A kind of high whiteness and high coating rate coil white finish paint and its preparation method and application

A coating rate, high whiteness technology, applied in coatings, polyester coatings, etc., can solve the problems that affect the physical and chemical properties of coatings and weather resistance, whiteness and hiding power, and cannot satisfy high-end customers. Outdoor chalking resistance, easy application, high whiteness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

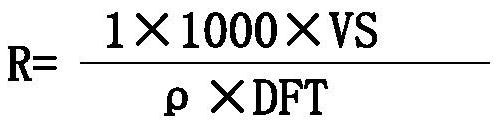

Method used

Image

Examples

preparation example Construction

[0056] In a preferred example, in the preparation method of the saturated polyester resin A, between step 1) and step 2), it also includes adding 1-8 parts by weight of xylene into the reaction kettle until the material acid Value<10KOHmg / g is the step of reaction end point.

[0057] In a preferred example, the saturated polyester resin A has a number average molecular weight of 1500-2500, a PDI of 2-2.6, a hydroxyl value of 110-140 mgKOH / g, a mass solid content of 75-85%, and a viscosity of X- Z2. Exemplarily, the number average molecular weight of the saturated polyester resin A includes but is not limited to 1500-2000, 1900-2500, 1900-2500, 1900, 2000 and the like. Exemplarily, the hydroxyl value of the saturated polyester resin A is 110-130 mgKOH / g, 110-120 mgKOH / g, 120-130 mgKOH / g, 110 mgKOH / g, 130 mgKOH / g, etc.

[0058] In yet another preferred example, the flexible saturated polyester resin B has a number average molecular weight of 2500-3500, a PDI of 3-3.5, a hydrox...

Embodiment 1

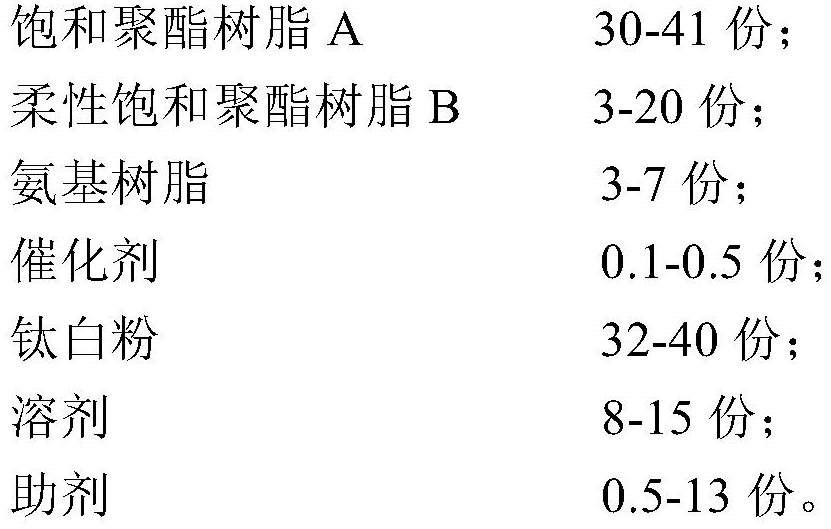

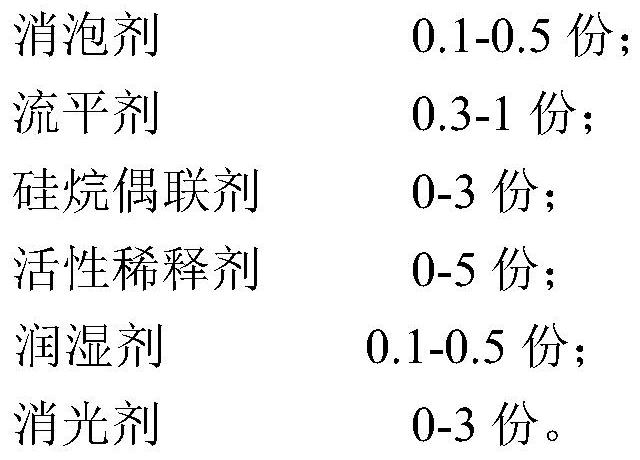

[0089] High whiteness and high coating rate coil white topcoat, its raw materials are shown in Table 1 below.

[0090]The preparation method of high whiteness and high coating rate coil white topcoat comprises the following steps:

[0091] (1) Premixing: Add part A in Table 1 to the container of the high-speed mixer in turn, and start stirring;

[0092] (2) Wetting and dispersing: Add B under stirring conditions, and after the titanium dioxide is wetted, add glass beads, and it is difficult to control the fineness test time according to the titanium dioxide dispersion, control the fineness at 15-20um, and stop the dispersion.

[0093] (3) Thinning: After filtering the glass beads in the sand grinding slurry, calculate the yield, add C while stirring in a new container, and continue to stir evenly.

[0094] (4) Preparation of high-gloss paint: use mixed solvent a or mixed solvent b to dilute directly, viscosity 110-120s (coat 4 cups / 25°C), and then get high-gloss white finish ...

Embodiment 2-8

[0101] High whiteness and high coating rate coil white topcoat, its raw materials are shown in Table 1 below. Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com