Spunlaced nonwoven fabric production technology and application thereof

A non-woven fabric and production process technology, applied in the field of non-woven fabrics, can solve the problems of heavy weight, uneven fluffing surface, affecting the safety of use and skin-friendly feeling, and achieve the effect of improving strength, smooth surface, and not easy to pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

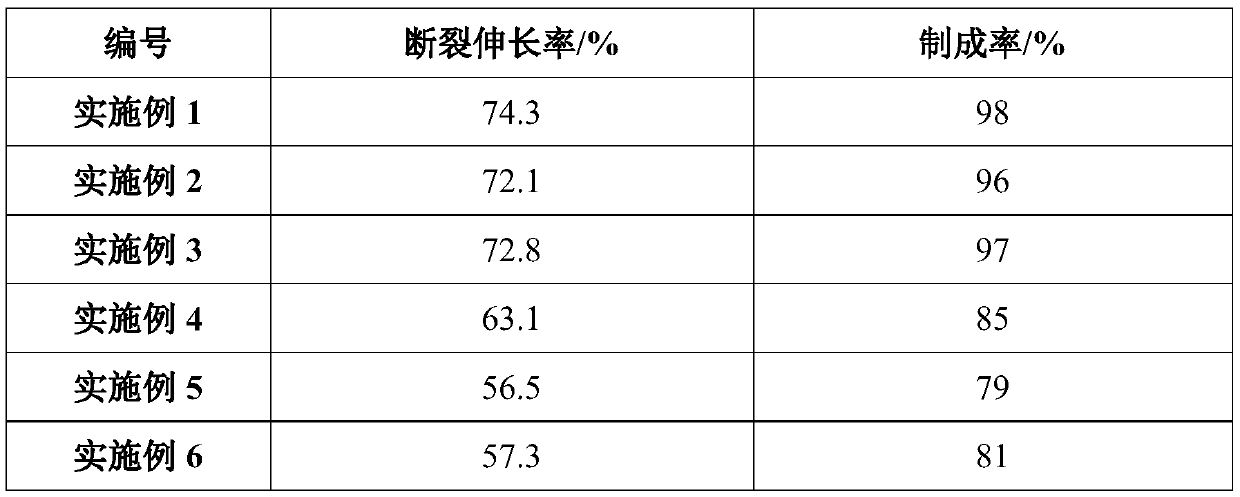

Examples

Embodiment 1

[0045] The present embodiment provides a production process for spunlace nonwovens, comprising the following steps:

[0046] S1: The viscose fiber and polyester are weighed according to the mass ratio of 1:1 and then put into the screen conveyor, then the coarse opening and mixing are carried out by the coarse opening device, and then sent to the fine opening device for fine opening and mixing, and then Send to the cotton storage box and mix thoroughly;

[0047] S2: The fibers after opening and mixing in S1 are sent to the air pressure cotton box, processed into a uniform cotton feast and output, and then carded into a web, cross-lapped, and drawn to obtain a forming fiber web; The stretch ratio is 3.0.

[0048] S3: Pre-wet the formed fiber web in S2; the pre-wet treatment adopts a double-mesh clamping type, the number of lower meshes is 70 meshes, the number of upper meshes is 40 meshes, and the water pressure is 10KG.

[0049] S4: The formed fiber web pre-wetted in S3 is s...

Embodiment 2

[0052] The present embodiment provides a production process for spunlace nonwovens, comprising the following steps:

[0053] S1: The viscose fiber and polyester are weighed according to the weight ratio of 2:1 and then put into the screen conveyor, and then the coarse opening and mixing are carried out by the coarse opening device, and then sent to the fine opening device for fine opening and mixing, and then Send to the cotton storage box and mix thoroughly;

[0054] S2: The fibers after opening and mixing in S1 are sent to the air pressure cotton box, processed into a uniform cotton feast and output, and then carded into a web, cross-lapped, and drawn to obtain a forming fiber web; The stretch ratio is 3.0.

[0055] S3: Pre-wet the formed fiber web in S2; the pre-wet treatment adopts a double-mesh clamping type, the number of lower meshes is 70 meshes, the number of upper meshes is 40 meshes, and the water pressure is 10KG.

[0056] S4: The formed fiber web pre-wetted in S...

Embodiment 3

[0059] The present embodiment provides a production process for spunlace nonwovens, comprising the following steps:

[0060] S1: The viscose fiber is weighed and put into the net conveying curtain, then the coarse opening and mixing are carried out by the coarse opening device, and then sent to the fine opening device for fine opening and mixing, and then sent to the cotton storage box for full mixing ;

[0061] S2: The fibers after opening and mixing in S1 are sent to the air pressure cotton box, processed into a uniform cotton feast and output, and then carded into a web, cross-lapped, and drawn to obtain a forming fiber web; The stretch ratio is 3.0.

[0062] S3: Pre-wet the formed fiber web in S2; the pre-wet treatment adopts a double-mesh clamping type, the number of lower meshes is 70 meshes, the number of upper meshes is 40 meshes, and the water pressure is 10KG.

[0063] S4: The formed fiber web pre-wetted in S3 is sent to the spunlace area for reinforcement treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com