A thermal washing treatment method for oil waste

A treatment method and technology for garbage, applied in combustion methods, chemical instruments and methods, lighting and heating equipment, etc., can solve problems such as pollution, environmental risk hazards, and complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with specific embodiments.

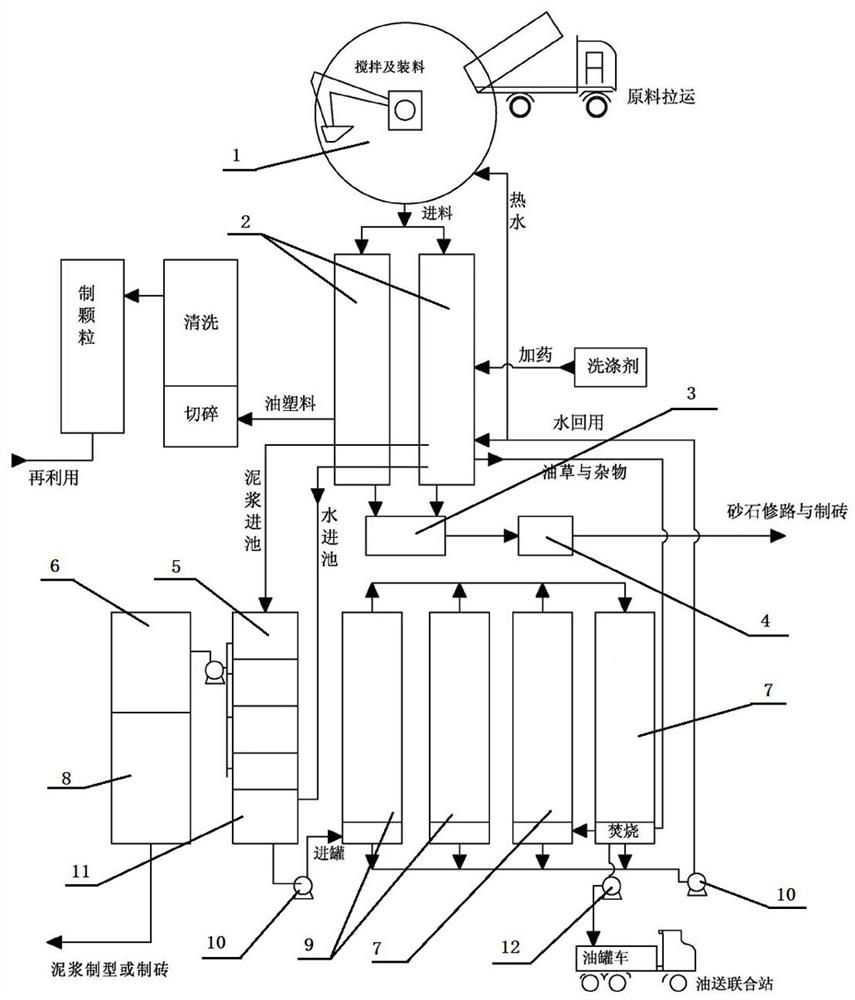

[0025] like Figure 1-10 As shown, soak the raw materials in a 50-90 ℃ hot water pretreatment tank to soften or partially float the oil; there is a grapple machine on the upper part of the pretreatment tank to stir in the pretreatment tank, and then grab the material to the separator for processing next step separation;

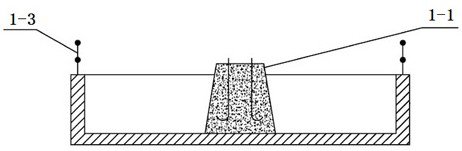

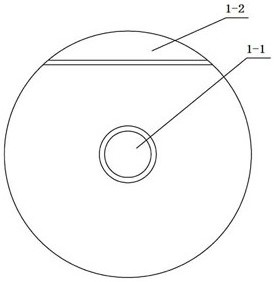

[0026] The pretreatment tank is a concrete tank 1, and there are connections for aeration or water inlet pipes in the middle and around the pretreatment tank. In the middle of the pretreatment tank, there is a grapple base 1-1 for fixing the grapple machine, and the grapple machine is also used for cleaning and pretreatment. For sludge at the bottom of the tank, there is an overflow tank 1-2 on one side of the pretreatment tank. When the water level is higher, the oil and water overflow into the overflow tank 1-2. The notch of the overflow tank 1-2 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com