Hydraulic system for hydraulic hammer

A hydraulic system and hydraulic hammer technology, applied in the hydraulic system field of hydraulic hammer, can solve the problems of high piling frequency, high requirements for stability and rapidity of reversing, poor reliability, etc., and achieve the effect of improving operation efficiency and maintaining high efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

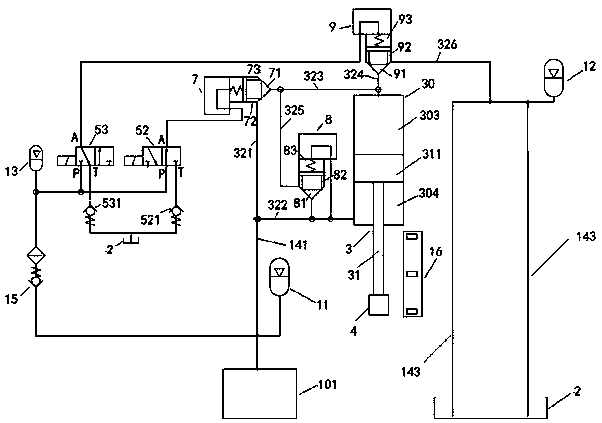

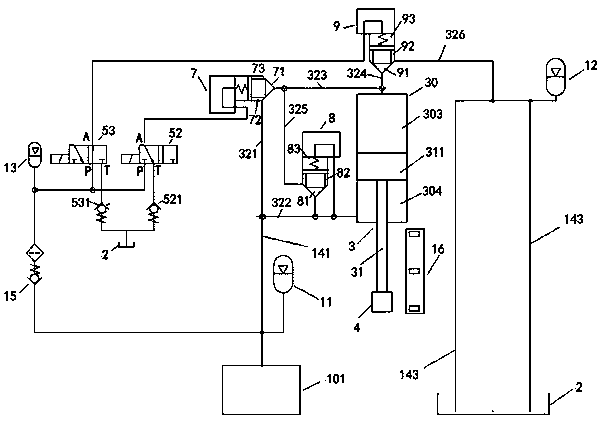

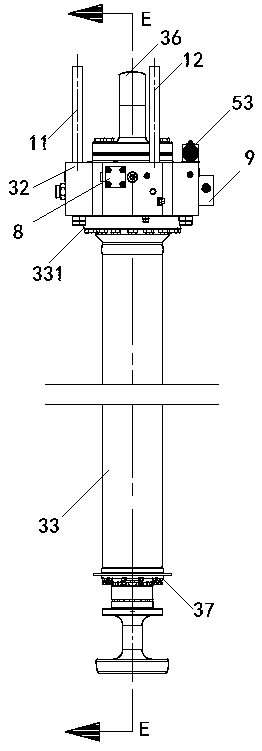

[0047] A hydraulic system of a hydraulic hammer, including a power source 101, an oil tank 2, a lifting cylinder 3, an impact hammer core 4, a second electromagnetic reversing valve 52, a third electromagnetic reversing valve 53, a second cartridge valve 7, a one-way Cartridge valve 8, third cartridge valve 9, second accumulator 11, third accumulator 12, fourth accumulator 13, second check valve 521, third check valve 531, fourth check valve To valve 15, high-pressure pipeline 141, low-pressure pipeline 143, travel switch 16 and control unit, lift cylinder 3 comprises the outer cylinder barrel 33 that contains upper end flange 331, inner cylinder barrel 30, piston rod 31, is positioned at outer cylinder barrel and The annular oil passage 35 between the inner cylinders, the upper hydraulic chamber 303 and the lower hydraulic chamber 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com