Extrusion type soil crushing equipment for agriculture

A soil crushing and extrusion technology, which is applied in the agricultural field, can solve the problems of being unsuitable for crop cultivation, low work efficiency, and inability to crush soil, so as to ensure smooth soil falling, reduce labor intensity, and increase crushing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

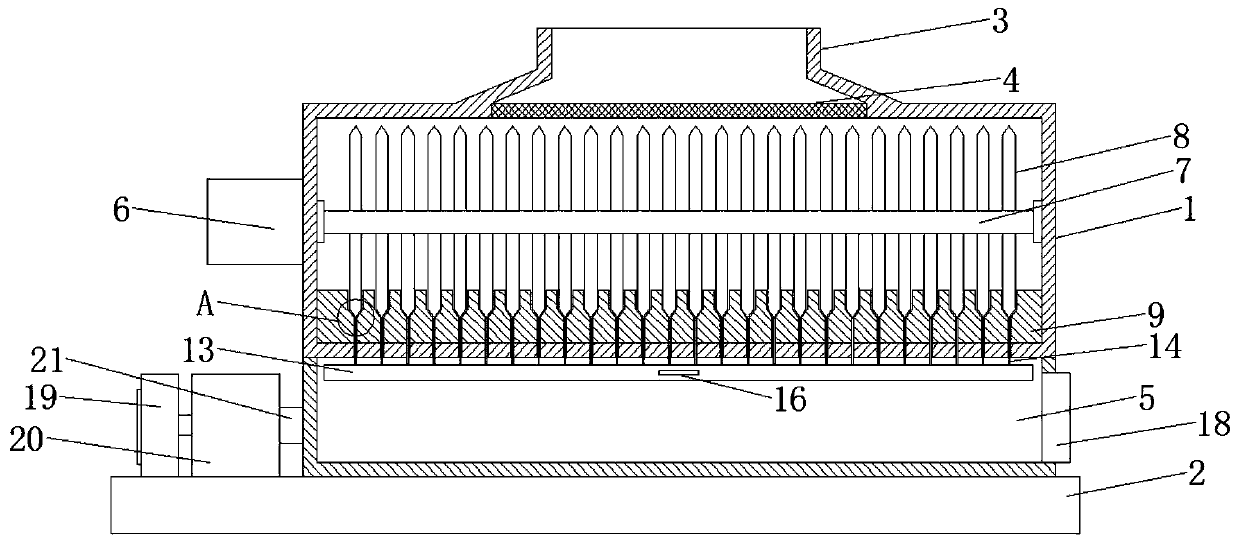

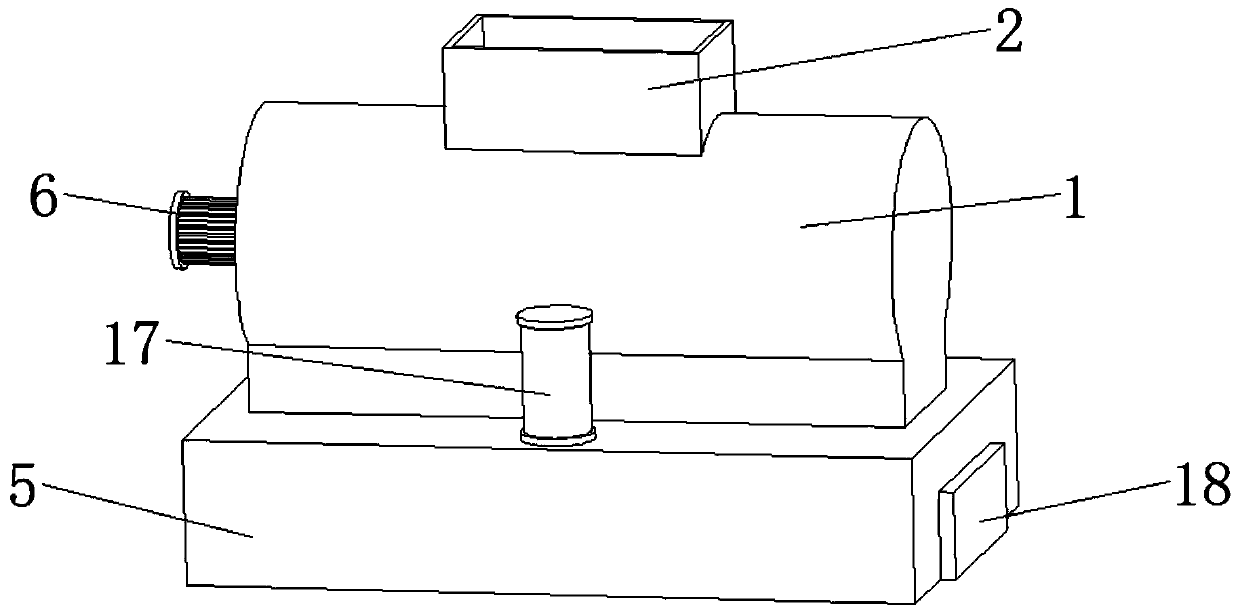

[0023] Please refer to the figure, in the embodiment of the present invention, an agricultural extrusion type soil crushing equipment includes a cylinder body 1, a base 2, a feed port 3, a screen 4 and a collection box 5; the collection box 5 is fixed and installed horizontally On the base 2, a plurality of rollers are installed on the lower side of the base 2, so that the equipment is easy to move; on the top of the collection box 5, a horizontal cylinder 1 is fixedly installed, and the cylinder 1 is a cylindrical structure. The top of the feed port 3 is communicated with a feed port 3 with an opening upward, so that the soil to be pulverized is loaded into the cylinder body 1 from the feed port 3, and the bottom of the feed port 3 is provided with a A neat sieve 4, the soil loaded into the equipment is preliminarily screened through the sieve 4 to prevent the soil from being too large to be crushed, and to protect the internal mechanism.

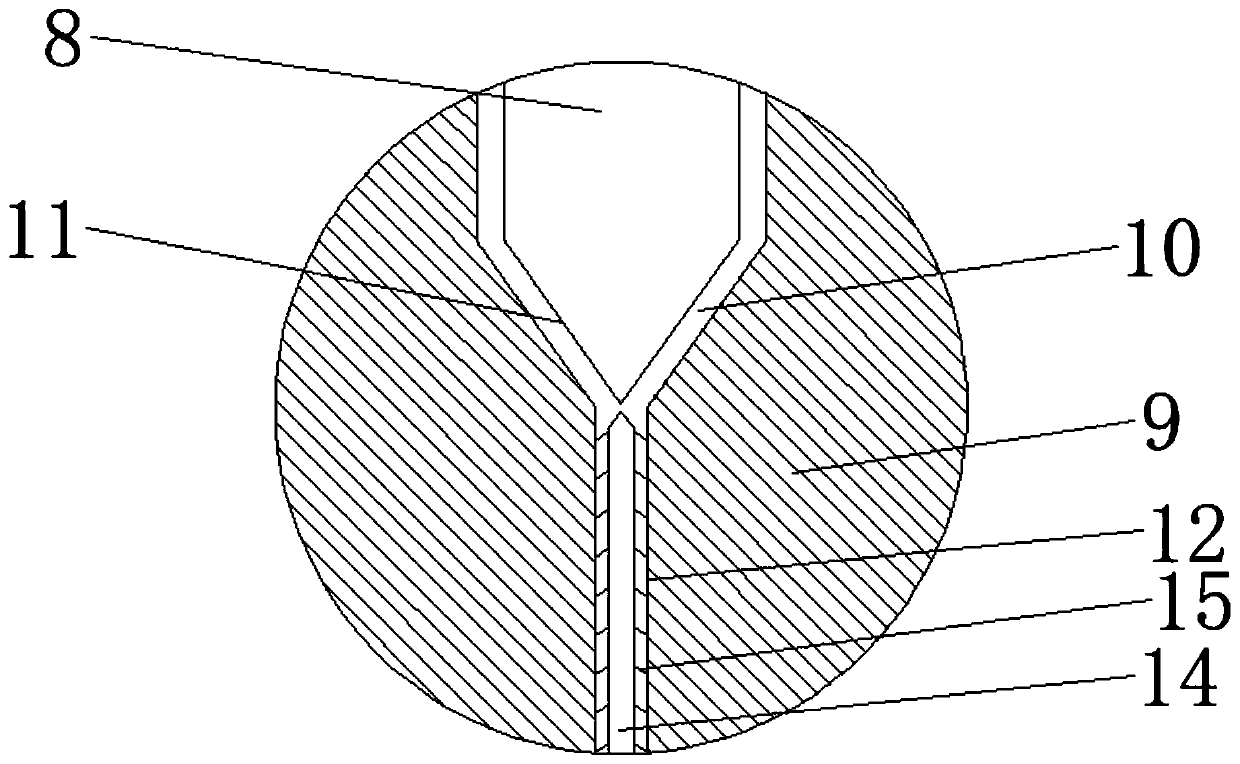

[0024] The central shaft of the cyl...

Embodiment 2

[0026] On the basis of Embodiment 1, a horizontal support lifting rod 13 is arranged in the collection box 5, and a top plate 14 corresponding to the lower chute 12 is fixed on the support lifting rod 13. The length of feed trough 12 is identical, makes top plate 14 integrally enter in the feed chute 12, and the height of top plate 14 is equal to the height of described feed trough 12, and top plate 14 can fully extend in the feed chute 12, is convenient to blanking The soil in the groove 12 falls; the side wall of the top plate 14 is fixedly provided with several blocking material rubber strips 15 in the horizontal direction, the blocking material rubber strips 15 are inclined downward, and the end edge is in line with the bottom edge of the cutting groove 12. Side wall contact can scrape off all the soil on the inner wall of the feeding trough 12 during the downward movement of the top plate 14 to prevent the soil from falling, and also enable the soil to be retained in the e...

Embodiment 3

[0028] In the scheme of embodiment 1 and embodiment 2, an air duct 21 is communicated in the collection box 5, and a heating box 20 and a fan 19 are successively communicated on the air duct 21, and the air inlet of the fan 19 is covered with a dust cover. The air is sent into the inside by the fan 19, heated in the heating box 20, and the hot air is blown in the collection box 5, and the hot air flows upward from the feeding chute 12 into the cylinder 1 to dry the soil inside.

[0029]The soil loaded from the feed port 3 is first screened by the screen 4 and falls into the cylinder 1. The soil in the cylinder 1 falls on the extrusion plate 9 at the bottom, and the motor 6 drives the extrusion blade 8 at the same time. Rotate, the edge of extrusion blade 8 rotates in extrusion groove 10, and the soil on the upper surface of extrusion plate 9 falls along the blanking gap 22 of extrusion blade 8, squeezes with the side wall of extrusion groove 10 in blanking gap 22 Pressing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com