Preparation method of polyvinyl alcohol phytate

A technology of polyvinyl alcohol phytate and polyvinyl alcohol, which is applied in the field of preparation of polyvinyl alcohol phytate, can solve the problems of difficult modification and modification of phytic acid molecules, and achieves improved coordination ability, high electronegativity, Rich application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

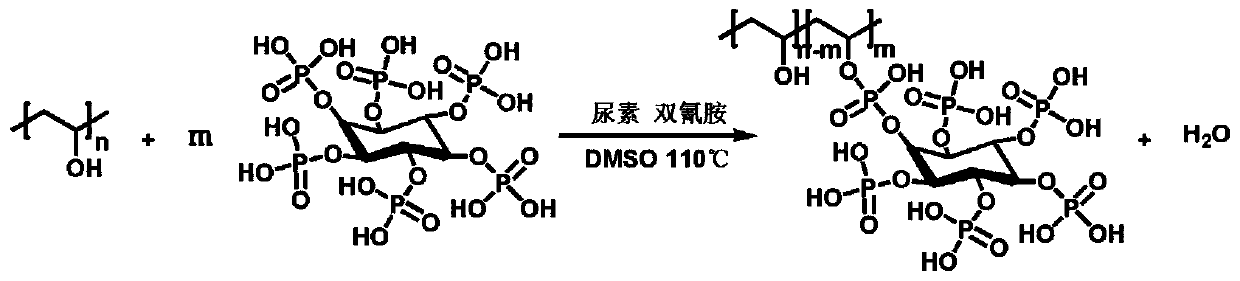

[0020] In view of the above-mentioned shortcomings, in order to solve the shortcomings of the existing phytic acid molecules that are difficult to modify and modify, and utilize the strong coordination ability of phytic acid and metal ions. The invention provides a preparation method of polyvinyl alcohol phytate and metal ion coordination hydrogel

[0021] Polyvinyl alcohol phytate is prepared by the esterification reaction between the hydroxyl group on the polyvinyl alcohol polymer chain and the phosphoric acid group on the phytic acid molecule, in which dimethyl sulfoxide (DMSO) is the solvent and urea is the catalyst. The water in the system will inhibit the positive progress of the esterification reaction, so it is necessary to add dicyandiamide as a dehydrating agent and toluene as a water-carrying agent

[0022] Polyvinyl phytate can be achieved through the following technical solutions:

[0023] A kind of preparation method of polyvinyl alcohol phytate, its preparation...

Embodiment 1

[0038] In parts by weight, 3 g of polyvinyl alcohol solid particles, 0.36 g of urea, 0.14 g of dicyandiamide and 150 mL of dimethyl sulfoxide (DMSO) were added into a three-necked flask, and a condensation device and a nitrogen protection device were set up. Heat and stir at 110°C until completely dissolved, then add 1 mL of 50% phytic acid solution and 0.1 mL of toluene;

[0039] After the reaction, the supernatant in the three-necked flask was dropped into absolute ethanol drop by drop, and the precipitate was collected and washed with absolute ethanol and acetone for several times until the pH of the filtrate was neutral; the precipitate was vacuum-dried at 60° C. for 48 h.

Embodiment 2

[0041] In parts by weight, 3 g of polyvinyl alcohol solid particles, 1.78 g of urea, 0.71 g of dicyandiamide and 150 mL of dimethyl sulfoxide (DMSO) were added to a three-necked flask, and a condensation device and a nitrogen protection device were set up. Heat and stir at 110°C until completely dissolved, then add 5 mL of phytic acid solution with a mass fraction of 50% and 0.5 mL of toluene;

[0042] After the reaction, the supernatant in the three-necked flask was dropped into absolute ethanol drop by drop, and the precipitate was collected and washed with absolute ethanol and acetone for several times until the pH of the filtrate was neutral; the precipitate was vacuum-dried at 60° C. for 48 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com