Smokeless sulfur-free magenta indoor setting-off type cold firework agent and preparation method thereof

A cold fireworks and discharge type technology, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve problems such as environmental pollution, audience disgust, impact on human health, etc., and achieves simple process, few steps, and significant economic and social benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

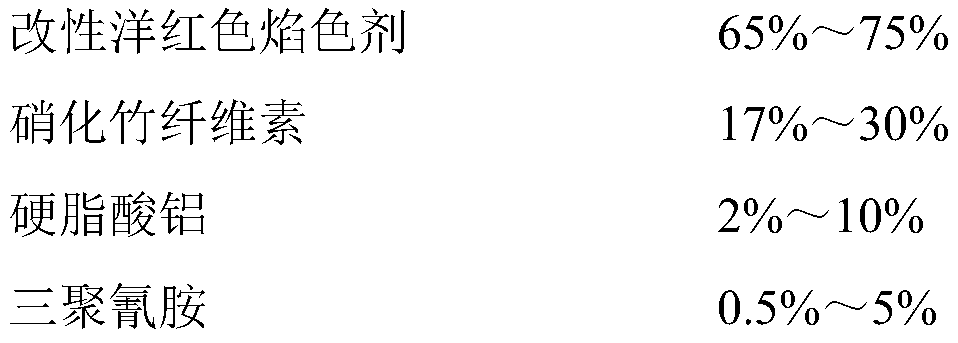

[0036] A kind of smokeless and sulfur-free magenta indoor discharge type cold smoke flower agent, its components and their mass percentages are as follows:

[0037]

[0038] The nitrogen content of the nitrobamboo cellulose in the components is 12% to 12.5%;

[0039] Add 200g of nitrobamboo cellulose to 1000g of ethyl acetate, stir the above mixed solution at a rate of 60rpm, add 70g of aluminum stearate and 30g of melamine under stirring, and stir for 30 minutes to prepare solution A;

[0040] Use a steel brush to remove the oxide layer on the surface of the zirconium ingot, place the zirconium ingot in an ultrasonic cleaner, and clean it with absolute ethanol. After cleaning for 15 minutes, place the zirconium ingot at 40°C for 5 minutes in vacuum, and then Weigh 160g of zirconium ingot; place 160g of zirconium ingot, 290g of light producing agent and 350g of light aid on the bottom of the crucible of the vacuum induction furnace, seal the vacuum induction furnace, turn o...

Embodiment 2

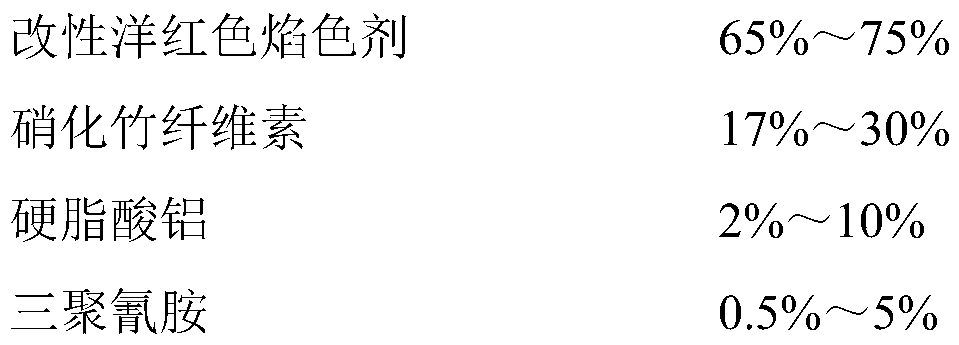

[0050] A kind of smokeless and sulfur-free magenta indoor discharge type cold smoke flower agent, its components and their mass percentages are as follows:

[0051]

[0052] The nitrogen content of the nitrobamboo cellulose in the components is 12% to 12.5%;

[0053] Add 1.7kg of nitrobamboo cellulose to 10.2kg of ethyl acetate, stir the above mixed solution at a rate of 70rpm, add 0.5kg of aluminum stearate and 0.3kg of melamine under stirring, and stir for 30 minutes to obtain Solution A;

[0054] Use a steel brush to remove the oxide layer on the surface of the zirconium ingot, place the zirconium ingot in an ultrasonic cleaner, and clean it with absolute ethanol. After cleaning for 15 minutes, place the zirconium ingot at 40°C for 5 minutes in vacuum, and then Weigh 1.7kg of zirconium ingot; place 1.7kg of zirconium ingot, 3.6kg of luminescence agent and 3.2kg of light aid on the bottom of the crucible of the vacuum induction furnace, seal the vacuum induction furnace,...

Embodiment 3

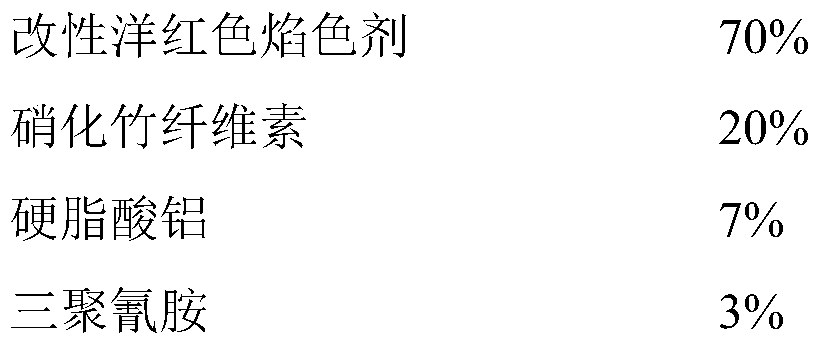

[0064] A kind of smokeless and sulfur-free magenta indoor discharge type cold smoke flower agent, its components and their mass percentages are as follows:

[0065]

[0066] The nitrogen content of the nitrobamboo cellulose in the components is 12% to 12.5%;

[0067] Add 2.5kg of nitrobamboo cellulose to 13kg of ethyl acetate, stir the above mixed solution at a rate of 100rpm, add 0.5kg of aluminum stearate and 0.5kg of melamine under stirring, and stir for 40 minutes to obtain a solution A;

[0068] Use a steel brush to remove the oxide layer on the surface of the titanium ingot, place the titanium ingot in an ultrasonic cleaner, and clean it with absolute ethanol. After cleaning for 15 minutes, place the titanium ingot at 40°C for 5 minutes in vacuum, and then Weigh 1.8kg of titanium ingot; place 1.8kg of titanium ingot, 3.6kg of luminescence agent and 1.8kg of light aid on the bottom of the crucible of the vacuum induction furnace, seal the vacuum induction furnace, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com