Design scheme of box parameterization process template

A design scheme and parametric technology, which is applied in the design scheme field of the box parameterized process template, can solve the problems of high manufacturing risk, large quantity, and long box process preparation period, and achieve the effect of improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

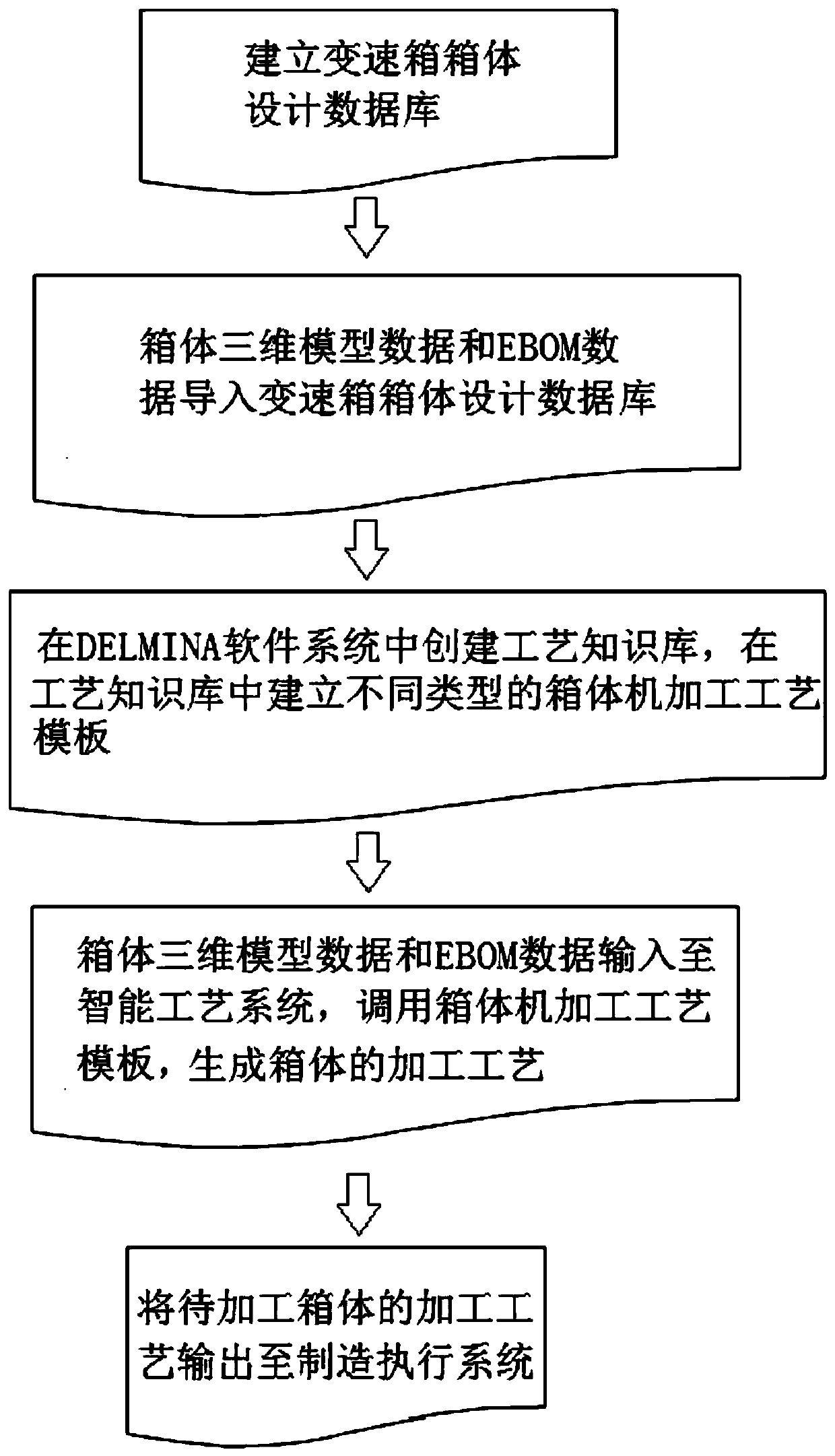

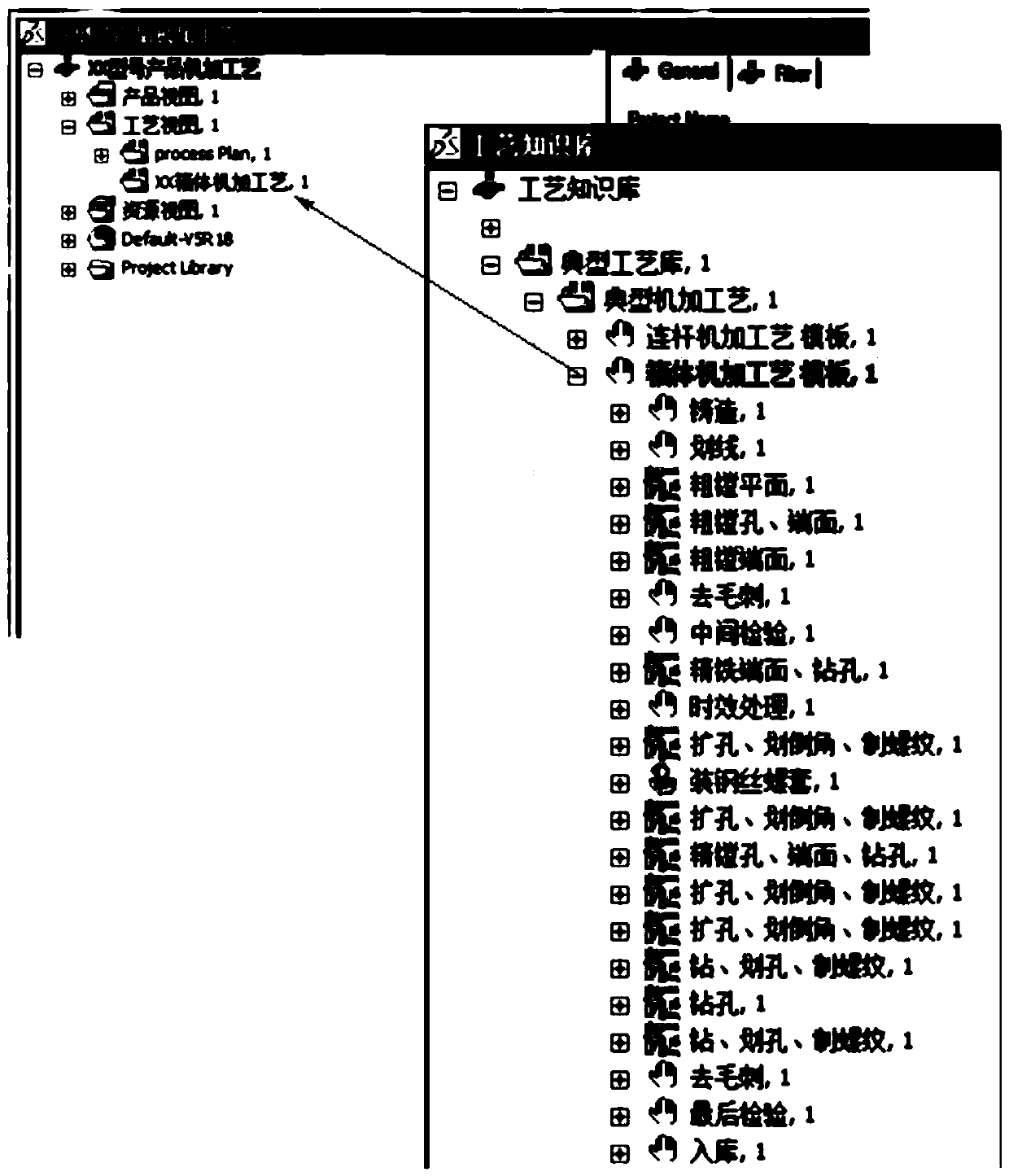

[0017] This embodiment discloses a design scheme of a box parametric process template, see figure 1 with figure 2 , including the following steps:

[0018] 1) Establish a gearbox case design database on the computer, and store the gearbox case design database in a PDM (Product Date Management, product data management) system.

[0019] 2) Import different types of box 3D model data and EBOM (Engineering Bill of Material) data into the gearbox box design database.

[0020] 3) Create a process knowledge base in the intelligent process system, and establish different types of box machining process templates in the process knowledge base. The box machining process template includes processing flow information, processing step information, processing content information, equipment information, tooling information and processing parameter information. In this embodiment, the process knowledge base created by the intelligent process system is based on the process knowledge base fu...

Embodiment 2

[0025] This embodiment discloses a relatively basic implementation, see figure 1 with figure 2 , including the following steps:

[0026] 1) Establish a gearbox case design database on the computer, and store the gearbox case design database in a PDM (Product Date Management, product data management) system.

[0027] 2) Import different types of box 3D model data and EBOM (Engineering Bill of Material) data into the gearbox box design database.

[0028] 3) Create a process knowledge base in the intelligent process system, and establish different types of box machining process templates in the process knowledge base. In this embodiment, the process knowledge base created by the intelligent process system is based on the process knowledge base function of the DELMINA (DigitalEnterprise Lean Manufacturing Interactive Application, digital enterprise interactive manufacturing application software) software system, the process knowledge base function of the software system, and th...

Embodiment 3

[0033] The main structure of this embodiment is the same as that of Embodiment 2. Further, in step 3), the box machining process template includes processing flow information, processing step information, processing content information, equipment information, tooling information and processing parameter information.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com