Detachable circulation high-altitude large cantilever formwork and construction method thereof

A construction method and large overhang technology, applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of inability to reuse, waste of section steel, and difficulty, so as to save production costs and reduce materials , the effect of saving profiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

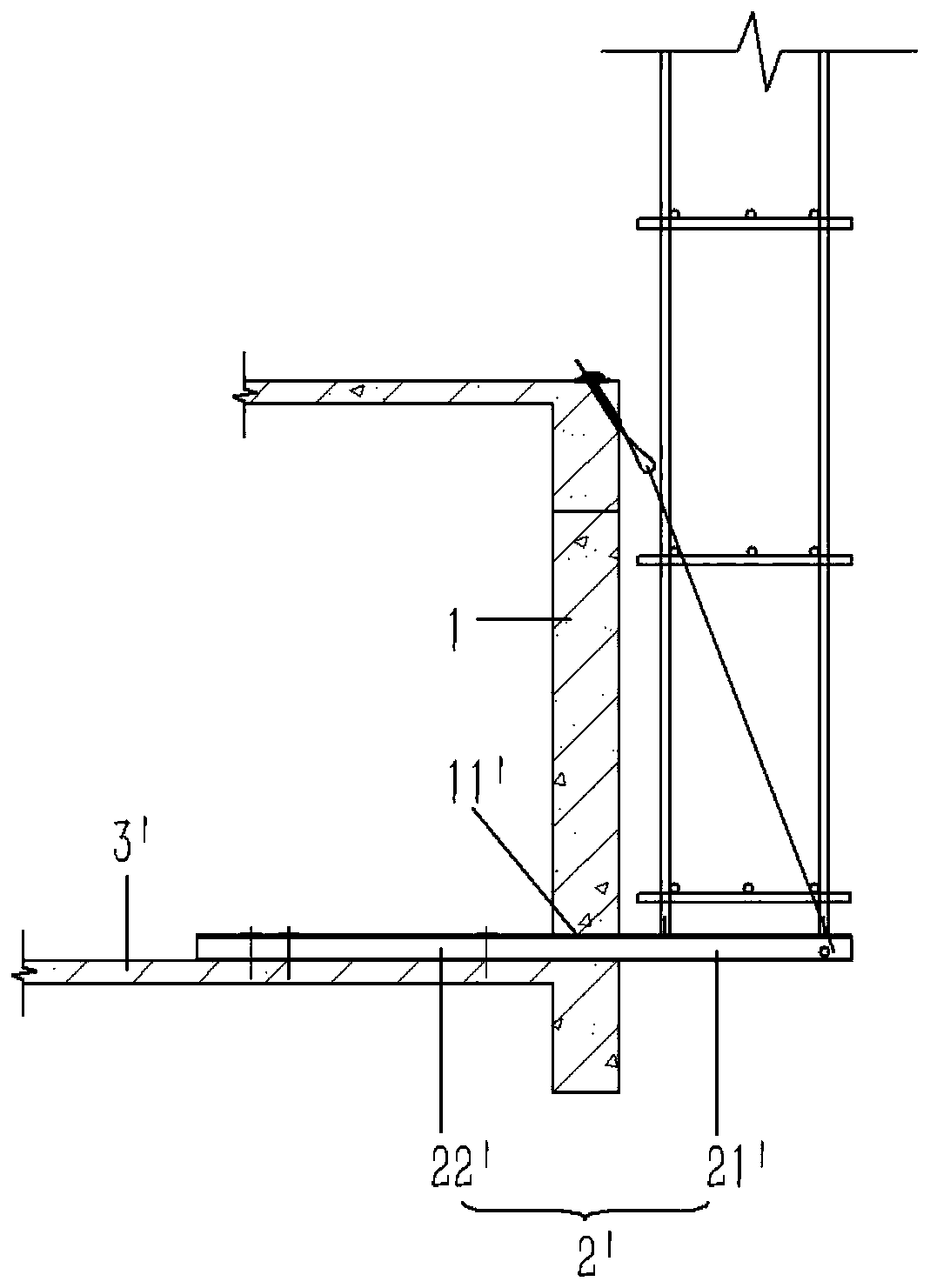

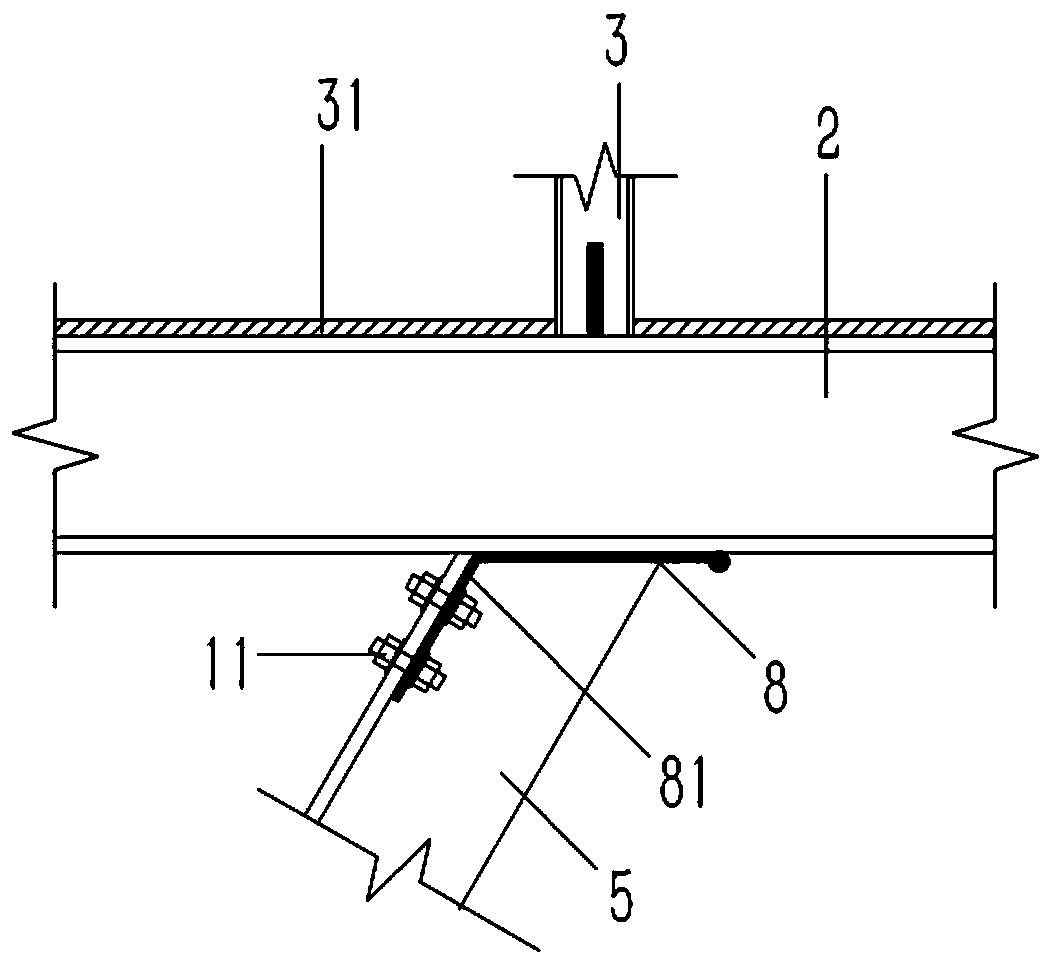

[0033] Example: see Figures 2 to 10 As shown, a detachable turnover high-altitude large cantilever formwork includes a shear wall 1 of a high-rise building. A number of bolts are embedded in the shear wall 1 to pass through pipes. Beam 2, the inner end of the cantilevered main beam 2 is welded and fixed with a vertical first end plate, and the first end plate is fixed on the shear wall 1 through a bolt assembly 11; the lower side of the cantilevered main beam 2 is provided with Diagonal bracing beam 5 and oblique connecting beam 6, the lower end surface of the cantilevered main girder 2 close to the outer end is welded and fixed with a first rib 8, the first rib 8 is bent and formed with a first oblique connecting plate 81, The first connecting plate 81 is fixedly connected to the lower end of the brace beam 5 through the bolt assembly 11; the lower end of the brace beam 5 is welded and fixed with a vertical second end plate, and the second end plate is fixed to the shear wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com