Automatic swinging air blowing equipment and working method

A working method and equipment technology, applied in the field of fluid dynamics, can solve the problems of shortened life, discomfort of facing the crowd, and waste of manpower and material resources, etc., and achieve the effect of automatic swing of the wind direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

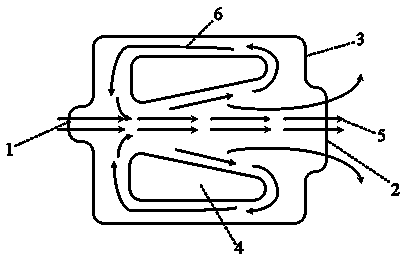

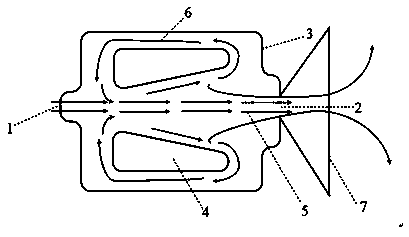

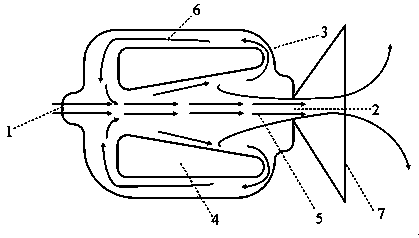

[0024] Combine below Figure 1~3 The operation process of an automatic swing blowing device is described in detail.

[0025] The main flow flows from the air inlet to the air outlet along the axis. As the vertical distance between the edge of the wind deflector and the central axis gradually increases, the pressure at the smaller vertical distance near the air inlet end is smaller, and the vertical distance near the air outlet end is longer. The pressure in the big place is higher, so there is a pressure difference between the two places;

[0026] Due to the closed environment formed by the closed shell, with the effect of the pressure difference, part of the fluid in the main flow where the pressure is higher will flow back along the wind deflector and around the wind deflector to the lower pressure area and disturb the main flow. Due to the non-uniformity of the disturbance, the fluid at the air outlet will gather and swing back and forth within the scope of the restrictor;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com