A cement cracking device and concrete production system

A shell-breaking device and concrete technology, which is applied in clay preparation devices, clay processing equipment, chemical instruments and methods, etc., can solve the problems of low cement utilization rate, increase concrete strength, avoid blade stocking, and improve cement utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

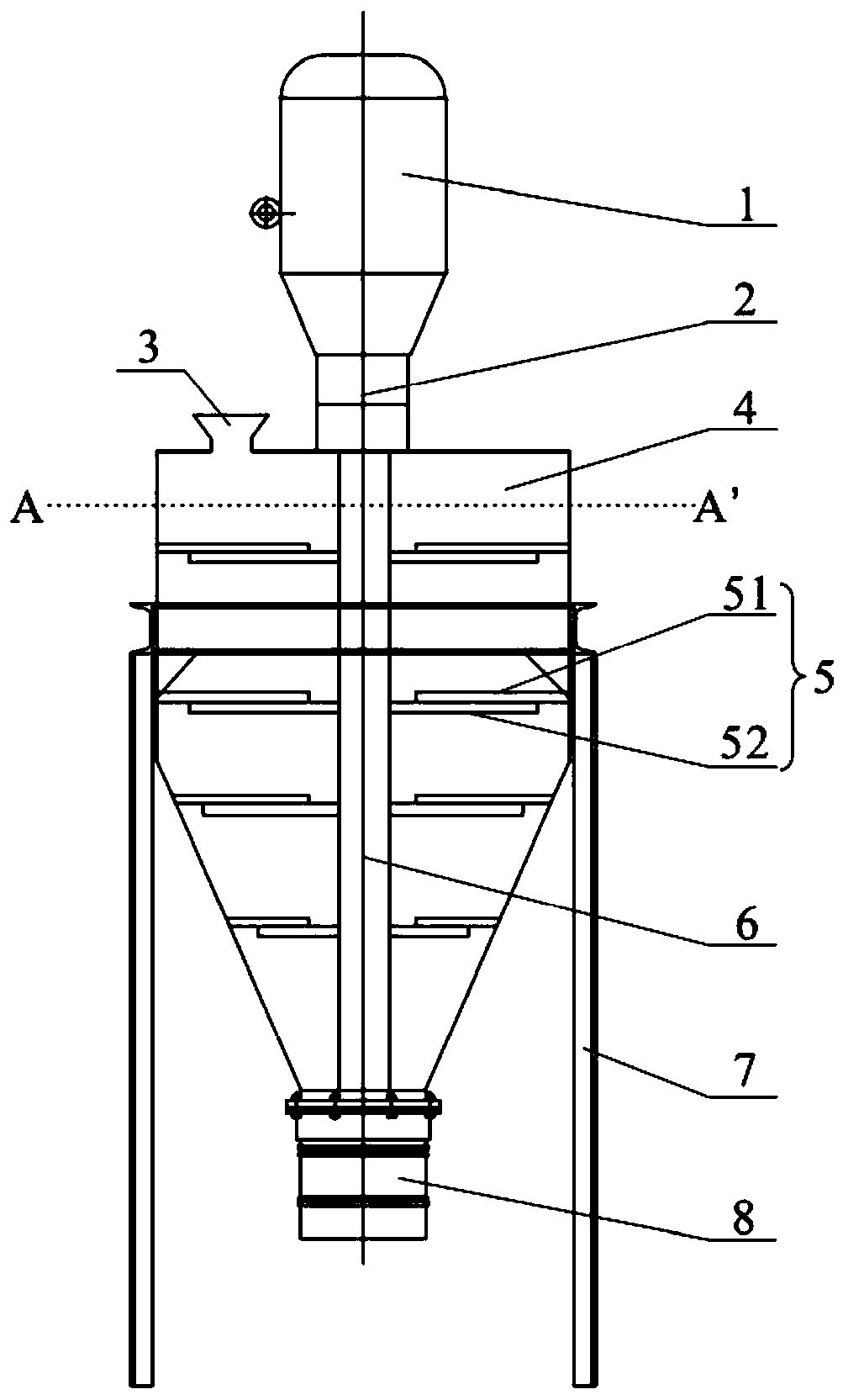

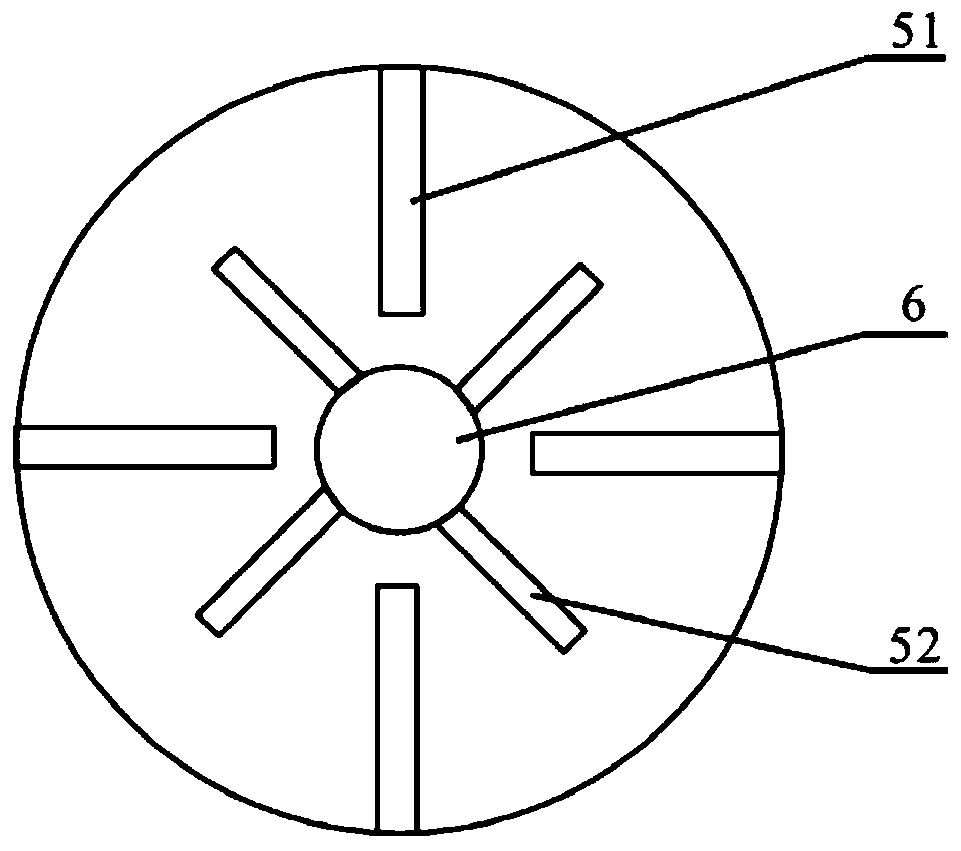

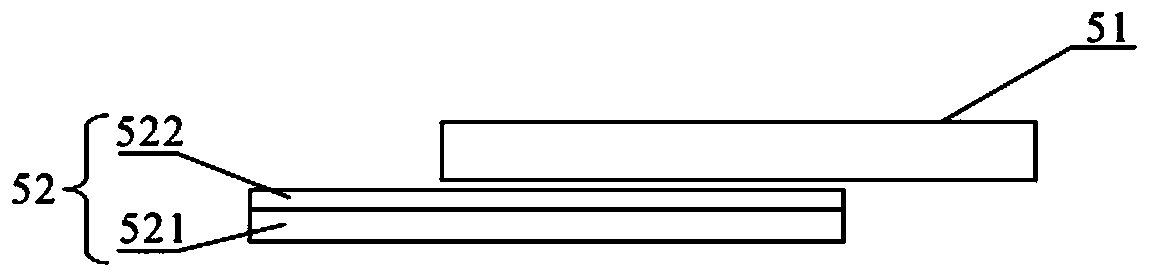

[0034] This embodiment provides a cement shell breaking device, such as Figure 1 to 5 As shown, it includes a bucket body 4, a rotating shaft 6 is arranged inside the bucket body 4, one end of the rotating shaft 6 is connected to the motor 1, and at least one set of cutting and sharpening knife assemblies 5 are arranged in the bucket body 4, and the cutting and sharpening knife assembly 5 includes a fixed The blade 51 and the rotating blade 52, one end of the fixed blade 52 is fixedly connected to the inner wall of the bucket body 4, and one end of the rotating blade 52 is fixedly connected to the outer peripheral surface of the rotating shaft 6; the fixed blade 51 and the rotating blade 52 are in the axial direction of the bucket body 4 The orthographic projection of has overlapping parts.

[0035] During implementation, after cement enters the bucket 4, it falls due to gravity. The motor 1 drives the rotating shaft 6 to rotate through the coupling 2, and the rotating blade 52 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com