Loading head for load calibration of a wind tunnel balance

A technology of wind tunnel balance and loading head, which is applied in the testing of machines/structural components, instruments, measuring devices, etc. It can solve problems such as layout form, weight-to-stiffness ratio that are not optimized enough, affect balance calibration performance and accuracy, etc., and achieve reduction Effects of weight, improved calibration level, and accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

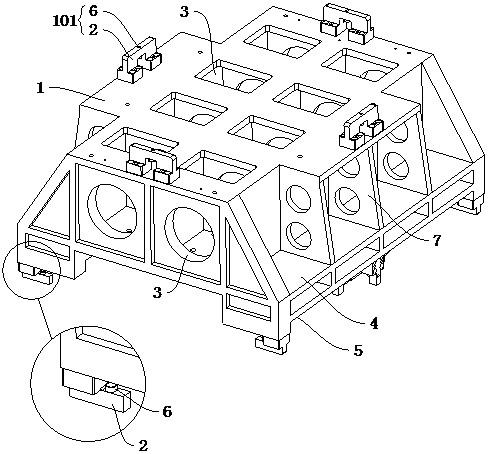

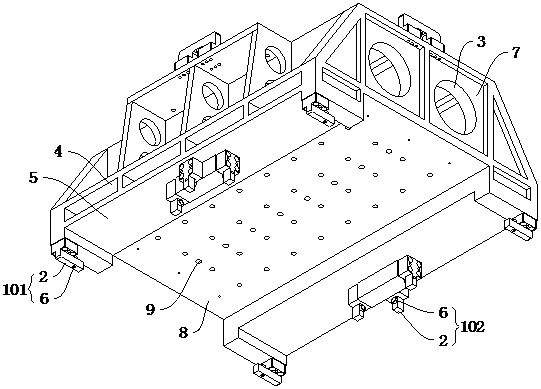

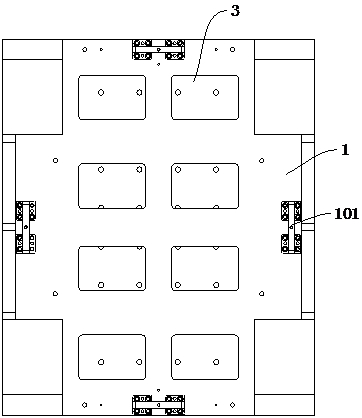

[0044]For the specific application of the wind tunnel balance, the loading head needs to apply a load force in its calibration work to help the calibration of the wind tunnel balance. The calibration work requires high rigidity and force application accuracy of the loading head. The existing loading head is in the layout form, In terms of stiffness, installation and positioning, it is difficult to meet the calibration requirements of the simulated wind tunnel test belt strut calibration and higher precision, and it is difficult to make the calibration of the wind tunnel balance reach a higher level. This embodiment discloses a loading head structure to solve the technical problems in the prior art.

[0045] Specifically, as Figure 1 to Figure 6 As shown, the technical solution disclosed in this embodiment is:

[0046] A wind tunnel balance load calibration loading head, including a body, a plurality of horizontal loading mechanisms 102 and longitudinal loading mechanisms 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com