Constant-force comb falling cutter with self-adaption to banana fruit shafts based on extensible mechanism

A self-adaptive, drop-comb technology, which is applied in the field of fixed-center, large-stroke, variable-diameter, self-adaptive banana fruit shaft-by-comb and off-axis profiling drop-comb fields, which can solve the problem of missing banana comb handles, small variable diameter stroke, and self-adaptive banana fruit shafts. Poor adaptation and other problems, to achieve the effect of auxiliary retraction and reset, uniform force on the tool, and constant clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

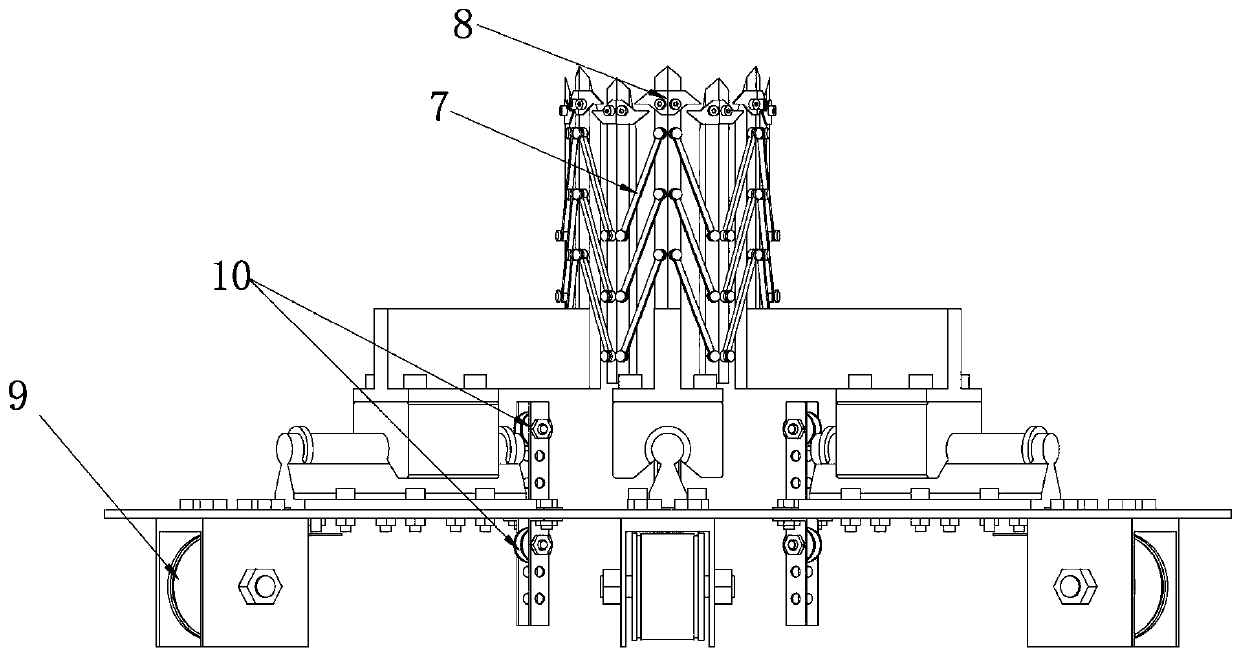

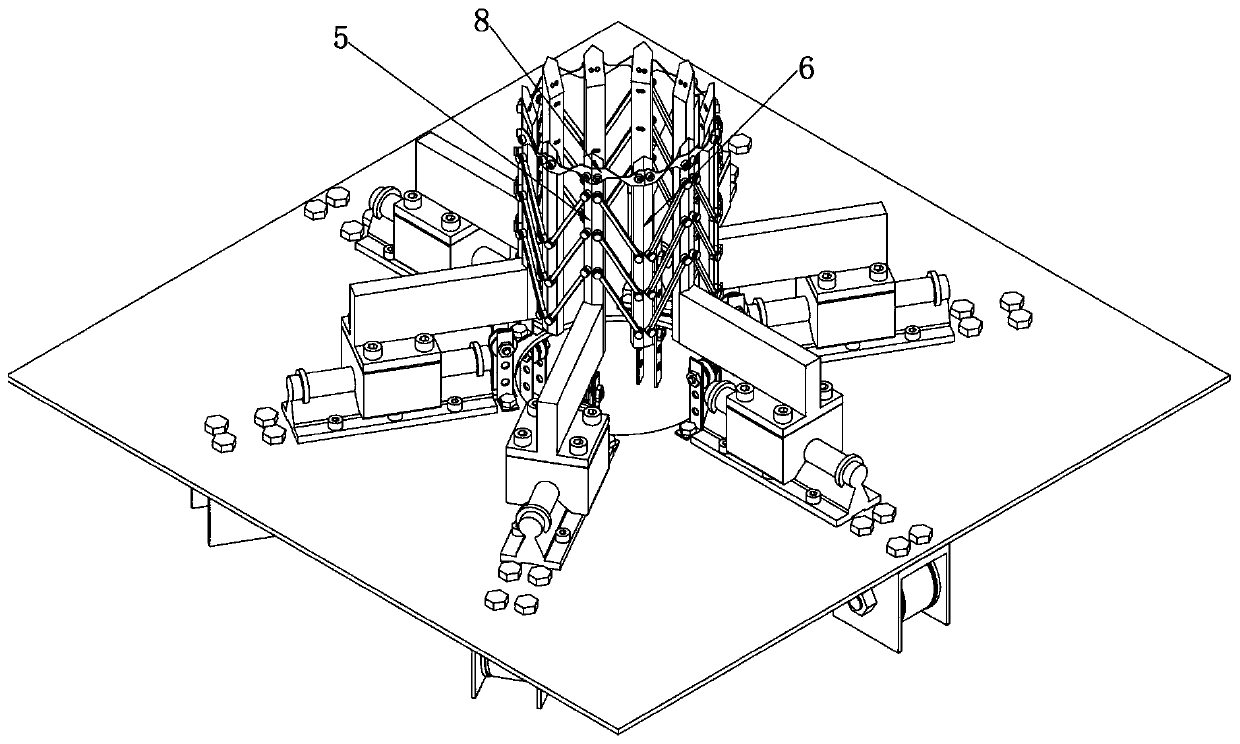

[0021] Such as Figure 1 to Figure 5 As shown, the constant-force combing tool based on the adaptive banana fruit shaft of the expandable mechanism described in this embodiment includes a combing cutter head 1, an SBR aluminum support linear guide rail 2, an SBR slider 3, and a main hard tool connection. Block 4, main hard blade 5, auxiliary hard blade 6, connecting rod 7, soft blade 8 and constant force assembly; The center of described falling comb cutter head 1 is provided with for the banana fruit shaft after falling comb to pass through The through hole; the power source (not shown) is a plurality of impact cylinders, and is evenly distributed on the bottom of the combing cutter head 1 around the center circumference of the through hole of the combing cutter head 1, and the combing cutter head 1 It is driven by the power source at the bottom to move upward or downward as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com