Maintenance method and structure from tail water tunnel access door slot to outlet tunnel section

A technology for repairing door slots and inspection gates, which is applied in the directions of hydropower generation, water conservancy projects, hydroelectric power stations, etc., can solve problems such as difficulty in maintenance of non-water retaining facilities, and achieve the effects of enhancing reliability, facilitating assembly and disassembly, and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

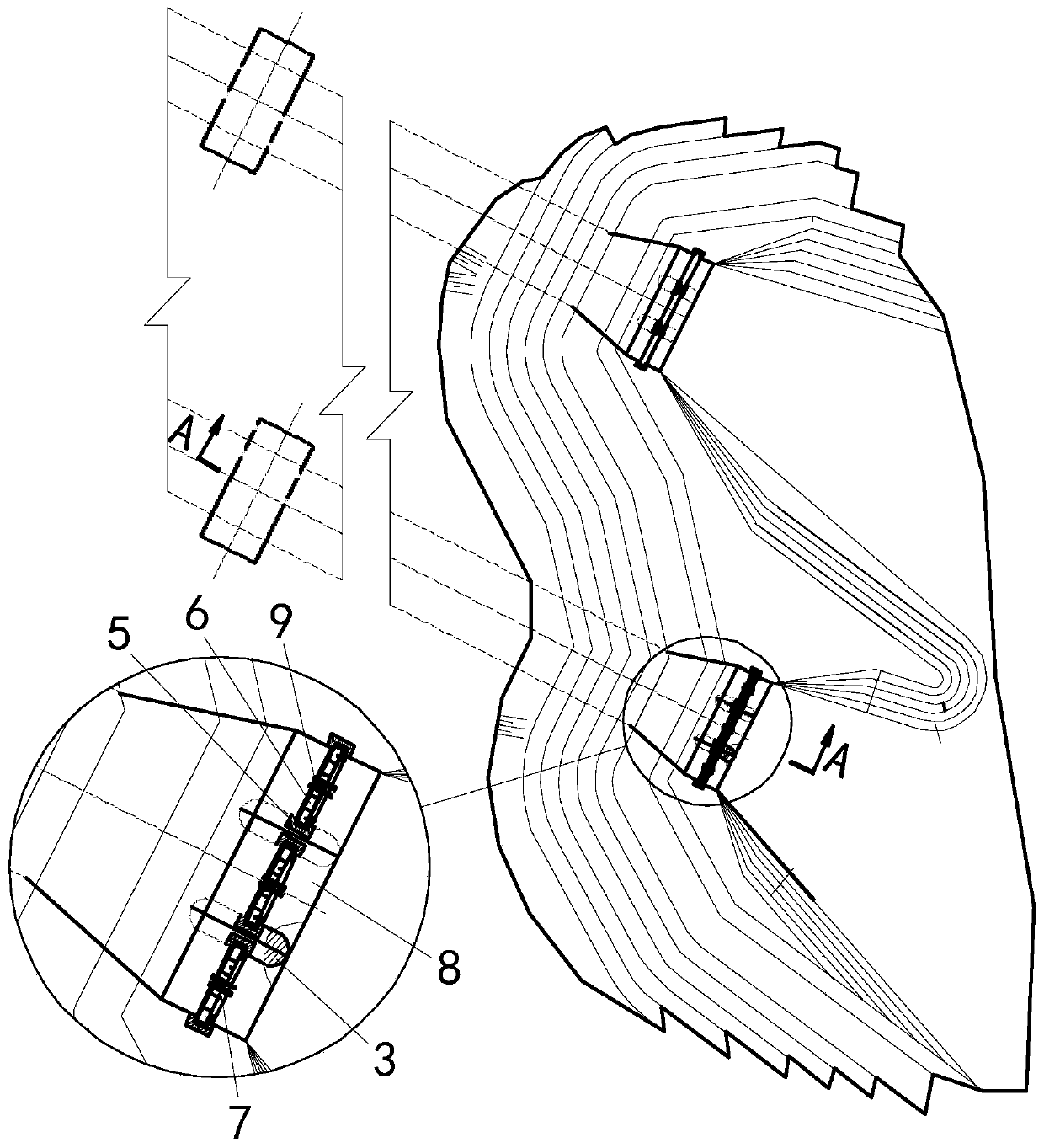

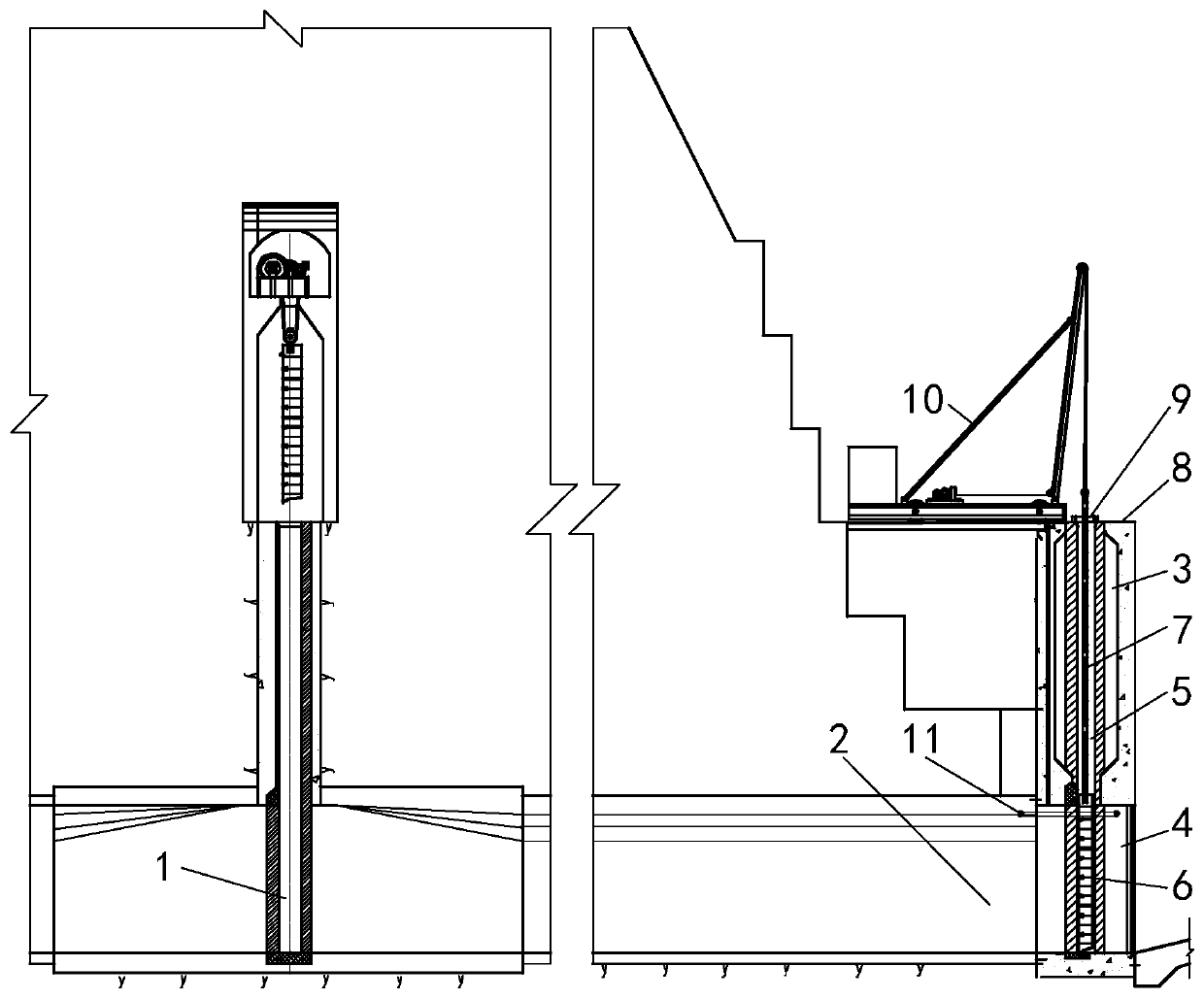

[0016] This example figure 1 with figure 2 shown. The tailwater outlet 2 behind the maintenance door slot 1 of the tailwater tunnel is partially enlarged and a set of longitudinal partitions 3 are arranged to divide the tailwater outlet into a plurality of sluice holes 4 outflow structures. A gate slot 5 is set in the gate hole 4; a maintenance gate 6 is set in the gate slot 5; the maintenance gate 6 is connected and locked to the locking beam 9 of the tail water outlet maintenance platform 8 by a pull rod 7; the maintenance gate 6 is opened and closed by a temporary crane 10; A bypass valve pipeline 11 is provided on both sides of the inspection gate 6 .

[0017] In the present invention, the section from the maintenance door slot of the tailrace tunnel to the exit tunnel adopts a multi-gate outflow structure in which the tailwater is partially expanded and the vertical pier is set. Multiple maintenance gates are installed inside to retain water to meet the maintenance re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com