Method for purifying sodium bromide by utilizing waste circuit board pyrolysis coke

A technology for waste circuit boards and sodium bromide is applied in the field of crude bromide salts to achieve the effects of simple and easy process, environmental friendliness and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

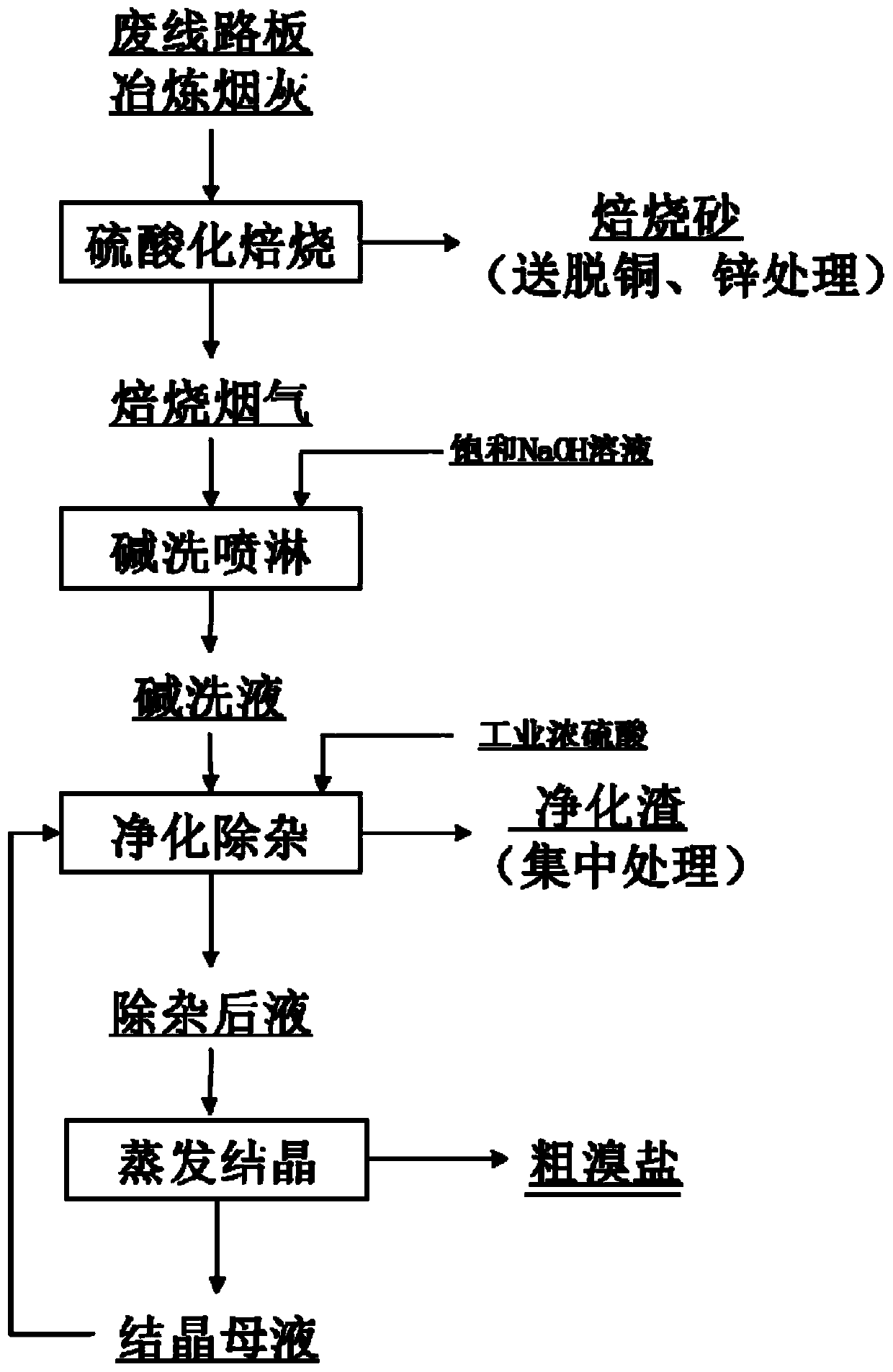

Method used

Image

Examples

Embodiment 1

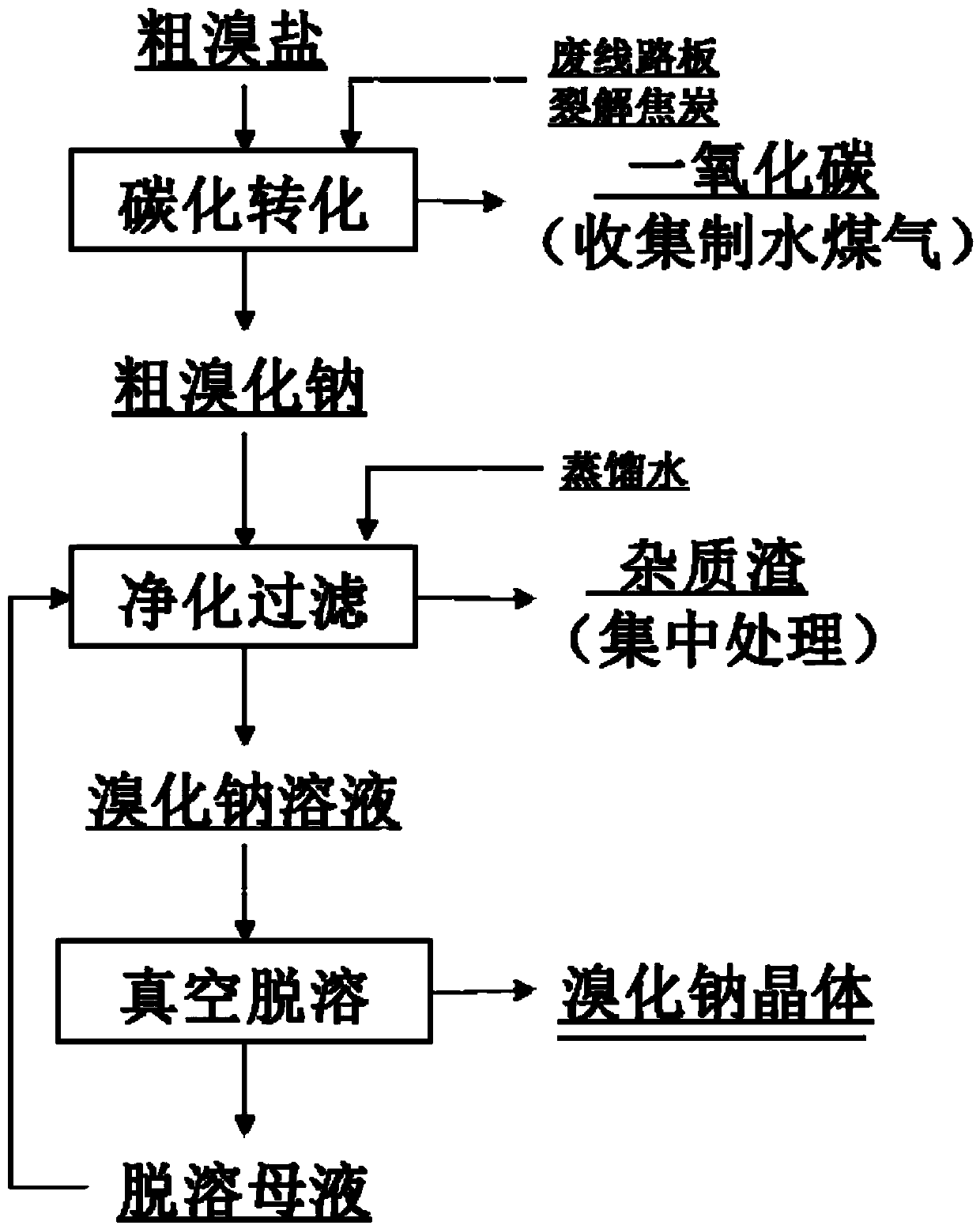

[0019] Follow the steps below to recycle:

[0020] (1) Carbonization conversion: mix the crude bromine salt enriched from waste circuit board smelting soot with the coke separated from the waste circuit board pyrolysis slag, mix evenly and heat the reaction to obtain carbon monoxide and crude sodium bromide, carbon monoxide Collect raw materials for making water gas, wherein the mass of coke added per kilogram of crude bromine salt is 0.1kg, the reaction temperature is 250°C, and the reaction time is 1.0h;

[0021] (2) Purification and filtration: the thick sodium bromide obtained in step (1) is added into distilled water for purification and filtration to obtain impurity slag and sodium bromide solution, and the impurity slag is treated centrally, wherein the liquid-solid volume mass ratio is 8:1 (liter / kg), the reaction temperature is 50°C, and the reaction time is 20min;

[0022] (3) vacuum precipitating: the sodium bromide solution that step (2) obtains is carried out va...

Embodiment 2

[0025] Follow the steps below to recycle:

[0026] (1) Carbonization conversion: mix the crude bromine salt enriched from waste circuit board smelting soot with the coke separated from the waste circuit board pyrolysis slag, mix evenly and heat the reaction to obtain carbon monoxide and crude sodium bromide, carbon monoxide Collect raw materials for making water gas, wherein the mass of coke added per kilogram of crude bromine salt is 1.0 kg, the reaction temperature is 450 ° C, and the reaction time is 2.0 h;

[0027] (2) Purification and filtration: the thick sodium bromide obtained in step (1) is added into distilled water for purification and filtration to obtain impurity slag and sodium bromide solution, and the impurity slag is treated centrally, wherein the liquid-solid volume mass ratio is 3:1 (liter / kg), the reaction temperature is 80°C, and the reaction time is 60min;

[0028] (3) vacuum precipitating: the sodium bromide solution that step (2) obtains is carried ou...

Embodiment 3

[0031] Follow the steps below to recycle:

[0032] (1) Carbonization conversion: mix the crude bromine salt enriched from waste circuit board smelting soot with the coke separated from the waste circuit board pyrolysis slag, mix evenly and heat the reaction to obtain carbon monoxide and crude sodium bromide, carbon monoxide Collect raw materials for making water gas, wherein the mass of coke added per kilogram of crude bromine salt is 0.4 kg, the reaction temperature is 300°C, and the reaction time is 1.2h;

[0033] (2) purification filtration: the thick sodium bromide that step (1) obtains is added distilled water and carry out purification filtration, obtain impurity slag and sodium bromide solution, impurity slag centralized treatment, wherein liquid-solid volume mass ratio is 7: 1 (liter / kg), the reaction temperature is 60°C, and the reaction time is 25min;

[0034] (3) vacuum precipitating: the sodium bromide solution that step (2) obtains is carried out vacuum precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com