Construction method for detecting and treating karst cave through tunnel advance large pipe shed

A technology of advanced large pipe shed and construction method, which is applied in the construction field of tunnel advanced support measures, can solve problems such as increased engineering costs, casualties, and slowed down construction speed, so as to reduce the amount of reinforcement works, improve detection accuracy, reduce collapse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

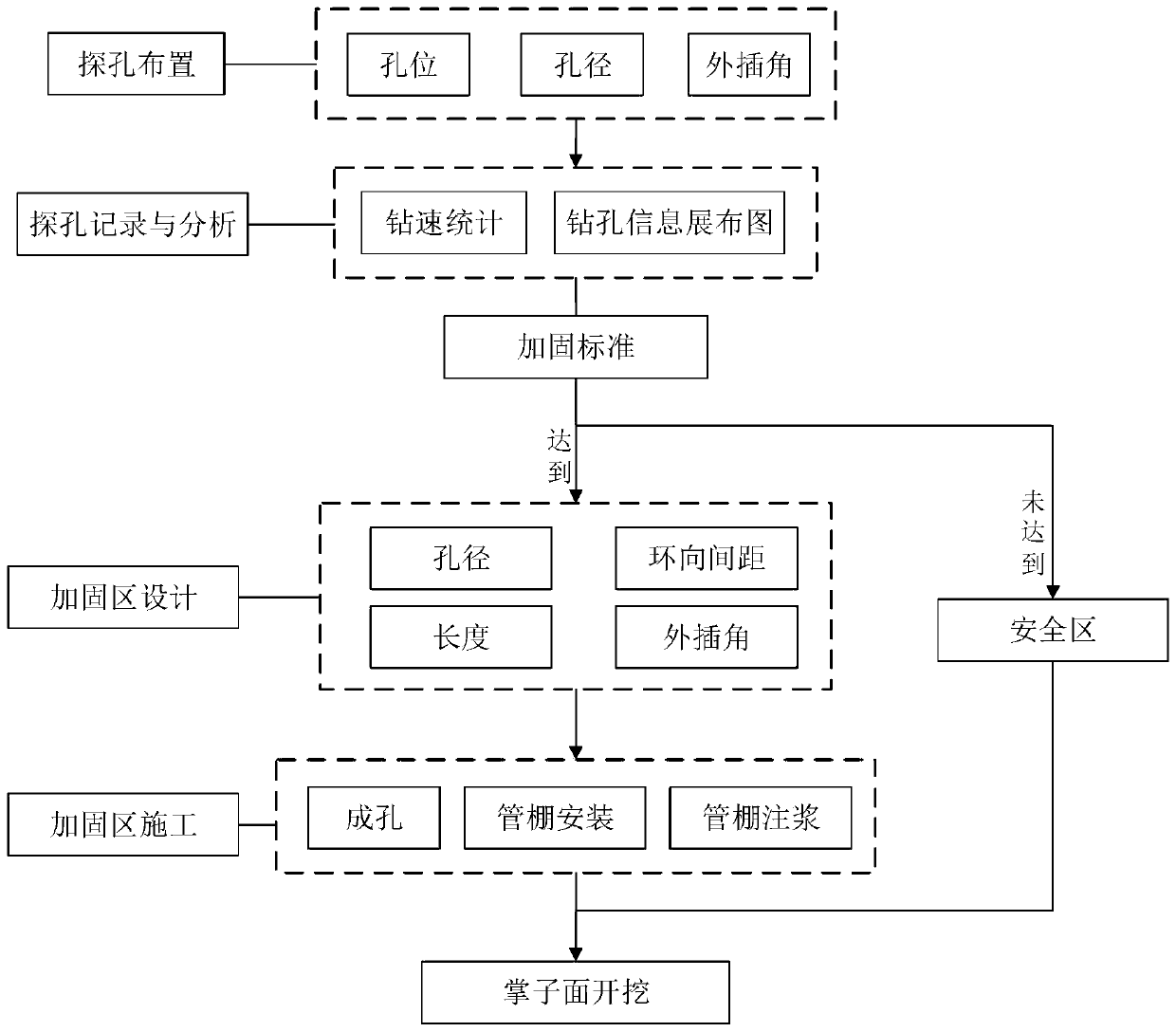

[0035] Embodiment one, such as figure 1 As shown, a construction method for detecting and treating karst caves in advance of large pipe sheds in tunnels, including the following steps:

[0036] (1) Combined with the results of geological exploration, pipe shed holes are drilled on the tunnel face. The pipe shed holes drilled include the detection holes drilled in the early stage and the reinforcement holes drilled in the later stage. For detection, the reinforcement holes are arranged on both sides of the detection hole for reinforcement, and the detection holes and reinforcement holes are arranged in the tunnel arch according to a predetermined arrangement.

[0037] (2) The detection hole and the reinforcement hole are all drilled forward along the excavation direction of the tunnel, and during the drilling process of the detection hole, the drilling speed of the drilling hole is recorded and the drilling information distribution map is drawn;

[0038] (3) Determine the scop...

Embodiment 2

[0052] Embodiment 2 is a three-lane and three-center-circle tunnel, and the outer contour span of the tunnel is about 17.0m. The implementation steps of the technical solution include:

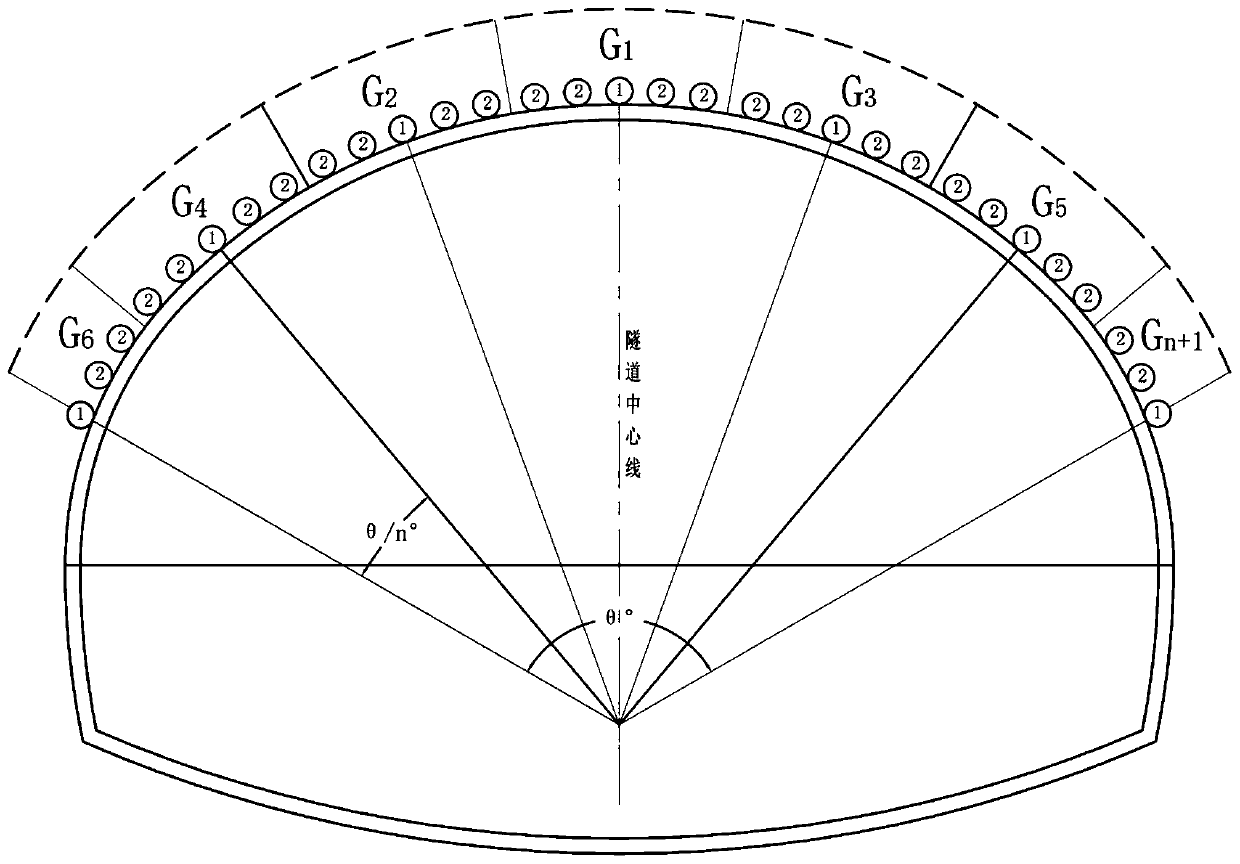

[0053] 1. Arrange 7 detection holes at 20° intervals in the 120° range of the arch. The detection hole diameter is 80mm, and the circumferential spacing of the detection holes is about 3.2m. Adjacent detection holes can find caves with a circumferential width greater than 3.2m. The 1.6m on both sides of each detection hole is used for partitioning, and the θ° range of the arch is divided into seven partitions: G1, G2...G7.

[0054] 2. The length of the detection hole is 30m, and the extrapolation angle is a 1 10-12° to ensure that caves with a height greater than 5m can be detected at the tail end.

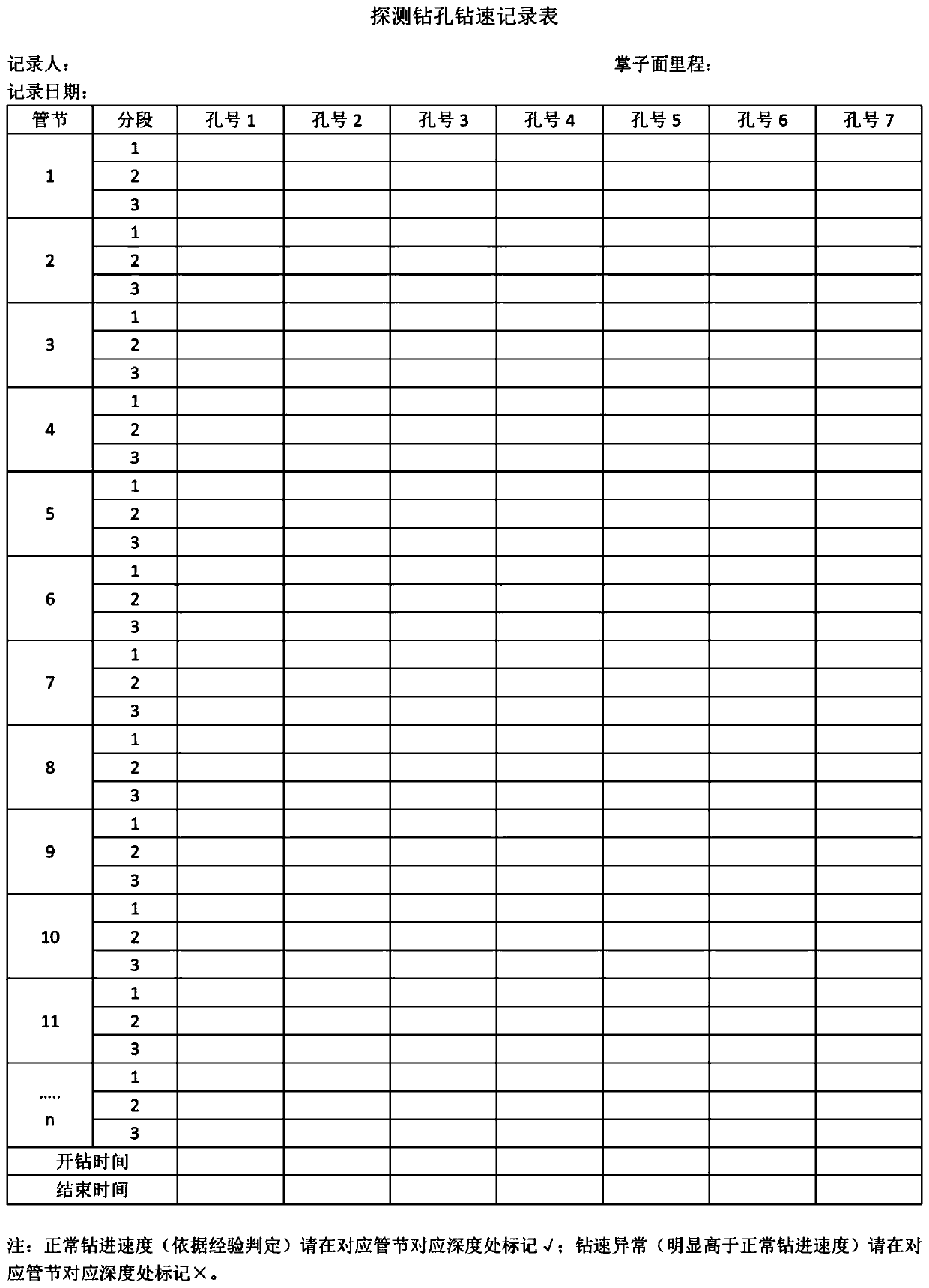

[0055] 3. Use the attached image 3 In the table, record the drilling speed during the drilling process of each detection hole, and use the attached Figure 4 The distribution map of the explor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com