Wood packaging box convenient to move

A packaging box and driving device technology, applied in the direction of external accessories, etc., can solve the problems of inconvenient movement, large overall weight, difficult movement of wooden packaging boxes, etc., and achieve the effects of easy movement, improved support stability, and reduced movement difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

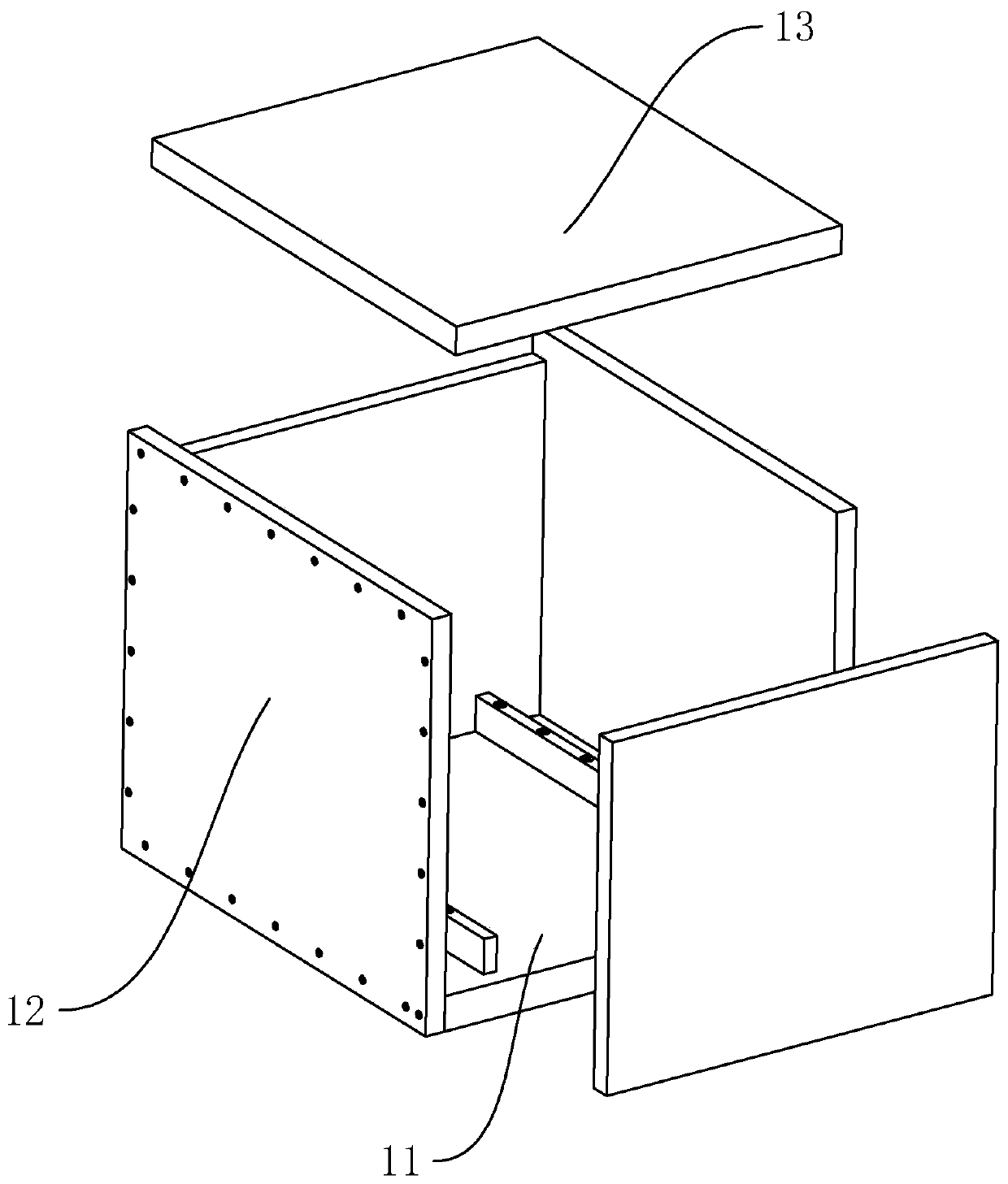

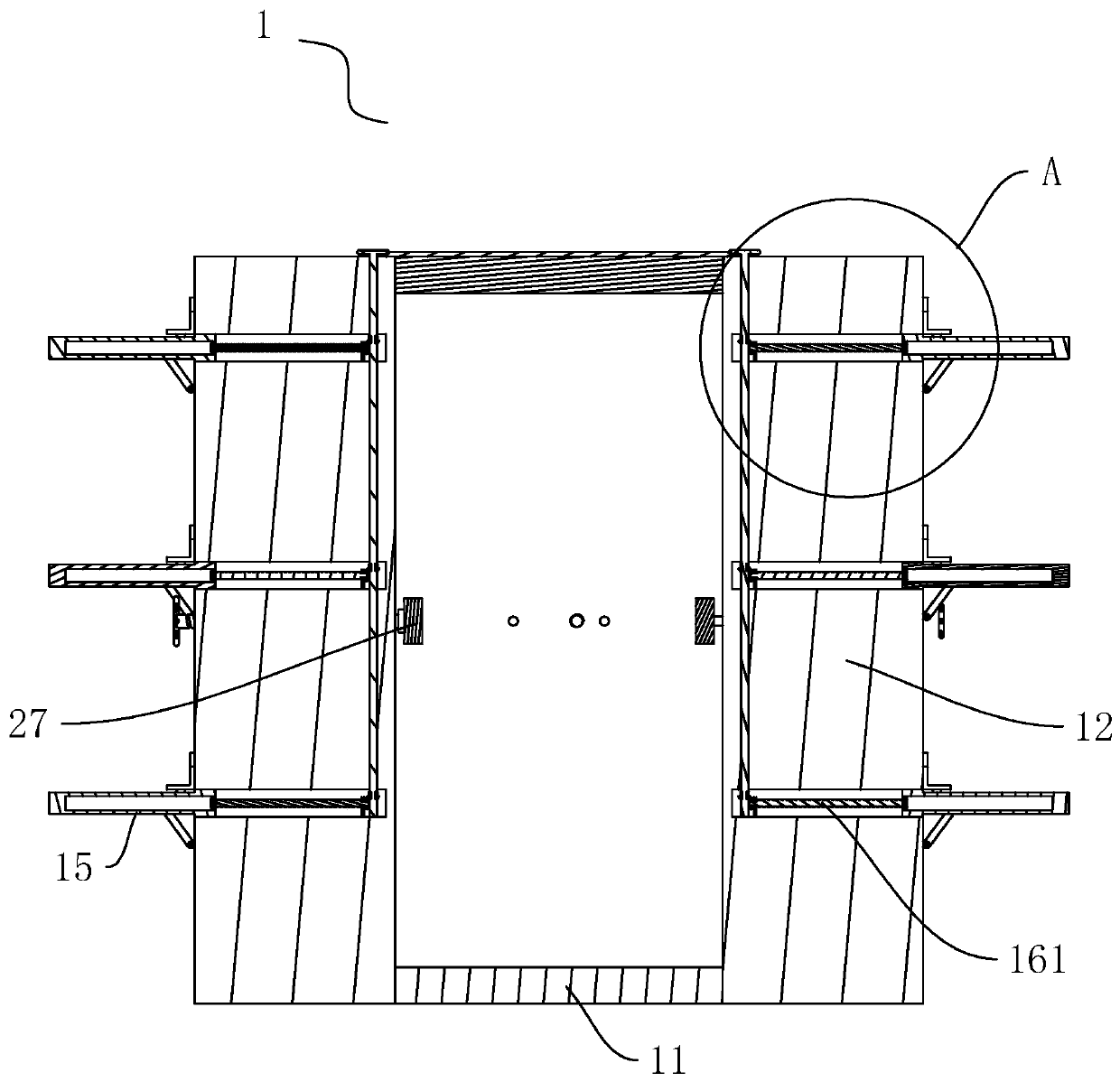

[0040] A kind of wooden packing box with good protection effect, refer to figure 2 and image 3 , including a box body 1, the box body 1 includes a support pallet 11, a side plate 12 and a top plate 13 arranged on the support pallet 11, wherein the side plate 12 is integrally formed.

[0041] refer to figure 2 and image 3 , Each side plate 12 is provided with three strip-shaped installation grooves 2 along the horizontal direction, and adjacent strip-shaped installation grooves 2 are arranged in parallel. The inner chamber of the strip-shaped installation groove 2 is arranged in a rectangular shape, and the strip-shaped installation grooves 2 on adjacent side plates 12 that conflict with each other are located at different levels.

[0042] refer to figure 2 and image 3, a sliding block 3 is slidably connected to the bar-shaped mounting groove 2, and the sliding block 3 is arranged in a cuboid shape.

[0043] refer to Figure 4 and Figure 5 , The upper and lower s...

Embodiment 2

[0060] A kind of wooden packing box with good protection effect, refer to Figure 9 , the difference from Embodiment 1 is that the driving device 16 includes a rack 163 that is slidably connected in the bar-shaped mounting groove 2 (refer to Figure 8 ), rotatably connected to the gear 164 in the bar-shaped mounting groove 2 and rotatably meshed with the rack 163 . Wherein, the side plate 12 is rotatably connected with a driving rod 2 31 , and the driving rod 2 31 is arranged along a direction parallel to the surface of the side plate 12 and connects through three strip-shaped installation grooves 2 on the same side plate 12 . The top of the driving rod 2 31 protrudes from the upper surface rack 163 of the side plate 12 and is arranged along the direction perpendicular to the surface of the side plate 12, and the side plate 12 is fixedly connected with a rotating handle 2 33 for driving the rod.

[0061] The specific implementation process: when the sliding block 3 needs to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com