Lifting and rotating device for horizontal cam exchange table

A technology of lifting, rotating and exchanging tables, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of limiting operation efficiency and slow driving speed of hydraulic lifting, and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention. The components in the structures in the drawings of the embodiments are not scaled according to the normal scale, so they do not represent the actual relative sizes of the structures in the embodiments. The above or upper side of the structure or surface includes the case where there are other layers in the middle.

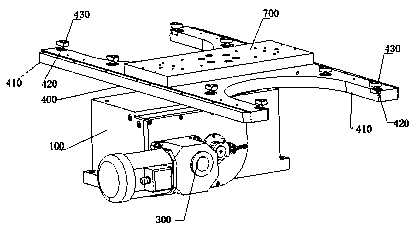

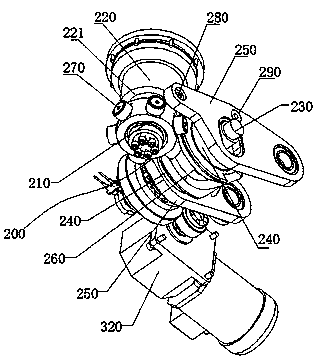

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7As shown, a lifting and rotating device for a horizontal cam exchange table, a lifting and rotating device for a horizontal cam exchange table, including a box body 100, a cam transmission mechanism 200, a driving mechanism 300 and a rotating plate 400, on the box body A first insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com