Manufacturing method of light heat insulation sheet

A manufacturing method, lightweight heat insulation technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problem of repeated steps of heat shields, heavy weight of heat shields, and poor heat insulation effect And other problems, to achieve good heat insulation effect, improve durability, good protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

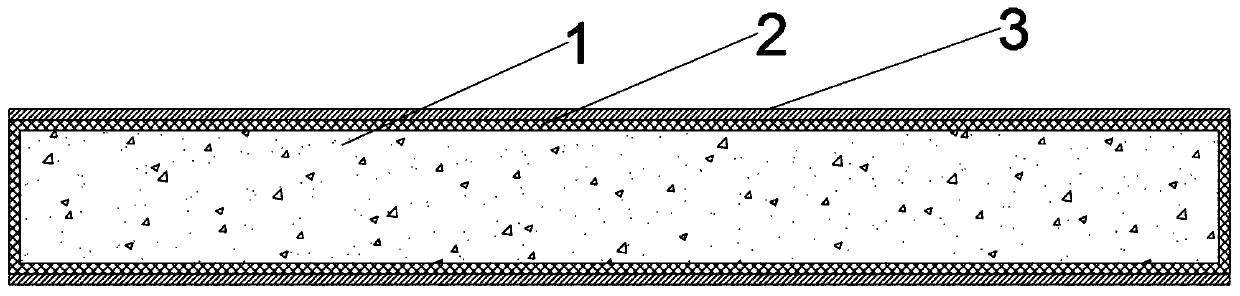

[0018] Such as figure 1 Shown, a kind of manufacturing method of light-weight thermal insulation sheet comprises the manufacturing method and combination method thereof of airgel inner bag 1, porous composite layer 2 and ceramic protective layer 3 respectively;

[0019] The airgel inner bag 1 is the innermost layer of the heat insulation sheet, which is made of silica airgel felt by cutting;

[0020] The porous composite layer 2 is arranged on the outside of the airgel inner bag 1, and it is made of a porous composite material; the manufacturing method of the porous composite material is as follows:

[0021] 1: Weigh 5-15 parts of silica airgel powder, 8-24 parts of porous substrate and 1-5 parts of hot melt adhesive according to the weight ratio;

[0022] 2: Wrap the porous substrate on the surface of the airgel inner capsule 1;

[0023] 3: Thermally spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com