Archaized brick packaging process

A packaging technology, antique brick technology, applied in the field of ceramic manufacturing, can solve the problems of antique brick surface offset printing, high product use cost, thinning, etc., and achieve the effect of efficient packaging, efficient film packaging, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

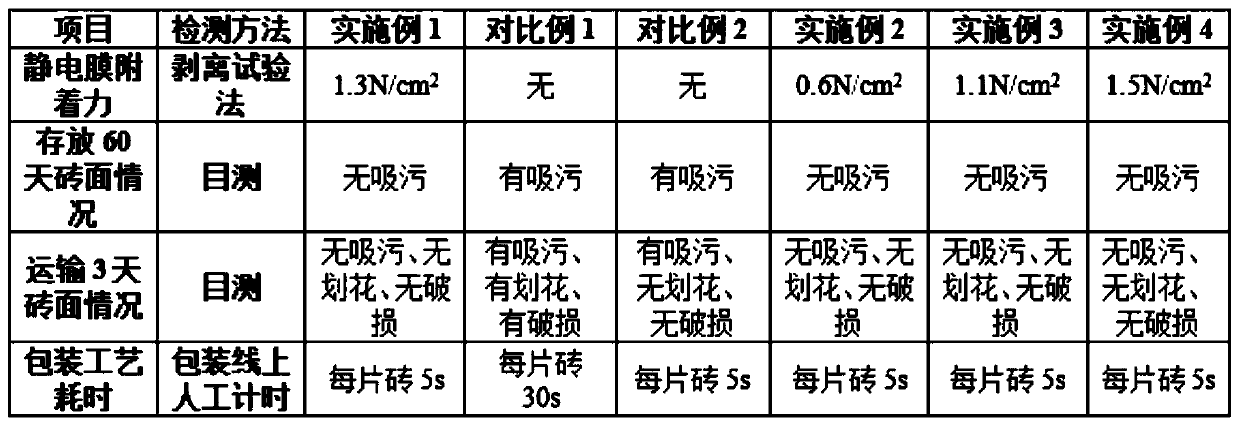

Examples

Embodiment 1

[0018] An antique brick packaging process, the brick surface area is 60 × 60cm, which specifically includes the following steps:

[0019] 1) Use a wet sponge to wipe water on the rough brick surface of the finished antique brick product conveyed by the conveyor belt. The area of the wet sponge to wipe water is the area of the brick surface of the antique brick, and the brick surface brightness of the finished antique brick is controlled to be 6 degrees. The transmission speed of the conveyor belt is 25 pieces / min, and a water film is formed on the surface of the finished antique brick, and the water content of the water film is controlled to be 5g, so that the finished antique brick with the water film is obtained;

[0020] 2) Cover the surface of the antique brick finished product with a water film with an electrostatic film with a thickness of 0.02 mm by means of film pasting equipment to form an antique brick finished product covered with an electrostatic film. After sta...

Embodiment 2

[0025] An antique brick packaging process, the brick surface area is 80 × 80cm, specifically including the following steps:

[0026] 1) Use a wet sponge to wipe water on the rough brick surface of the finished antique brick product conveyed by the conveyor belt. The area of the wet sponge wiped water is the area of the brick surface of the antique brick, and the brick surface brightness of the finished antique brick is controlled to be 12 degrees. The transmission speed of the conveyor belt is 20 pieces / min, and a water film is formed on the surface of the finished antique brick, and the water content of the water film is controlled to be 2g, so that the finished antique brick with the water film is obtained;

[0027] 2) Through film pasting equipment, an electrostatic film with a thickness of 0.04mm is covered on the surface of the antique brick finished product with a water film to form an antique brick finished product covered with an electrostatic film. After stacking a...

Embodiment 3

[0029] An antique brick packaging process, the brick surface area is 60 × 60cm, which specifically includes the following steps:

[0030] 1) Use a wet sponge to wipe water on the rough brick surface of the antique brick finished product conveyed by the conveyor belt. The area of the wet sponge wiped water is the brick surface area of the antique brick, and the brick surface brightness of the finished antique brick is controlled to be 8 degrees. The transmission speed of the conveyor belt is 40 pieces / min, and a water film is formed on the surface of the finished antique brick, and the water content of the water film is controlled to be 3g, so that the finished antique brick with the water film is obtained;

[0031] 2) Through film pasting equipment, an electrostatic film with a thickness of 0.03 mm is covered on the surface of the antique brick finished product with a water film to form an antique brick finished product covered with an electrostatic film. After stacking and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com