Air pressure micromanipulation system and method for micron-sized particle sample

A technology of manipulation system and air pressure system, which is applied in the microscopic field of materials and mineral samples, can solve the problems of poor voltage control and release position, and achieve the effect of controllable direction and force and high capture success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] The method specifically includes the following steps (attached Figure 4~6 screenshot for video):

[0059] Step 1. Use simulated lunar soil particles of different sizes (10-200 μm) and disperse them on the glass slide;

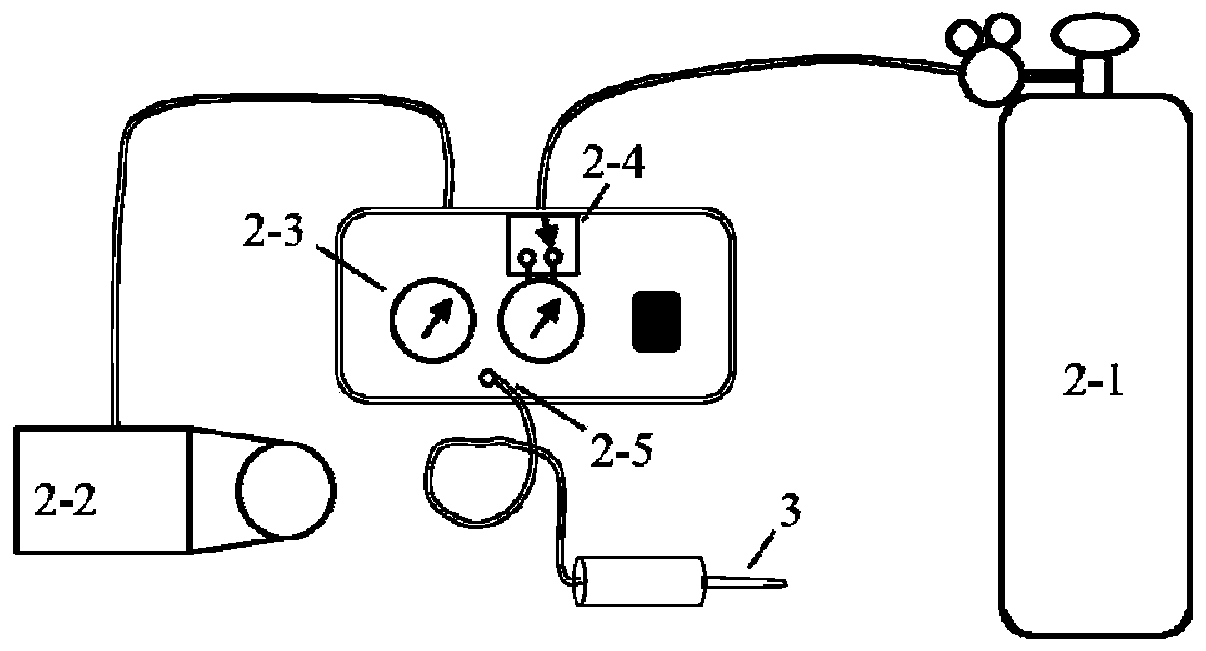

[0060] Step 2. Make a hollow tip with a glass tip puller (eg figure 2 );

[0061] Step 3. Use the binocular lens of a stereo microscope to find a particle with a particle size of about 40 μm, and move the tip of the glass needle point above the sample by means of a three-axis movement of the microcontroller (such as Figure 4 ), turn on the vacuum function of the air pressure controller, adjust the air pressure to about 500psi, absorb the particles to the tip of the needle tip, and then raise the glass needle tip to a safe area;

[0062] Step 4: Move the sample stage to another position, and use the microcontroller to slowly bring the glass needle tip close to the sample stage. When the observation system sees that the glass needle tip is gradually f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hollow diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com