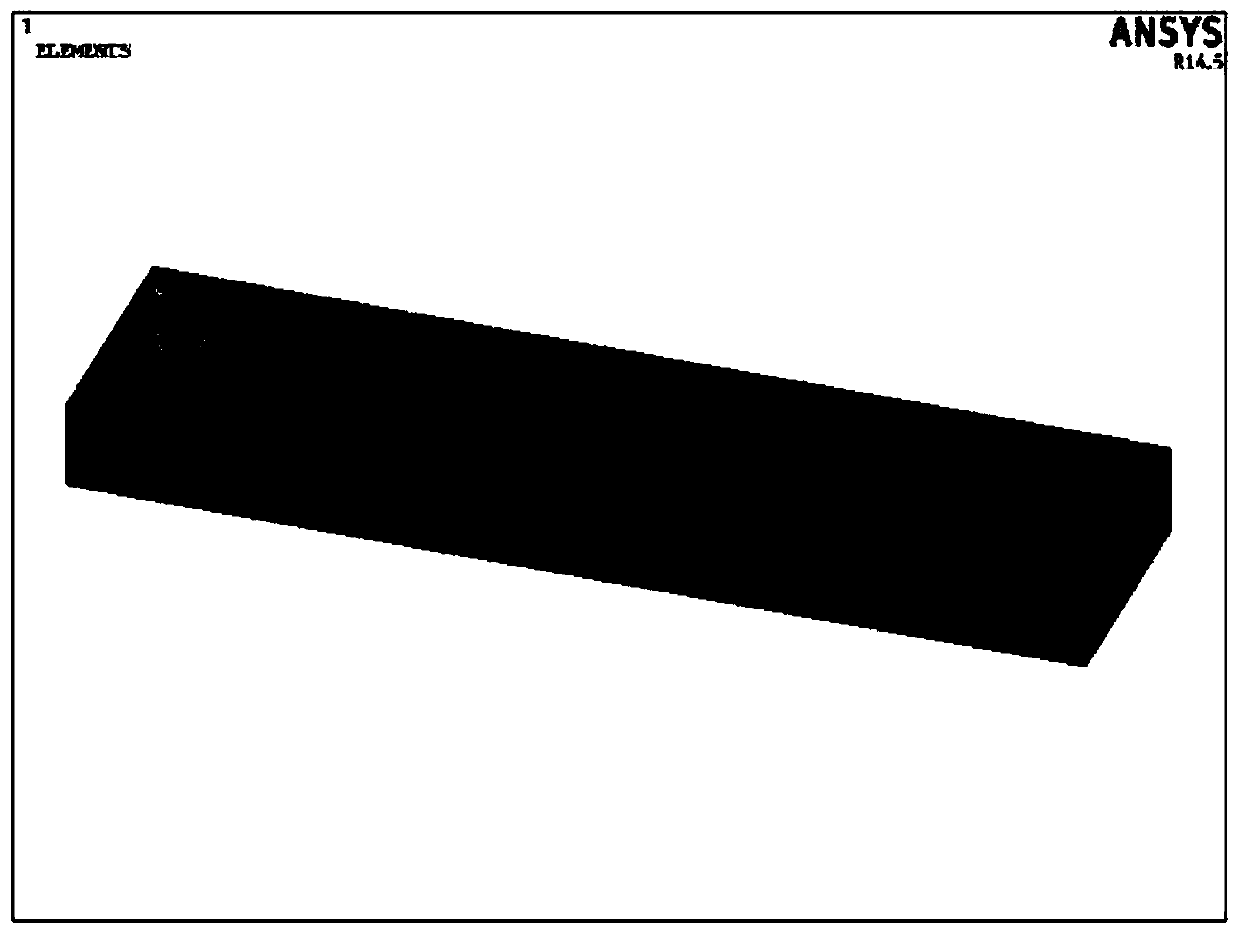

[0070] Firstly, use ANSYS software to establish the mountain palm material model of the mattress. Using the method of finite element solution, the brown mattress model corresponding to the length, width and thickness is established with the brown material model. Then apply human body load on the brown mattress model, the area of the load is 1700mm×800mm, and the weight is 80kg; the stress deformation test is performed on the mattr...

Embodiment 2

[0073] Example 2. A design method for a lightweight double-layer structure of a brown mattress, the model building method and the stress deformation test method of the present embodiment are the same as the embodiment 1. In this embodiment, the brown mattress with a length of 1800mm, a width of 1600mm and a thickness of 120mm is designed as a lightweight double mattress layer structure. The thickness of the lower mattress layer is designed to be 3.5 times the thickness of the upper mattress layer, the thickness of the upper mattress layer is 26.7mm, the thickness of the lower mattress layer is 93.3mm, and the lower winding value of the upper mattress layer and the lower mattress layer Select the plane where the stress center of the mattress layer is located, and select a deflection value within 10mm from the stress center of the mattress layer as the downdeflection value. Use the deflection values of the upper mattress layer and the lower mattress layer to set the density o...

Embodiment 3

[0075] Example 3. A design method for a lightweight double-layer structure of a brown mattress, the model building method and the stress deformation test method of the present embodiment are the same as the embodiment 1. In this embodiment, the brown mattress with a length of 1800mm, a width of 1600mm and a thickness of 150mm is designed as a lightweight double mattress layer structure. The thickness of the lower mattress layer is designed to be 3 times the thickness of the upper mattress layer, the thickness of the upper mattress layer is 37.5mm, the thickness of the lower mattress layer is 112.5mm, and the lower winding value of the upper mattress layer and the lower mattress layer Select the plane where the stress center of the mattress layer is located, and select a deflection value within 6mm from the stress center of the mattress layer as the downdeflection value. Use the deflection values of the upper mattress layer and the lower mattress layer to set the density of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com