Working method of intelligent storing system

A working method and intelligent warehousing technology, applied in the field of robotics, can solve the problems of low fault tolerance rate of robots, failure to deal with problems in time, and no contact with robots, etc., to achieve improved orderliness, simple structure, and improved access convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

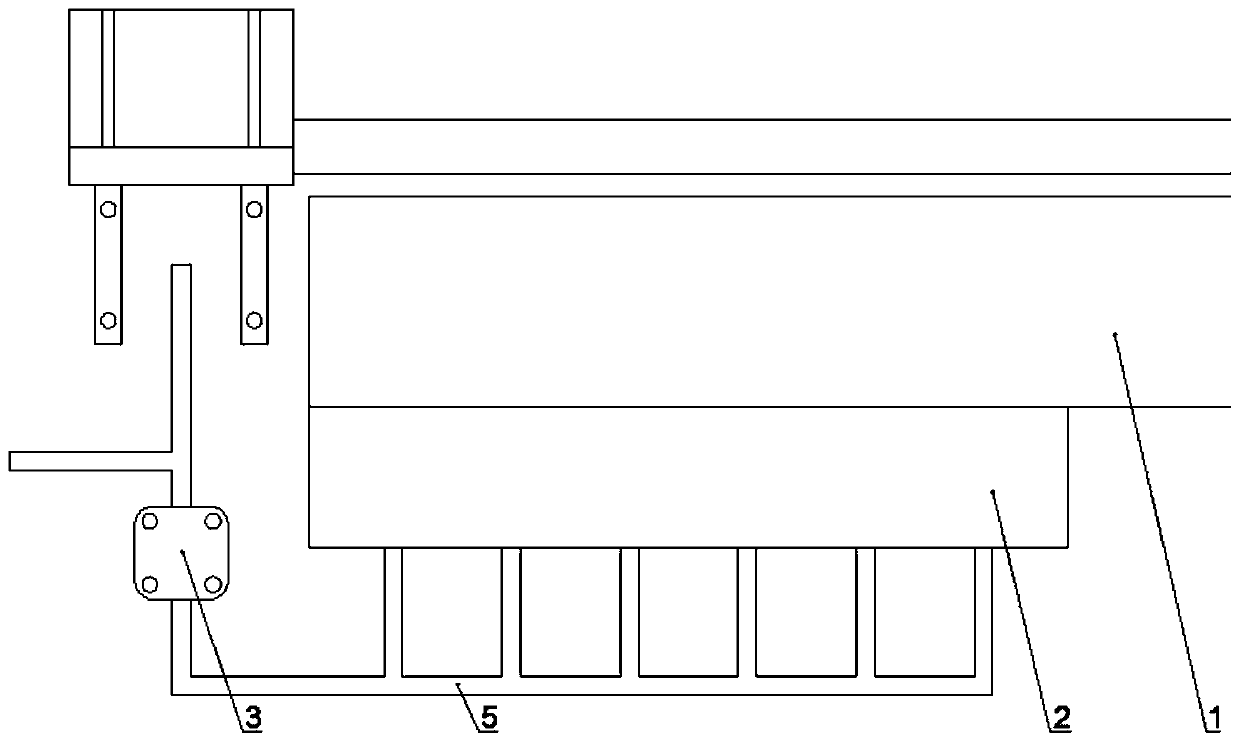

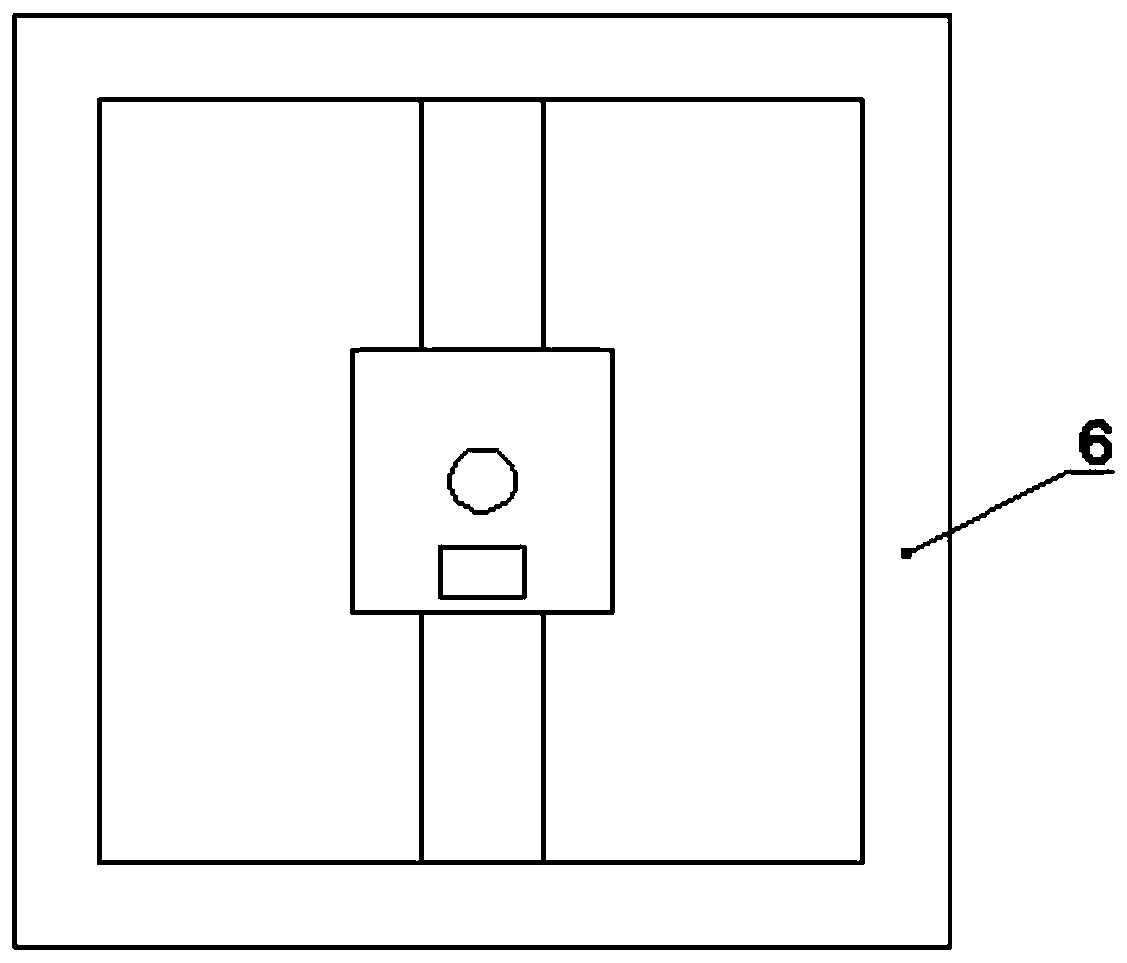

[0048] like Figure 1-11 The working method of an intelligent storage system shown is characterized in that it includes: a storage bin 1, a standby bin 2, a material transport robot 3, a beacon storage box 4, a road sign 5 and a position beacon 6, and the storage bin 1 is provided with a beacon storage box 4, the bottom of the storage compartment 1 is provided with a standby compartment 2, and the standby compartment 2 is provided with a delivery robot 3, and the delivery robot 3 is provided with multiple, the storage compartment 1 is surrounded by road signs 5, the road signs 5 are set on the ground, there are multiple position beacons 6, and the position beacons 6 are placed in various parts of the workshop. Messenger;

[0049] The working method of the above-mentioned intelligent storage system includes discharging and recycling, which specifically includes the following steps:

[0050] Step 1: discharging, turn on the position beacon 6 and place it on the ground, the pos...

Embodiment 2

[0064] like Figure 1-6 The working method of an intelligent storage system shown is characterized in that it includes: a storage bin 1, a standby bin 2, a material transport robot 3, a beacon storage box 4, a road sign 5 and a position beacon 6, and the storage bin 1 is provided with a beacon storage box 4, the bottom of the storage compartment 1 is provided with a standby compartment 2, and the standby compartment 2 is provided with a delivery robot 3, and the delivery robot 3 is provided with multiple, the storage compartment 1 is surrounded by road signs 5, the road signs 5 are set on the ground, there are multiple position beacons 6, and the position beacons 6 are placed in various parts of the workshop. Messenger;

[0065] The working method of the above-mentioned intelligent storage system includes discharging and recycling, which specifically includes the following steps:

[0066] Step 1: discharging, turn on the position beacon 6 and place it on the ground, the posi...

Embodiment 3

[0072] like figure 1 , 2 A working method of an intelligent storage system shown in , 3 and 7 is characterized in that it includes: a storage bin 1, a standby bin 2, a material delivery robot 3, a beacon storage box 4, a road sign 5 and a position beacon 6, The storage compartment 1 is provided with a beacon storage box 4, the bottom of the storage compartment 1 is provided with a standby compartment 2, and the standby compartment 2 is provided with a delivery robot 3, and the delivery robot 3 is provided with multiple, Said storage compartment 1 is provided with road signs 5 around, said road signs 5 are arranged on the ground, said position beacons 6 are provided with a plurality of, said position beacons 6 are placed in various parts of the workshop, said position beacons 6 is essentially a transmitter;

[0073] The working method of the above-mentioned intelligent storage system includes discharging and recycling, which specifically includes the following steps:

[0074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com