A high-efficiency dust collection and grinding workbench

A technology for workbenches and workbenches, which is applied in the direction of manufacturing tools, grinding racks, and grinding beds, etc., can solve the problems of low dust collection rate, high energy consumption of workbenches, increased suffering from pneumoconiosis, etc., and achieves improvement Effects of working environment, reducing energy consumption, and protecting occupational health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

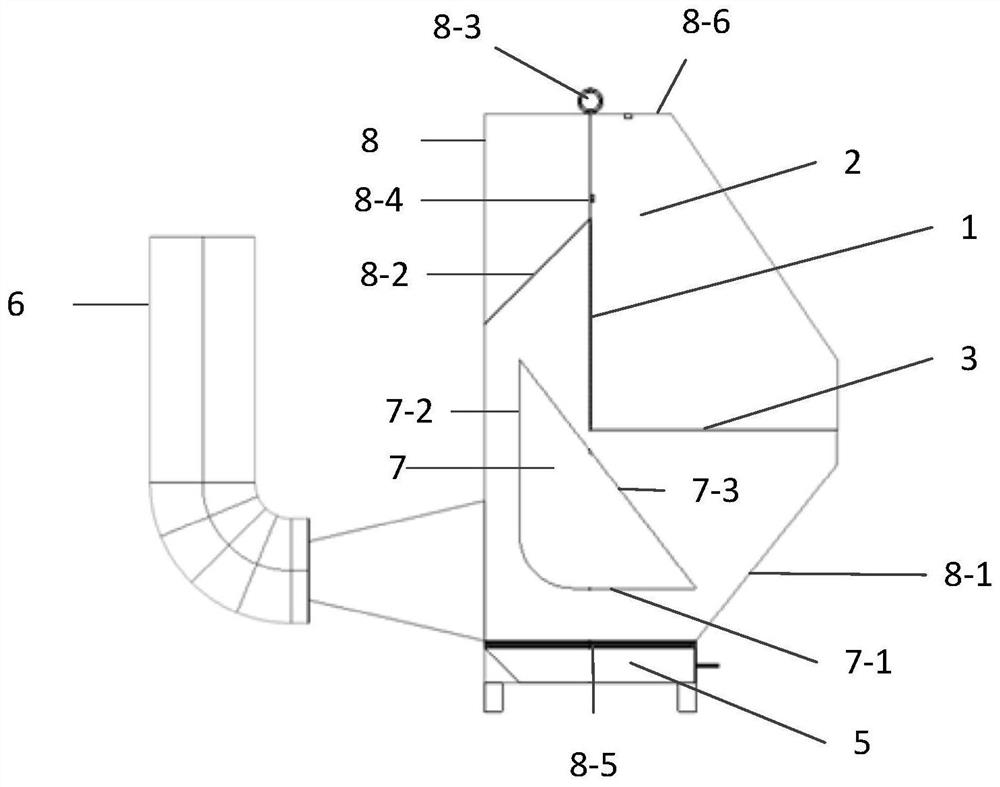

[0019] A high-efficiency dust-collecting and grinding workbench, which consists of a backboard (1), a baffle (2), a worktable (3), a human body sensor (4), a dust collection drawer (5), and an air duct (6 ), a built-in rectification structure (7), an equipment casing (8), and an illuminating lamp (9). The backboard (1) and the working surface (3) are both porous orifice plates with a hole diameter of 10 mm and a hole spacing of 10 mm. The working surface is composed of a lower stainless steel porous orifice plate and an upper rubber porous orifice plate. , and hole-to-hole installation, the back plate (1) is fixed on the equipment casing (8) by screws, the work surface (3) is embedded in the equipment casing (8), and baffles (2) are set on both sides of the work surface (3) ), the baffle realizes opening and closing through the hinge, and a fixing device is set on the equipment casing.

[0020] A vertical section of 100mm is set between the working surface (3) and the front r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com