Energy-saving combustion test furnace for testing burner performance

A combustion test and energy-saving technology, which is applied in the field of test furnaces, can solve the problems of single use, narrow range of test burner power, and failure to consider the energy saving of the furnace body, so as to achieve good energy-saving effects and ensure test safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

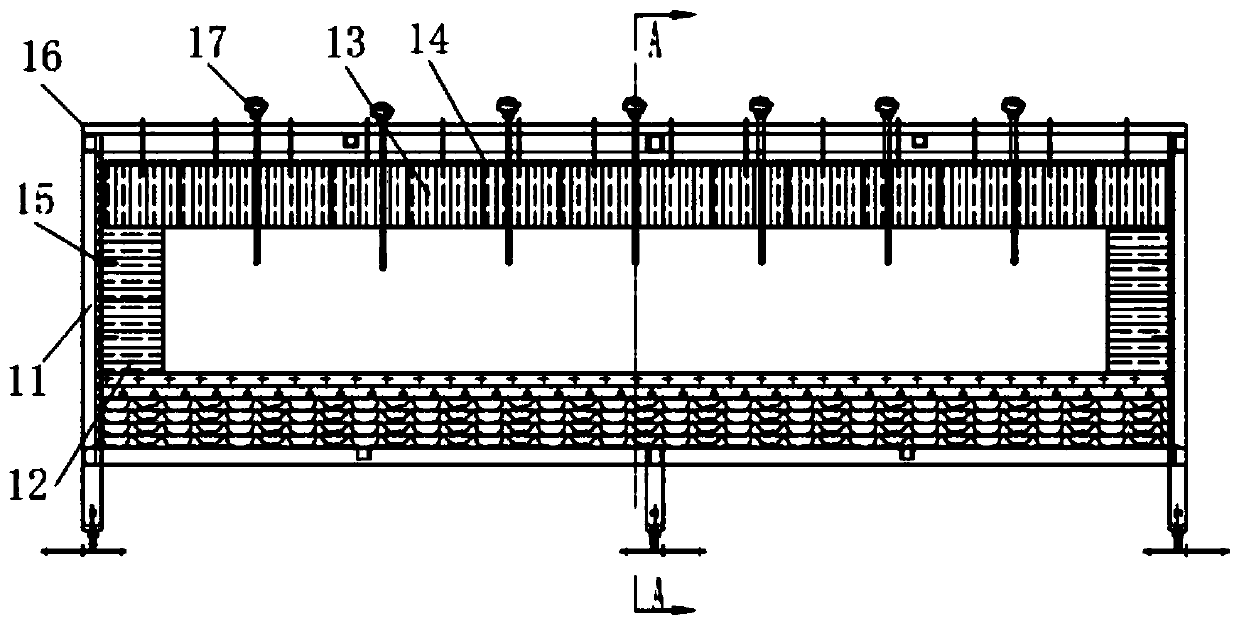

[0032] Such as figure 1 and figure 2 As shown, the present invention provides an energy-saving combustion test furnace for testing the performance of the burner, including: a furnace body, an air supply and exhaust system, a combustion support system and a detection data acquisition mechanism. The surroundings of the kiln body are closed, including a kiln frame 11 and a refractory insulation layer 12; the refractory insulation layer 12 is a cotton structure, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com