Damping friction support

A damping and steel damping technology, which is applied to bridge parts, bridges, building components, etc., can solve the problems of poor shock absorption and energy consumption of bridges, large horizontal displacement of supports, and influence on bridge safety, etc. Low cost, enhanced rigidity and the effect of transmitting horizontal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

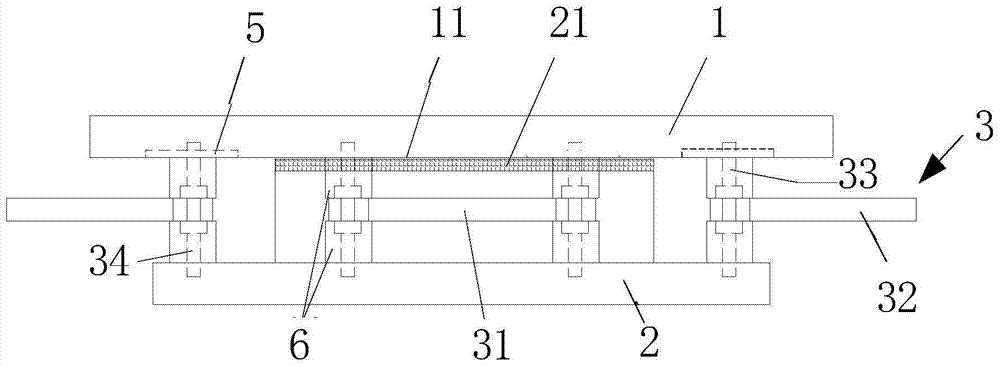

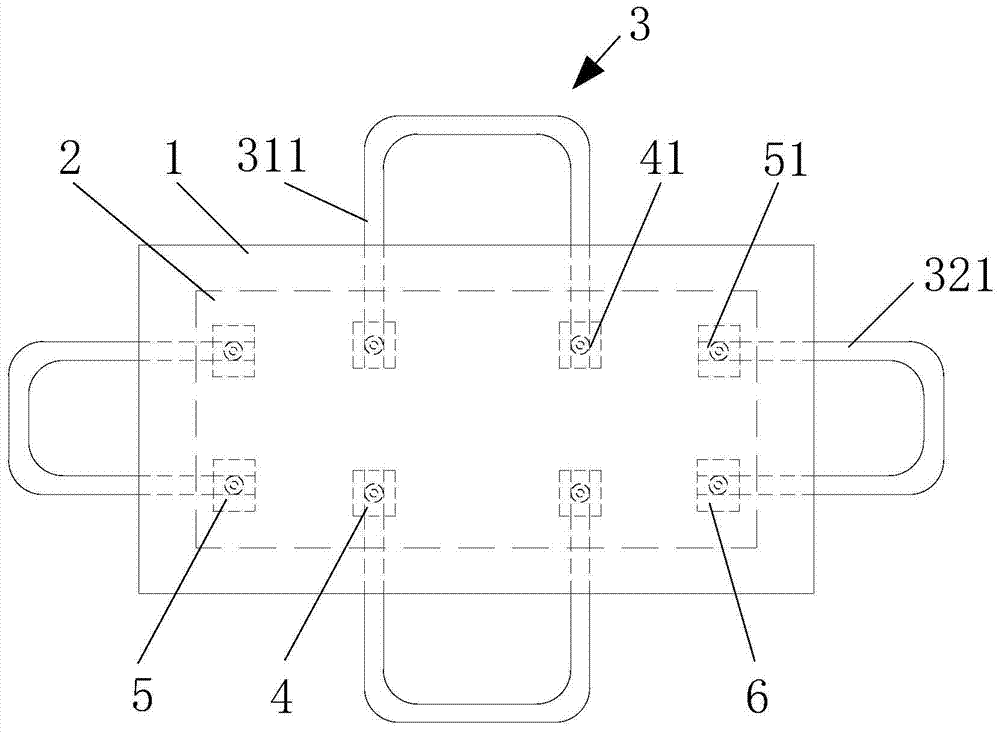

[0027] Such as figure 1 , figure 2 The embodiment of the damping friction bearing of the present invention is shown. The damping friction bearing is arranged between the main girder of the girder bridge and the bridge pier or abutment, and is used to provide shock-absorbing limit support for the girder bridge, and to a certain extent prevent The possible girder drop phenomenon of continuous girder bridges under the action of large earthquakes. The damping friction support of this embodiment includes an upper seat plate 1 and a lower seat plate 2, the upper seat plate 1 is fixed on the bottom plate of the bridge beam, the lower seat plate 2 is fixed on the pier, and the upper seat plate 1 and the lower seat plate 2 are slidably matched to meet Bridge displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com